GWH 2400 ES NG, GWH 2400 ES LP specifications

Bosch Appliances has established a reputation for delivering high-quality and innovative home solutions, and the Bosch GWH 2400 ES LP and GWH 2400 ES NG are no exceptions. These high-efficiency water heaters are designed to provide on-demand hot water, ensuring comfort and convenience for your home.One of the standout features of the Bosch GWH 2400 ES LP (Liquid Propane) and GWH 2400 ES NG (Natural Gas) models is their compact, space-saving design. These tankless water heaters are engineered to fit in smaller spaces, making them an ideal choice for homes with limited installation areas. Despite their compact size, both models provides a powerful performance that meets the hot water needs for multiple fixtures simultaneously, such as showers, faucets, and washing machines.

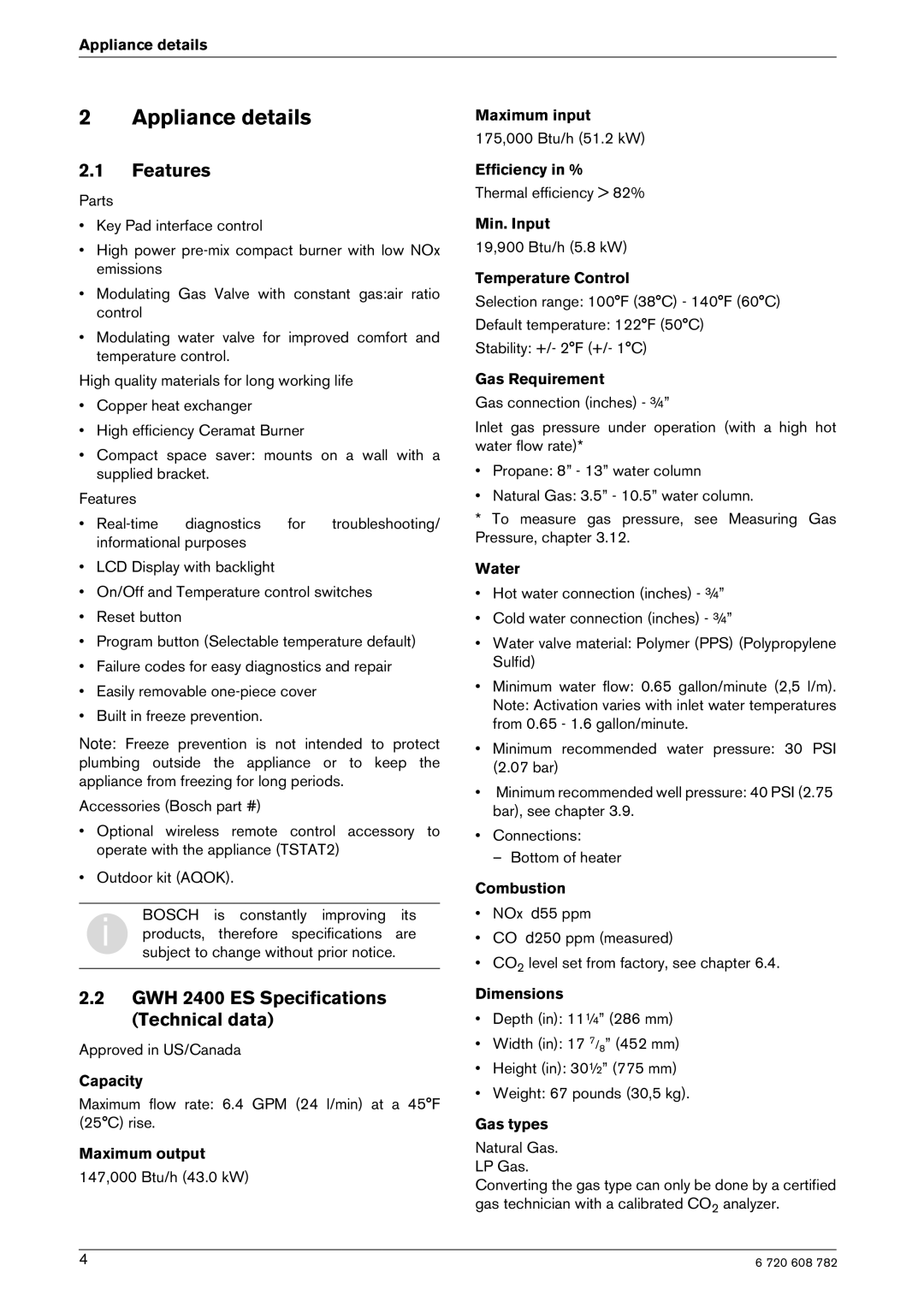

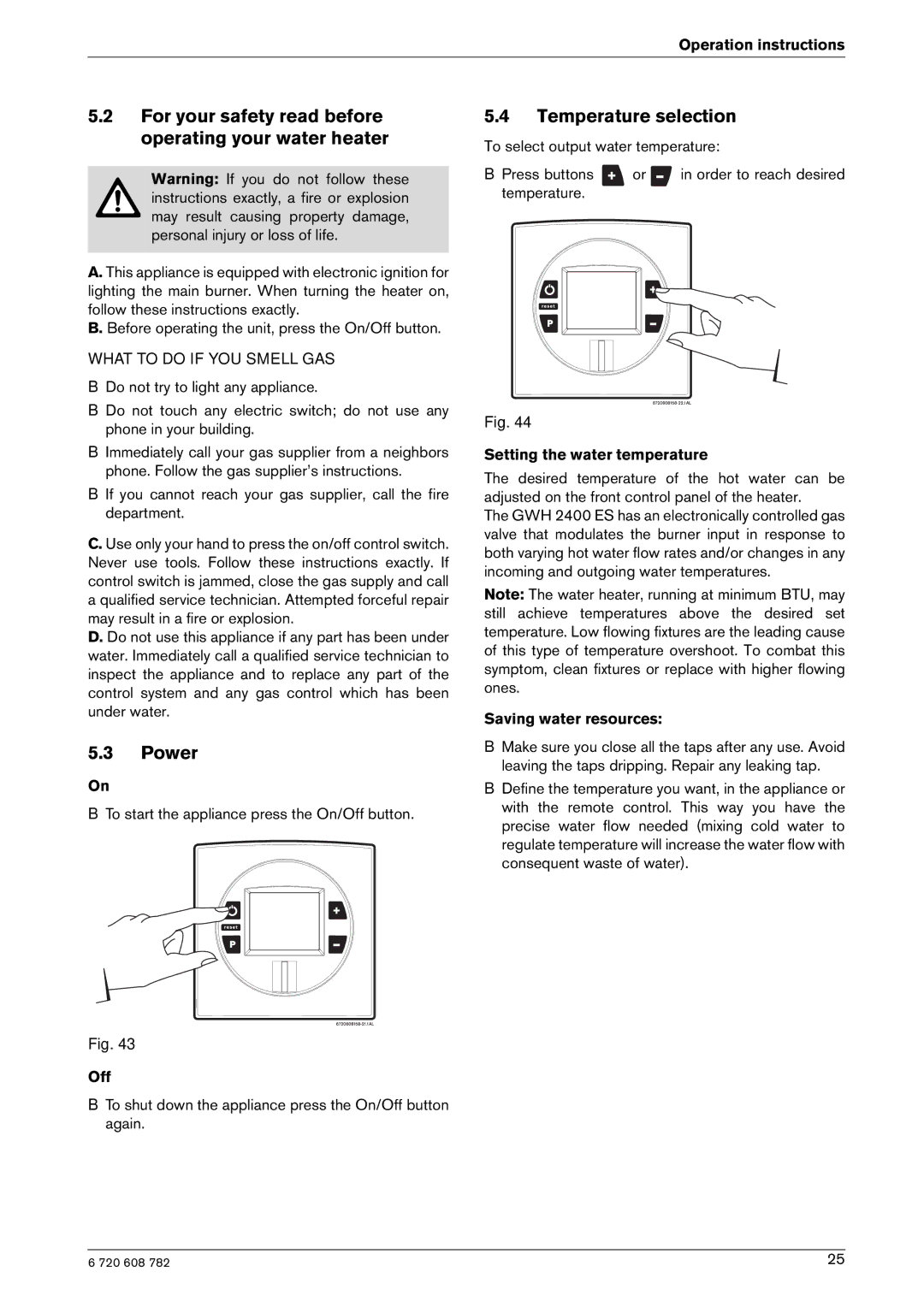

These water heaters are equipped with advanced technology that enables precise temperature control. The Bosch GWH 2400 ES series utilizes a microprocessor-based control system that allows for consistent water heating, ensuring the water temperature remains stable even during high demand. The modulating gas valve further optimizes energy consumption, adjusting the flame intensity to meet the exact heating needs, thus enhancing efficiency.

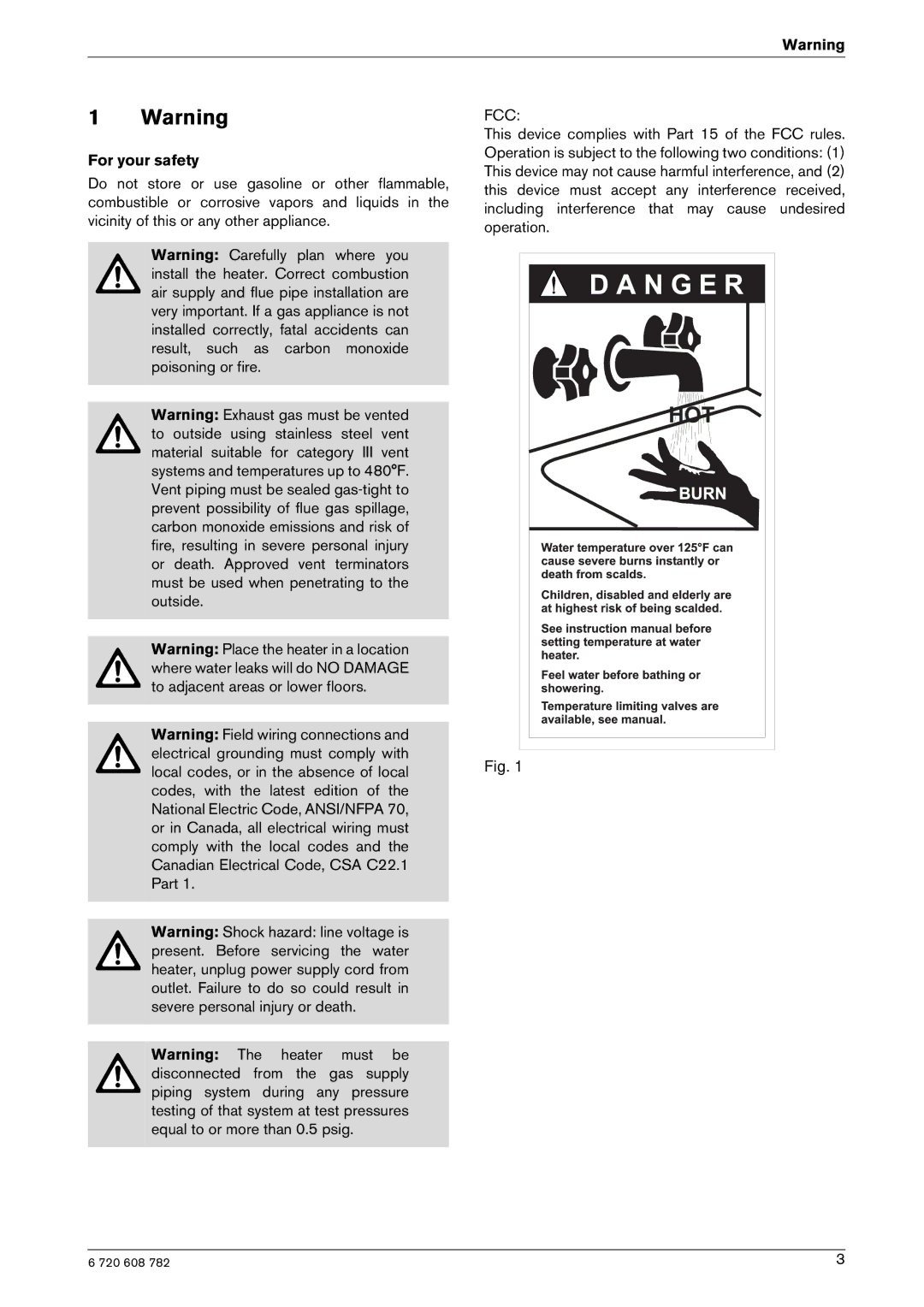

In terms of safety, both the GWH 2400 ES LP and NG come with multiple safety features. These include a flame failure safeguard, overheating protection, and a built-in freeze protection system. Such features ensure both peace of mind and the longevity of the unit.

Installation is straightforward with these models, as they can be vented using standard venting materials, saving time and costs. Additionally, the units boast a low NOx emissions rating, making them environmentally friendly choices that help homeowners reduce their carbon footprint.

Maintenance is minimal, thanks to the corrosion-resistant heat exchanger which ensures durability and long service life under normal operating conditions. This factor, combined with Bosch’s renowned commitment to quality, makes these models a reliable investment for any household.

Whether you opt for the GWH 2400 ES LP or the GWH 2400 ES NG, you will experience the benefits of a powerful, efficient, and safe water heating solution tailored to your specific household needs. Bosch has truly combined technology, sustainability, and user comfort in these innovative models, solidifying their place as leaders in the home appliance market.