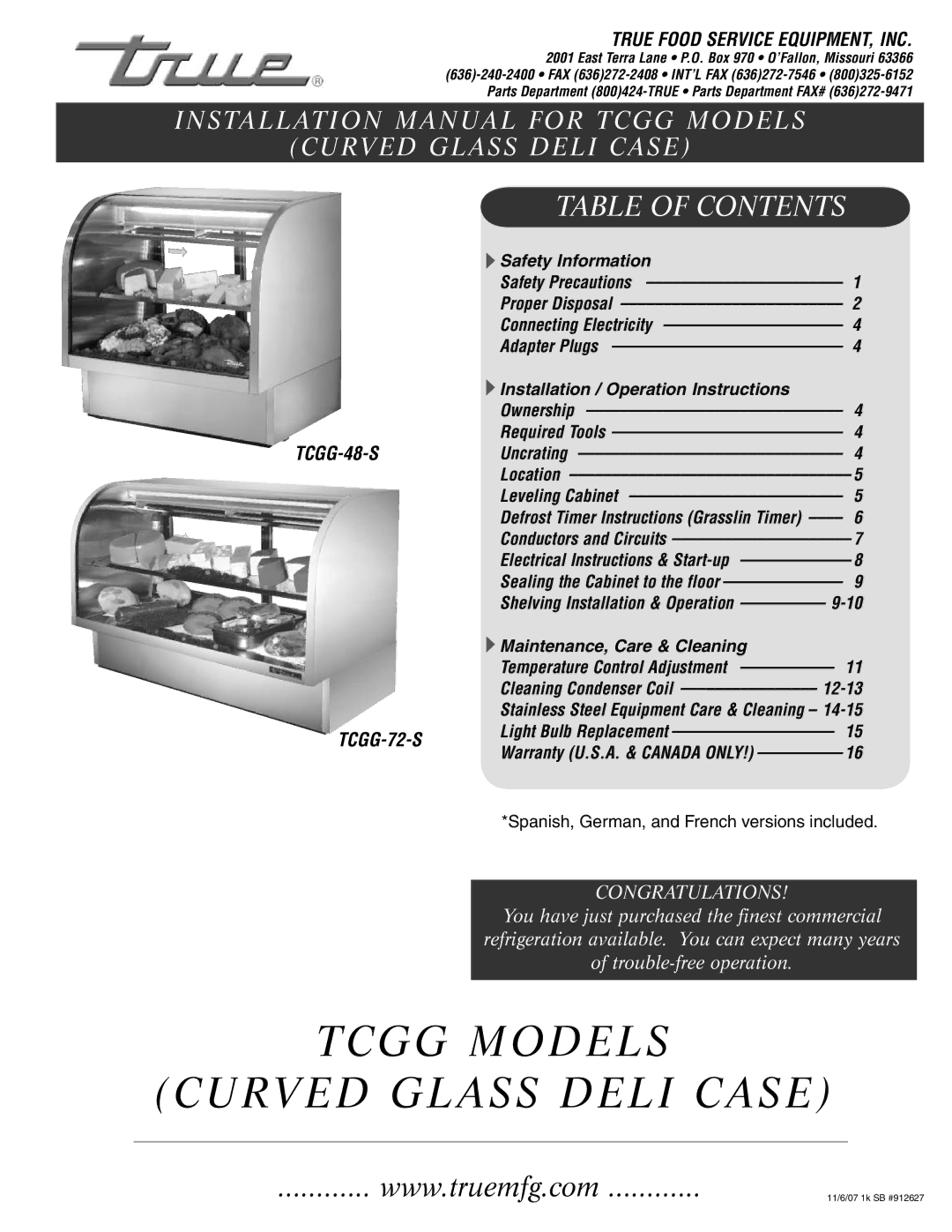

TCGG-48-S, TCGG-72-S specifications

True Manufacturing Company is known for its commitment to quality and innovation in the refrigerated equipment market. Among its notable products are the TCGG-72-S and TCGG-48-S models. These commercial glass door freezers are designed to meet the diverse needs of restaurants, bars, and grocery stores looking to display frozen products while ensuring optimal performance.The True TCGG-72-S features a spacious 72-inch width, offering ample storage for a variety of frozen items. It is equipped with triple glass doors, which allow for easy visibility and access to products. This model has a significant storage capacity, making it ideal for businesses with high demand for frozen goods. The TCGG-48-S, on the other hand, is a more compact 48-inch unit, suitable for smaller spaces without sacrificing performance. Both models are designed with energy efficiency in mind, employing True's innovative refrigeration system that maintains consistent temperatures while minimizing energy consumption.

Key technologies embedded in both models include a powerful and efficient compressor that ensures the freezers operate quietly and efficiently. True's patented reverse condensing fan motor and self-cleaning condenser technology help reduce maintenance efforts, extending the lifespan of the unit. This design feature not only improves reliability but also enhances overall hygiene by preventing the buildup of dust and debris.

Both the TCGG-72-S and TCGG-48-S models incorporate LED lighting, providing bright illumination that enhances product visibility. This strategic lighting arrangement not only highlights the products on display but also contributes to a visually appealing presentation, attracting customers' attention.

Constructed with a heavy-duty stainless steel exterior and aluminum interior, these units are built to withstand the rigors of a busy commercial kitchen or retail environment. The glass doors are double-pane and filled with a low-conductivity gas to ensure minimal temperature fluctuation during opening and closing, maintaining product integrity and frost-free operation.

In summary, the True Manufacturing Company’s TCGG-72-S and TCGG-48-S models stand out for their durability, energy efficiency, and user-friendly features. Their advanced technologies and thoughtful design make them essential assets for any business aiming to showcase frozen inventory effectively while keeping operational costs low.