Troubleshooting & Repair

Figure 12. Removing the Shredder Hopper

Repair

Shredding Hammer Rotation and Replacement

The cutting edges of the shredding hammers may eventually wear out requiring rotation of the hammer or replacement if all cutting edges have been dulled.

Triangular hammers can be rotated twice after the first edge dulls, then flipped over once and rotated again for a total of 6 edges.

To rotate the shredding hammers:

1.Turn the engine off and wait for all moving parts to stop.

2.Disconnect the spark plug wire and secure it away from the spark plug.

3.Detach the shredder hopper from the rotor housing (Figure 12).

![]() WARNING

WARNING

To avoid serious injury from accidental starting, always disconnect the spark plug wire and secure it away from the spark plug when servicing the unit.

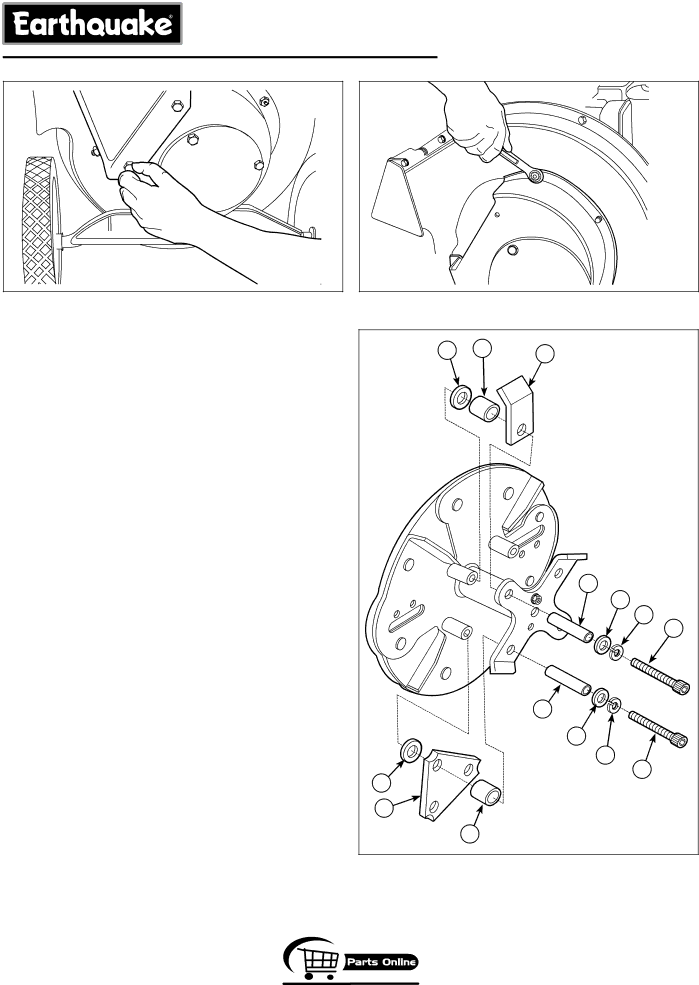

4.Remove the rotor cover by removing the hardware that secures it to the main housing (Figure 13).

5.Note the assembly sequence of the hardware used to secure the hammers (Figure 14). Using a 5/16” allen wrench remove the socket head capscrew (A) and related hardware.

6.Inspect the hammers (G, H), spacer tubes (D, E), and hardware. If the spacer tube (D, E) shows signs of wear, replace it. Inspect and flip, or replace the hammers (G, H).

7.Reassemble the hammers, spacers, washers, and

Figure 13. Removing the Rotor Housing

F | E | G |

|

| D |

|

| C |

|

| B |

|

| A |

|

| D |

|

| C |

|

| B |

F |

| A |

|

| |

H |

|

|

| E |

|

Figure 14. Removing Rotor Housing | E. | Spacer, Short | |

A. | Socket Hd. Capscrew | F. | Washer, 3/8 (9070300, |

B. | Lockwasher, 3/8 |

| 9010400, 9010140 only) |

C. | Washer, 7/8 | G. | |

D. | Spacer, Long | H. | Triangular Hammer |

GetEarthquake.com

Page 23