SECTION V - MAINTENANCE AND STORAGE

IMPORTANT: The knife should be checked for sharpness and the nuts and bolts attaching them to the flywheel for tightness every

IMPORTANT: Every time you perform maintenance or any kind of service or check on the knife, be sure to check the gap between the knife and wear plate for proper setting.

NOTE: A knife gauge has been provided with your machine. It is 1/16th” thick and should be used to set the correct gap between the knife and wear plate.

If the cutting mechanism strikes any foreign object or if your machine should start making an unusual noise or is vibrating, stop the engine, disconnect both spark plug wires from the spark plugs. Allow the engine to cool before you;

a.Inspect and examine for obvious damage.

b.Check for loose parts, bolts, and nuts.

1.When not in use, your chipper should be stored out of the reach of children. Be sure there are no gasoline fumes in the storage area. For long periods of storage (over winter), refer to the engine owner’s manual.

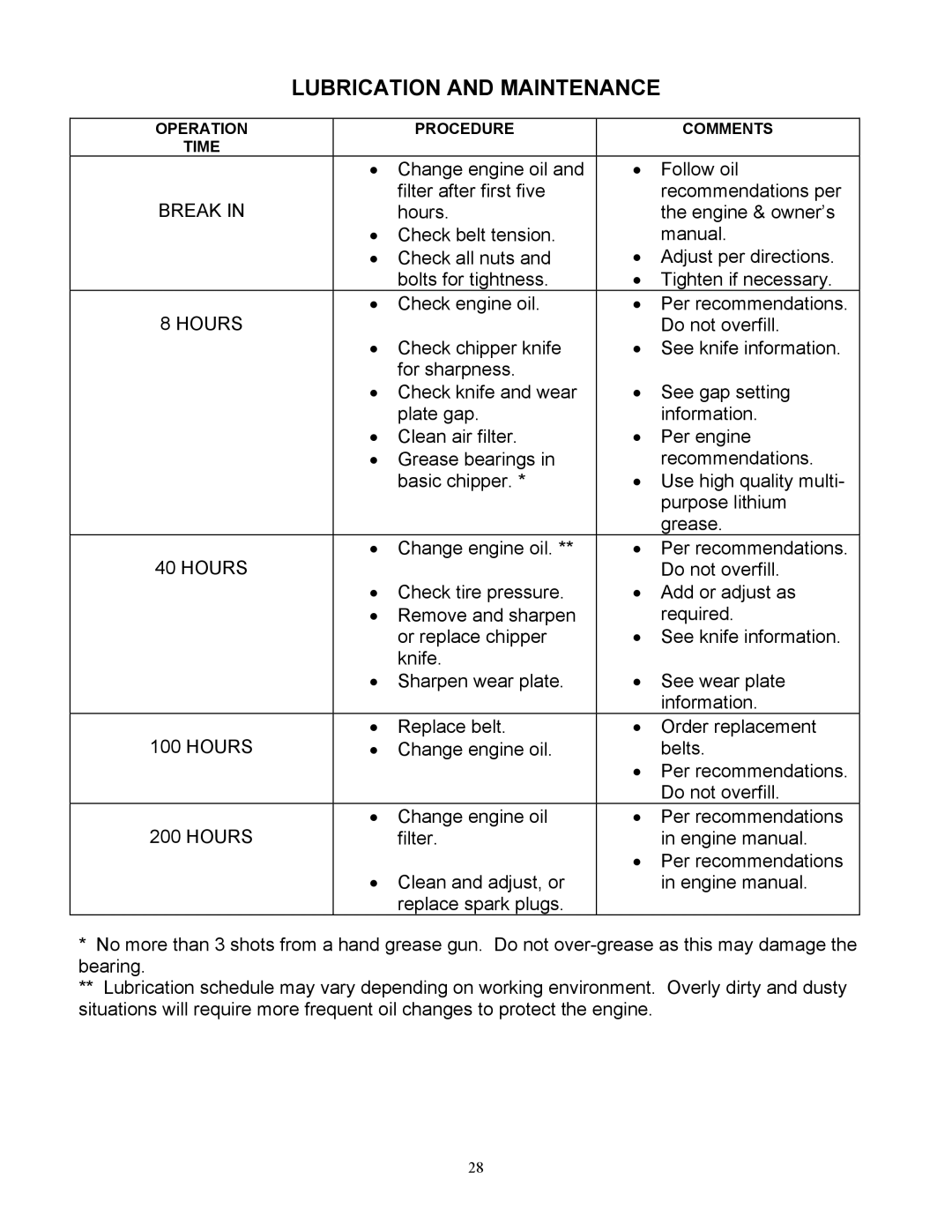

2.After every 8 hours of operation, lubricate the chipper side and drive side bearings. To do this, wipe all dirt, etc., from the grease fittings with a clean cloth, then apply no more than 3 shots of quality

3.You will find information included referring to operation and maintenance of the chipper engine. Look it over carefully. BE CERTAIN TO SERVICE THE ENGINE BEFORE YOU START IT.

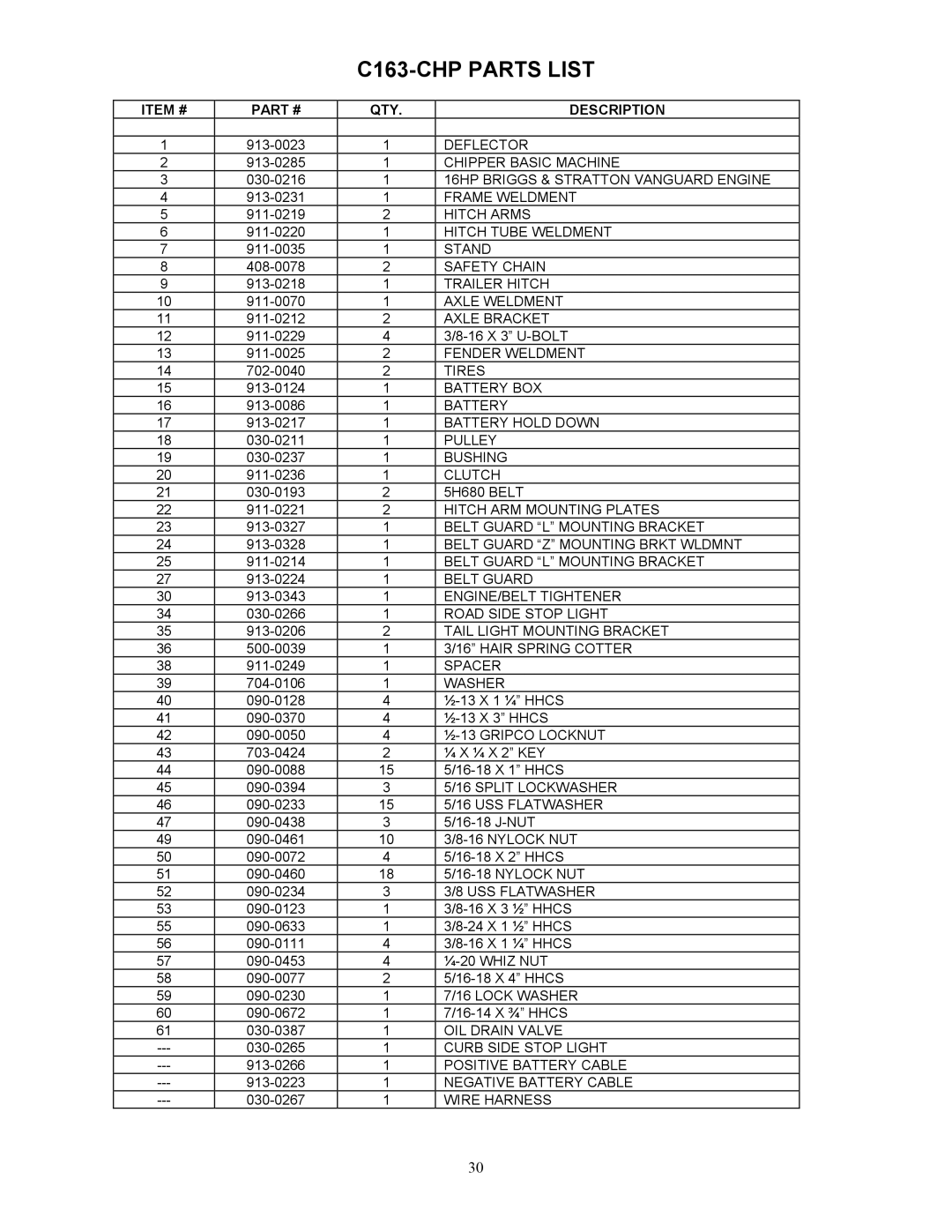

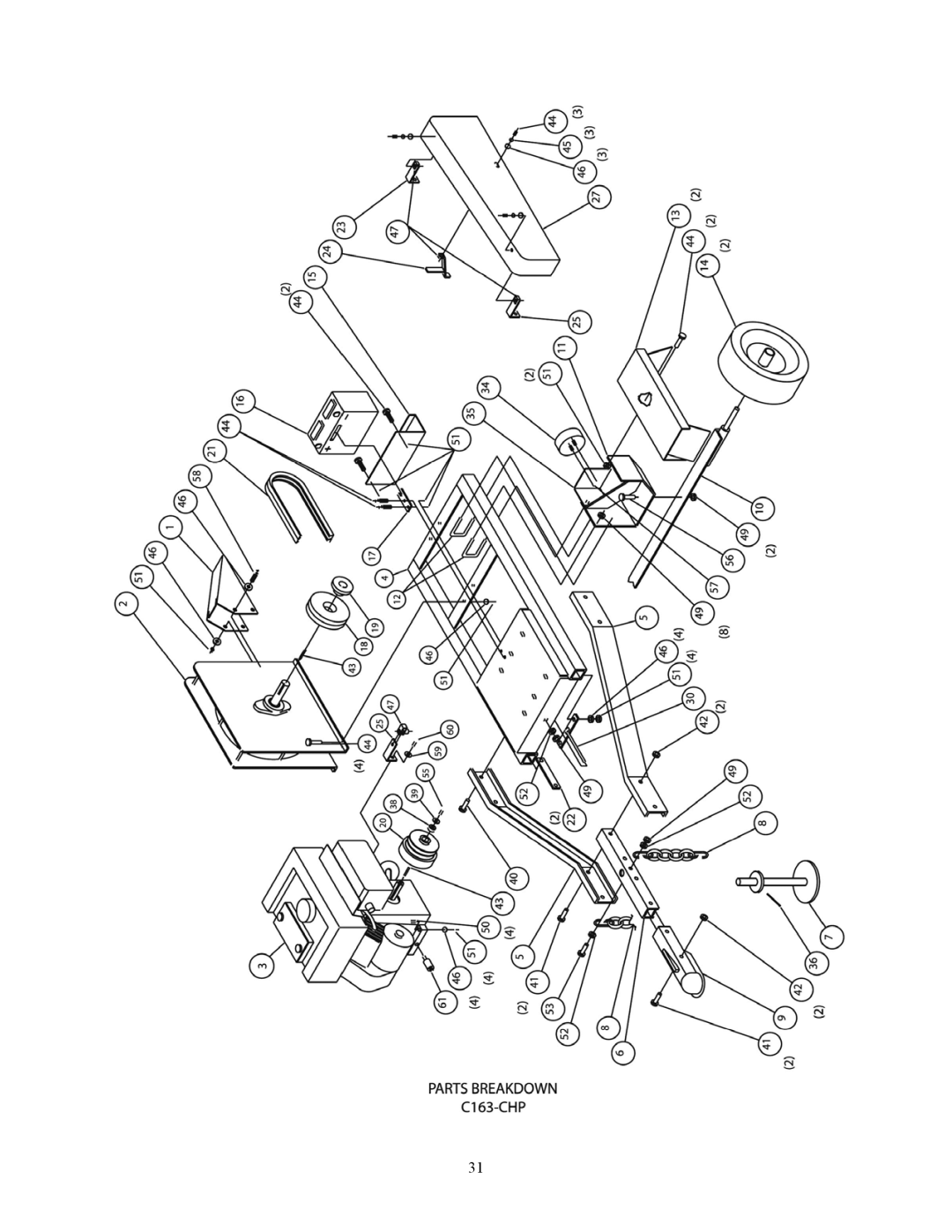

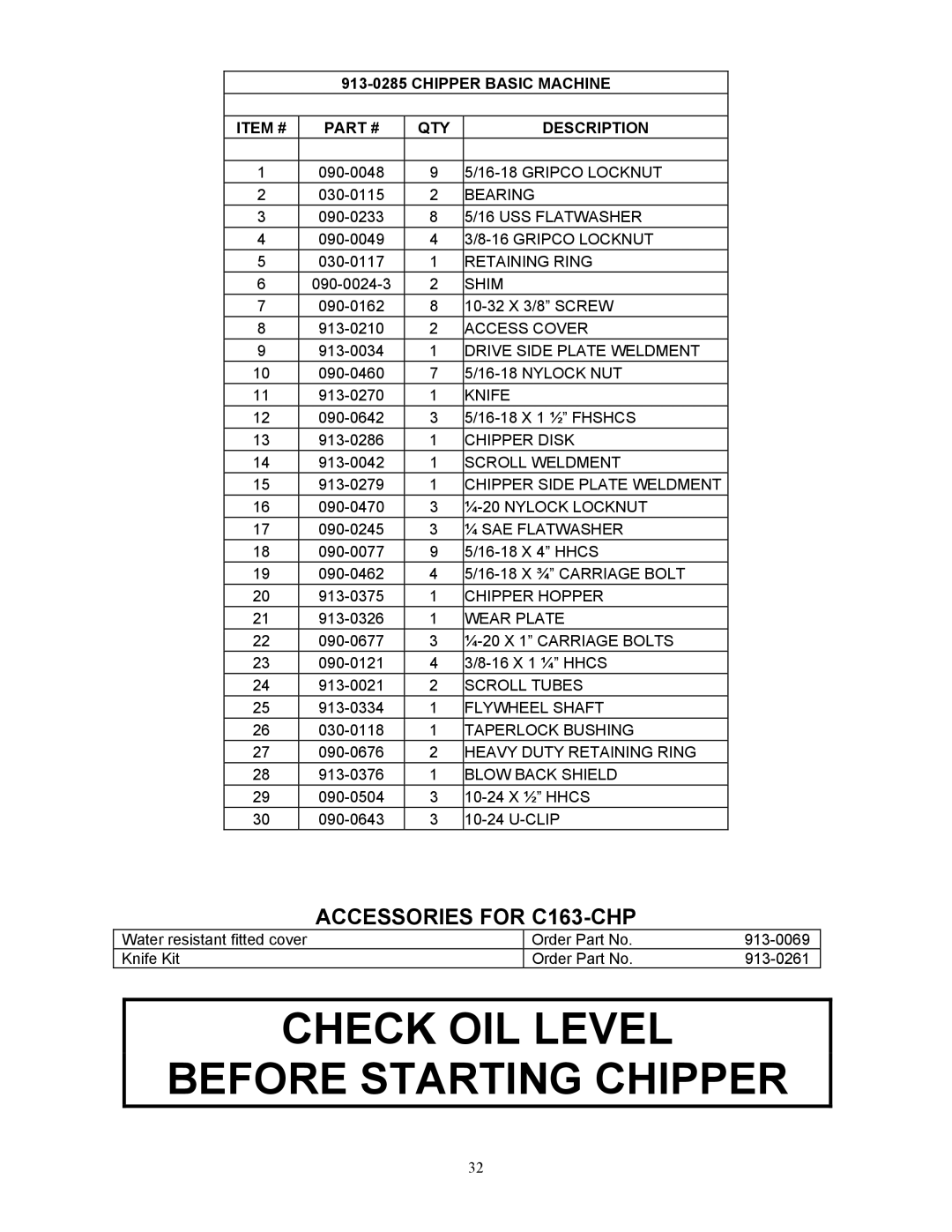

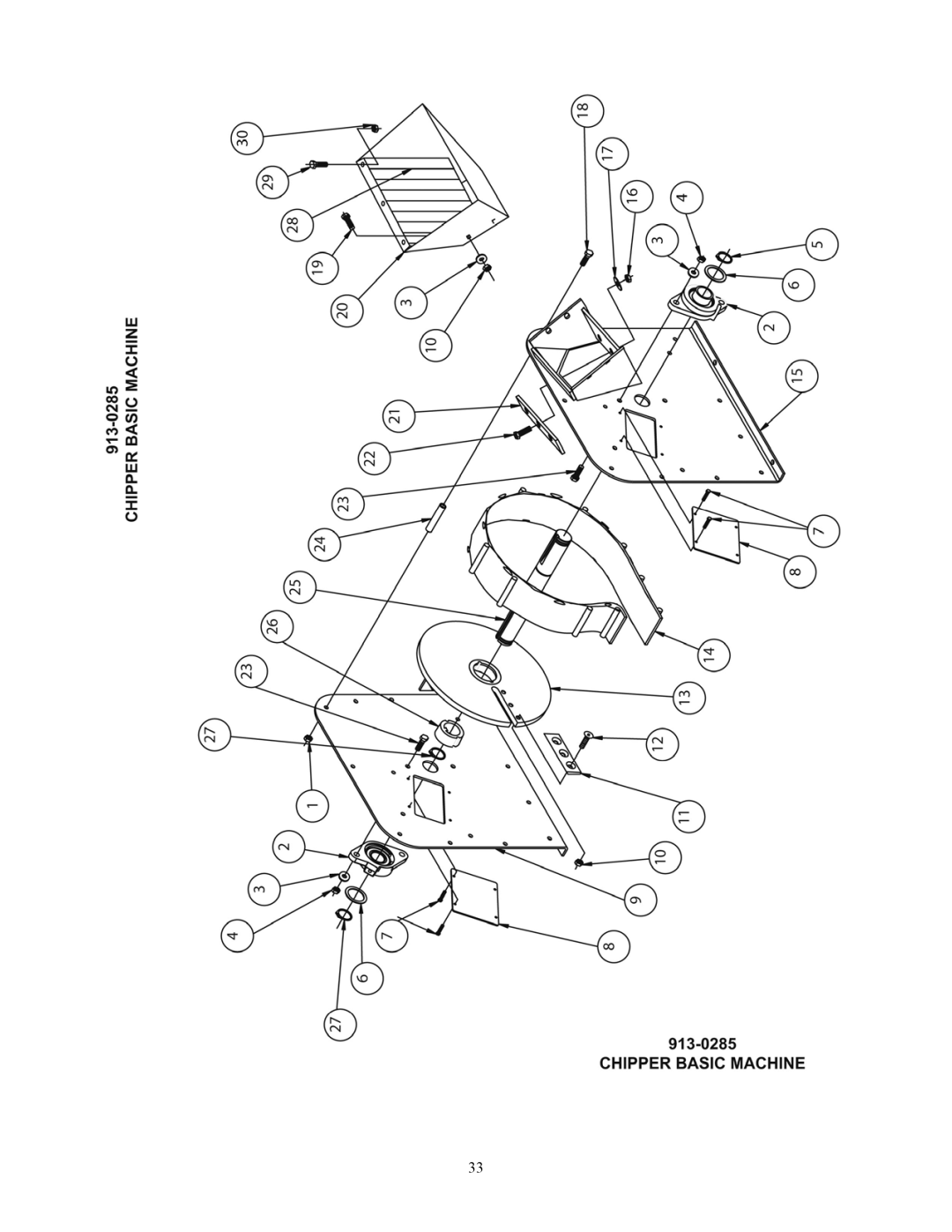

4.When the steel chipping knife (item #11, pg. 32) needs replacing or sharpening, refer to the section on removal, sharpening and

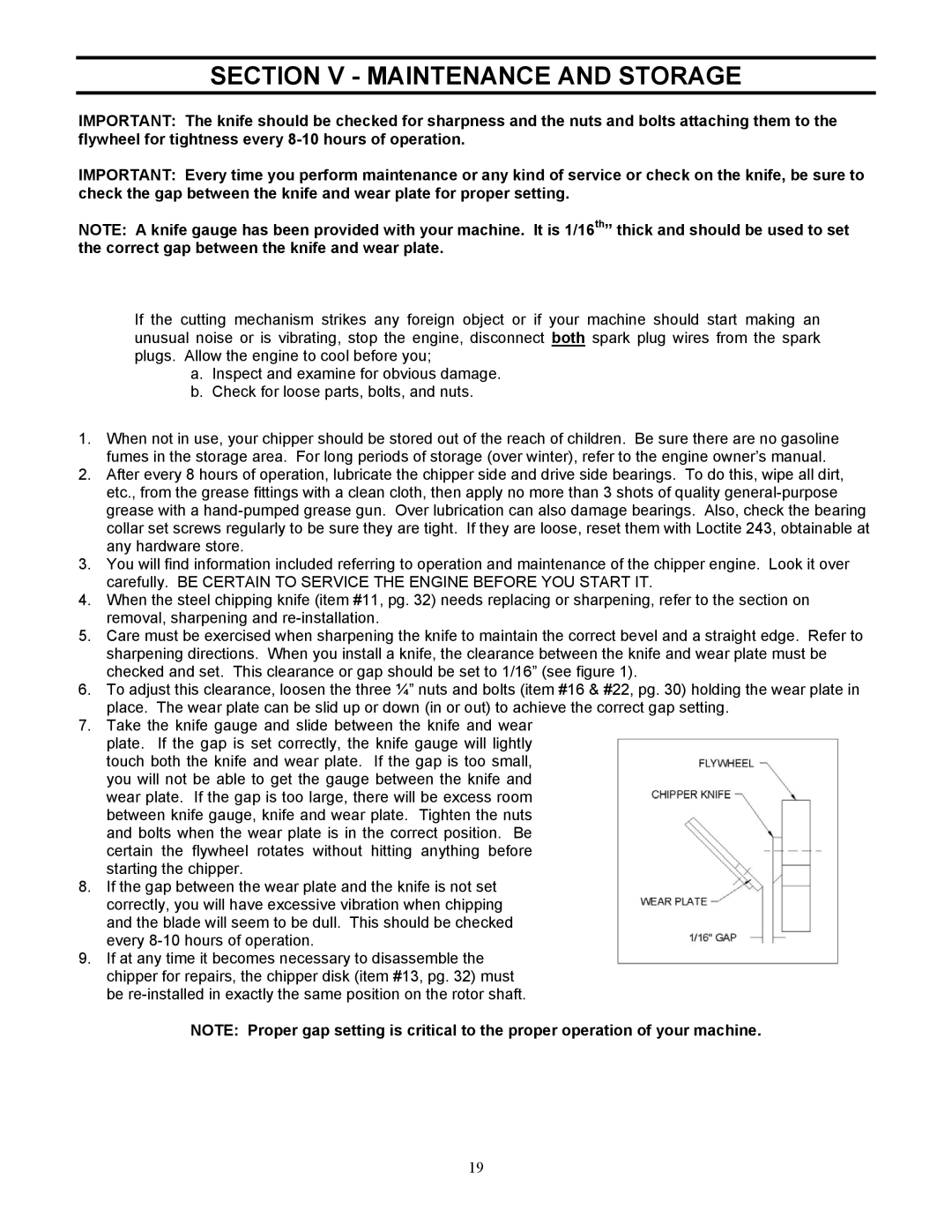

5.Care must be exercised when sharpening the knife to maintain the correct bevel and a straight edge. Refer to sharpening directions. When you install a knife, the clearance between the knife and wear plate must be checked and set. This clearance or gap should be set to 1/16” (see figure 1).

6.To adjust this clearance, loosen the three ¼” nuts and bolts (item #16 & #22, pg. 30) holding the wear plate in place. The wear plate can be slid up or down (in or out) to achieve the correct gap setting.

7.Take the knife gauge and slide between the knife and wear plate. If the gap is set correctly, the knife gauge will lightly touch both the knife and wear plate. If the gap is too small, you will not be able to get the gauge between the knife and wear plate. If the gap is too large, there will be excess room between knife gauge, knife and wear plate. Tighten the nuts and bolts when the wear plate is in the correct position. Be certain the flywheel rotates without hitting anything before starting the chipper.

8.If the gap between the wear plate and the knife is not set correctly, you will have excessive vibration when chipping and the blade will seem to be dull. This should be checked every

9.If at any time it becomes necessary to disassemble the chipper for repairs, the chipper disk (item #13, pg. 32) must be

NOTE: Proper gap setting is critical to the proper operation of your machine.

19