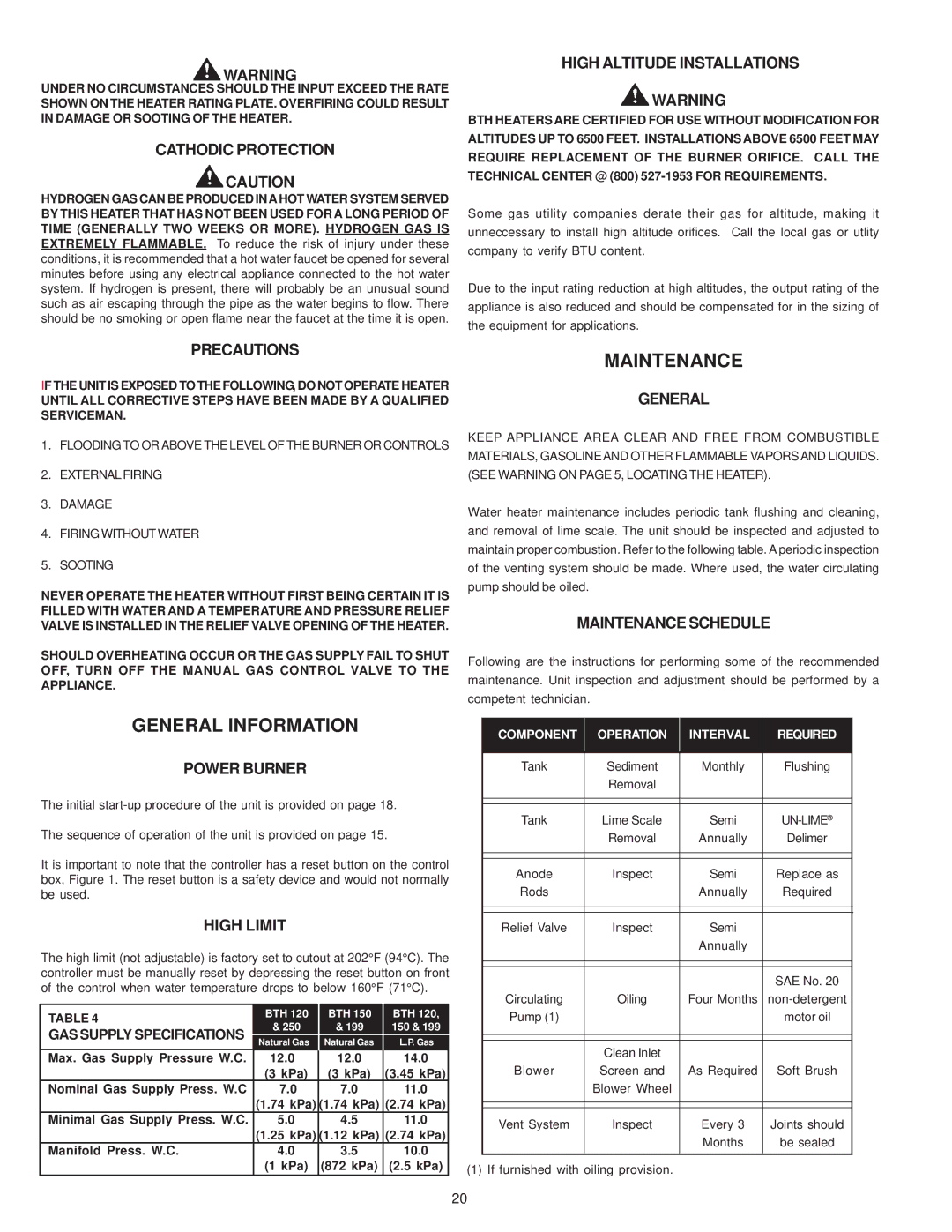

BTH 120-250(A) specifications

A.O. Smith BTH 120-250(A) is a cutting-edge water heater designed to meet the demands of residential and commercial settings. This high-efficiency unit is equipped with a range of features aimed at maximizing performance and minimizing energy consumption, making it a popular choice among homeowners and builders alike.One of the standout features of the A.O. Smith BTH 120-250(A) is its energy efficiency. It operates with a thermal efficiency rating of up to 96%, which means that a significant portion of the fuel consumed is converted into usable hot water. This not only reduces energy bills but also lessens the environmental impact of water heating.

The unit employs advanced condensing technology, which captures and utilizes the heat from flue gases that would otherwise be lost in traditional units. This technology allows for lower exhaust temperatures and the potential for venting through PVC, significantly simplifying installation in various settings.

With a capacity range of 120 to 250 gallons, the BTH series is versatile enough to serve different needs. It is suitable for multiple applications, including large residential homes, commercial businesses, and industrial installations. The varying sizes ensure that it can deliver adequate hot water supply, even during peak demand periods.

In addition to its impressive capacity and efficiency, the A.O. Smith BTH 120-250(A) features a user-friendly digital control system. This allows users to easily set and monitor water temperatures, helping to prevent scalding and ensuring consistent comfort. The integrated diagnostics system alerts users to potential issues, facilitating proactive maintenance and reducing downtime.

Another appealing characteristic of this water heater is its durable construction. Built with high-quality materials, it is designed to withstand the rigors of frequent use while maintaining optimal performance over time. Furthermore, it comes equipped with an innovative flame rollback feature, enhancing safety by reducing the risk of flashback.

Overall, the A.O. Smith BTH 120-250(A) stands out in the competitive water heater market due to its exceptional efficiency, advanced technologies, and robust construction. Whether for residential or commercial use, this model provides reliable hot water supply while promoting energy savings and environmental sustainability. Its combination of performance and user-friendly features makes it a top choice for those seeking a reliable water heating solution.