INSTALLATION INSTRUCTIONS

The expansion tank should have a capacity of at least 7 % of the system's water capacity. The cold water feed pipe should be at least 22mm diameter.

There must not be any shut off valves in the circuit. Pipes should be run to avoid air locks. A spring safety valve should be fitted to the expansion pipe close to the boiler.

It is often possible, and is good practice, to utilise the primary flow and return as part of the safety circuit. The ball valve should have a copper ball. The overflow pipe from the expansion tank should be 28mm diameter copper. Pipes in unheated spaces must be lagged.

FINAL CHECK

Before handing over the installation to the customer it is strongly recommended that the appliance is lit and the functioning of the chimney, hot water and heating system is checked.

A checklist

•Operate the heating system and set the pump head.

•Balance the radiators.

•Check the circulation round the primary system and the heat leak radiator, particularly when the pump is running, to ensure circulation is not reversed.

•Be sure that the chimney is operating and that ALL smoke and fumes are vented to the atmosphere through the chimney terminal.

•Check all joints and seals.

•Clean the outside of the appliance to prevent any stains becoming burnt on.

•Check the flue draught which should read 1 - 2mm, or 0.1 - 0.2mbar.

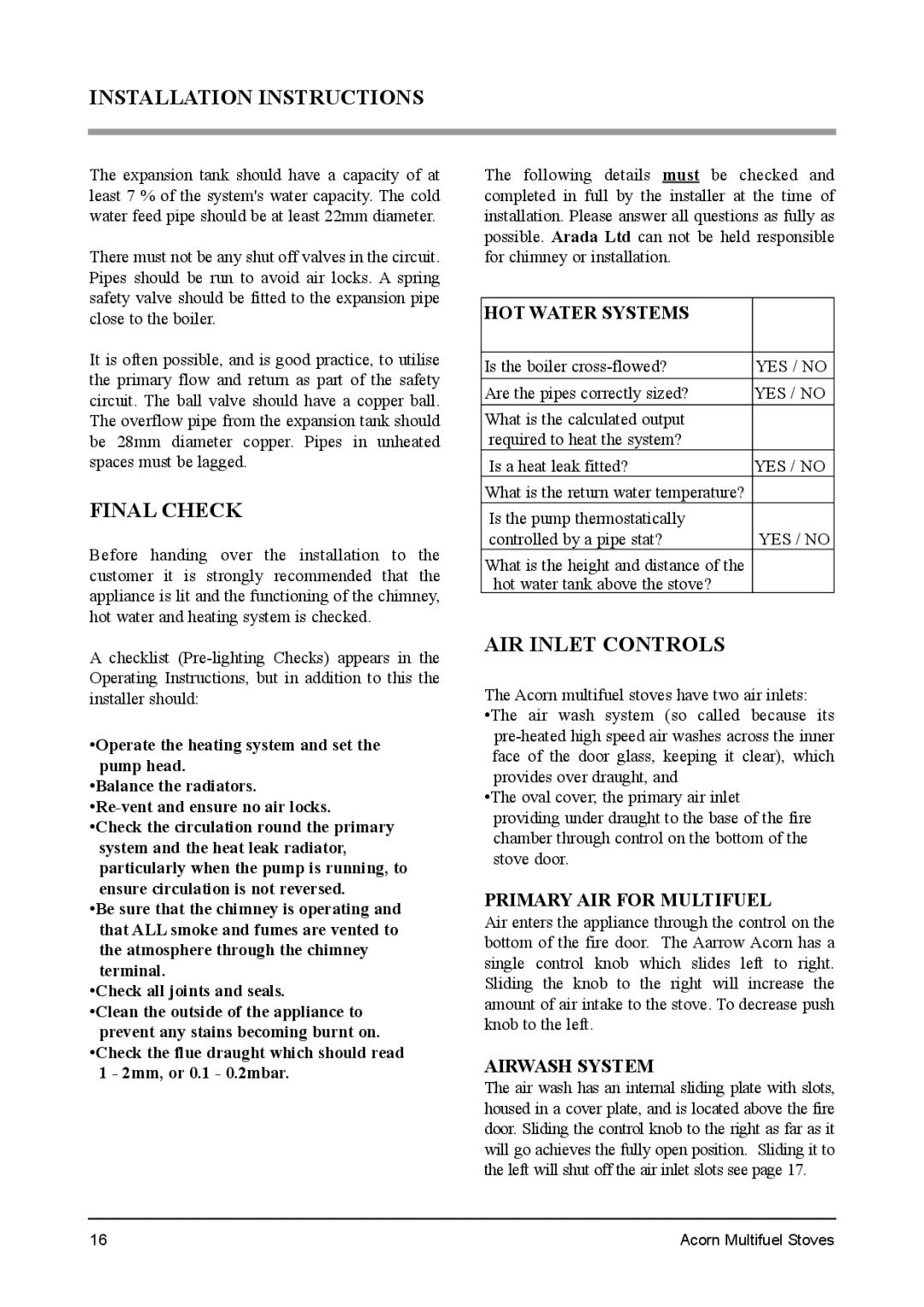

The following details must be checked and completed in full by the installer at the time of installation. Please answer all questions as fully as possible. Arada Ltd can not be held responsible for chimney or installation.

HOT WATER SYSTEMS |

|

|

|

Is the boiler | YES / NO |

Are the pipes correctly sized? | YES / NO |

What is the calculated output |

|

required to heat the system? |

|

Is a heat leak fitted? | YES / NO |

What is the return water temperature? |

|

Is the pump thermostatically |

|

controlled by a pipe stat? | YES / NO |

What is the height and distance of the |

|

hot water tank above the stove? |

|

AIR INLET CONTROLS

The Acorn multifuel stoves have two air inlets: •The air wash system (so called because its

•The oval cover; the primary air inlet providing under draught to the base of the fire chamber through control on the bottom of the stove door.

PRIMARY AIR FOR MULTIFUEL

Air enters the appliance through the control on the bottom of the fire door. The Aarrow Acorn has a single control knob which slides left to right. Sliding the knob to the right will increase the amount of air intake to the stove. To decrease push knob to the left.

AIRWASH SYSTEM

The air wash has an internal sliding plate with slots, housed in a cover plate, and is located above the fire door. Sliding the control knob to the right as far as it will go achieves the fully open position. Sliding it to the left will shut off the air inlet slots see page 17.

16 | Acorn Multifuel Stoves |