INSTALLATION

MULTIFUEL GRATE

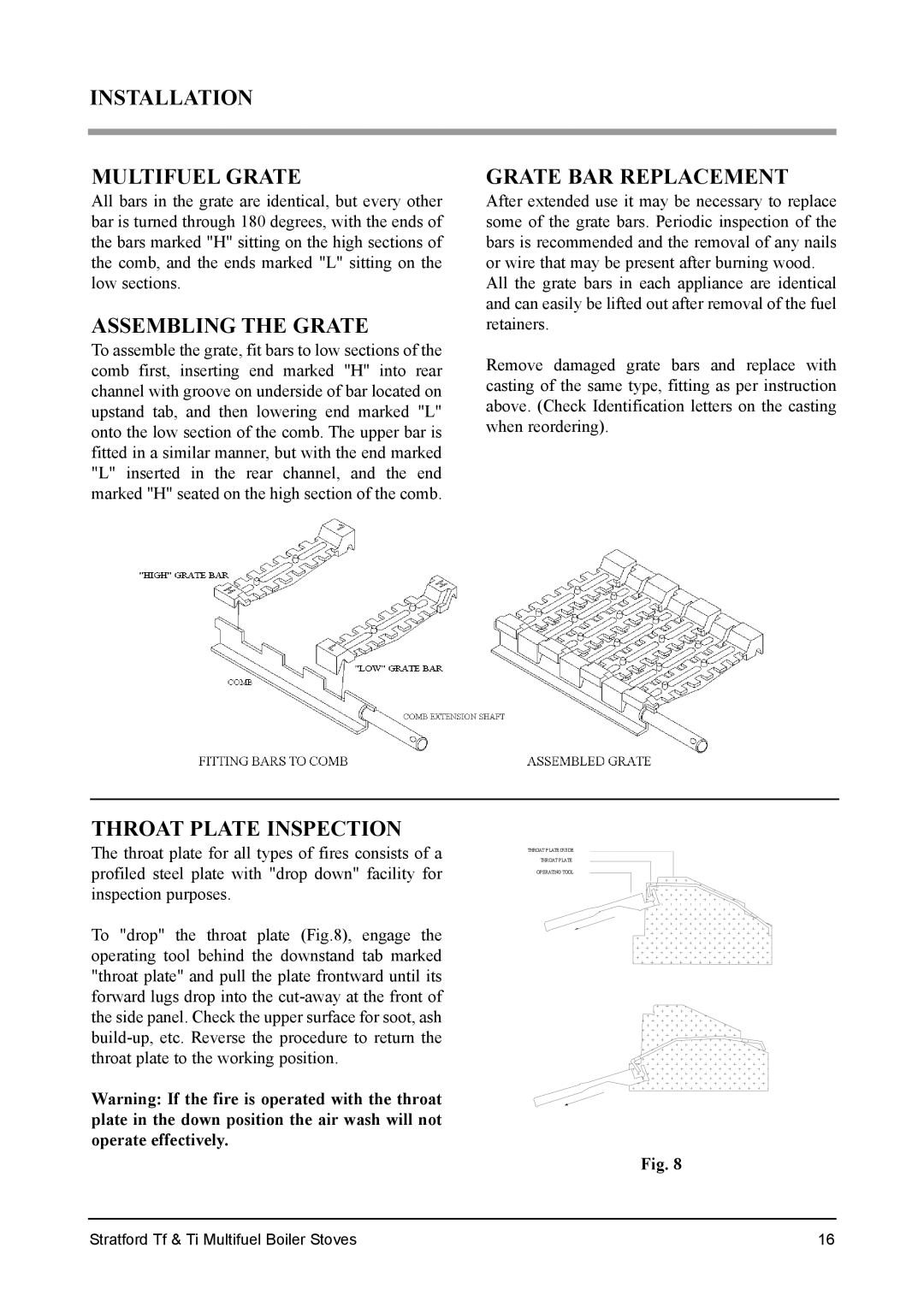

All bars in the grate are identical, but every other bar is turned through 180 degrees, with the ends of the bars marked "H" sitting on the high sections of the comb, and the ends marked "L" sitting on the low sections.

ASSEMBLING THE GRATE

To assemble the grate, fit bars to low sections of the comb first, inserting end marked "H" into rear channel with groove on underside of bar located on upstand tab, and then lowering end marked "L" onto the low section of the comb. The upper bar is fitted in a similar manner, but with the end marked "L" inserted in the rear channel, and the end marked "H" seated on the high section of the comb.

GRATE BAR REPLACEMENT

After extended use it may be necessary to replace some of the grate bars. Periodic inspection of the bars is recommended and the removal of any nails or wire that may be present after burning wood.

All the grate bars in each appliance are identical and can easily be lifted out after removal of the fuel retainers.

Remove damaged grate bars and replace with casting of the same type, fitting as per instruction above. (Check Identification letters on the casting when reordering).

THROAT PLATE INSPECTION

The throat plate for all types of fires consists of a profiled steel plate with "drop down" facility for inspection purposes.

To "drop" the throat plate (Fig.8), engage the operating tool behind the downstand tab marked "throat plate" and pull the plate frontward until its forward lugs drop into the

Warning: If the fire is operated with the throat plate in the down position the air wash will not operate effectively.

THROAT PLATE GUIDE

THROAT PLATE

OPERATING TOOL

Fig. 8

Stratford Tf & Ti Multifuel Boiler Stoves | 16 |