How to Deal with Noise

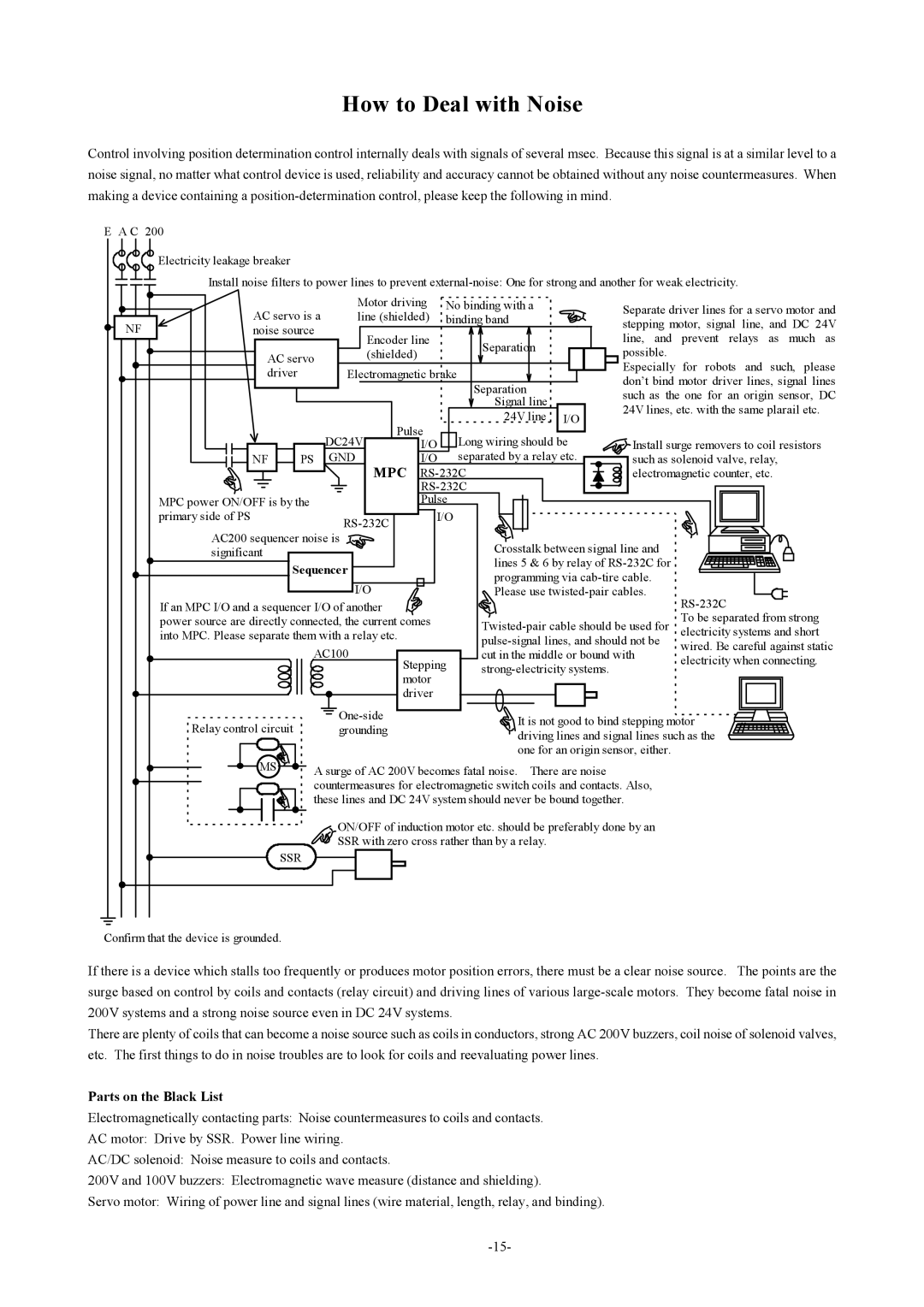

Control involving position determination control internally deals with signals of several msec. Because this signal is at a similar level to a noise signal, no matter what control device is used, reliability and accuracy cannot be obtained without any noise countermeasures. When making a device containing a

E A C 200

Electricity leakage breaker

Install noise filters to power lines to prevent

| AC servo is a | Motor driving | No binding with a |

| Separate driver lines for a servo motor and | ||

| line (shielded) | binding band |

| ||||

NF |

| stepping motor, signal line, and DC 24V | |||||

noise source |

|

|

|

| |||

Encoder line |

|

| line, and prevent relays as much as | ||||

|

|

| Separation |

| |||

| AC servo | (shielded) |

|

| possible. | ||

|

|

|

| ||||

|

|

|

|

| Especially for robots and such, please | ||

| driver |

| Electromagnetic brake |

| |||

|

|

| don’t bind motor driver lines, signal lines | ||||

|

|

|

|

| Separation |

| |

|

|

|

|

|

| such as the one for an origin sensor, DC | |

|

|

|

|

| Signal line |

| |

|

|

|

|

|

| 24V lines, etc. with the same plarail etc. | |

|

|

|

|

| 24V line | I/O | |

|

|

| Pulse |

| |||

|

|

| Long wiring should be |

| |||

|

|

| DC24V | I/O | Install surge removers to coil resistors | ||

| NF | PS | GND | I/O | separated by a relay etc. | such as solenoid valve, relay, | |

|

|

| MPC |

| electromagnetic counter, etc. | ||

|

|

|

|

|

| ||

| MPC power ON/OFF is by the |

| Pulse |

|

| ||

| primary side of PS |

| I/O |

|

| ||

|

|

|

|

|

|

| |

AC200 sequencer noise is | Crosstalk between signal line and |

| ||

significant |

|

| ||

| lines 5 & 6 by relay of |

| ||

Sequencer |

| |||

programming via |

| |||

| I/O |

| ||

| Please use | |||

If an MPC I/O and a sequencer I/O of another |

| |||

power source are directly connected, the current comes |

| To be separated from strong | ||

into MPC. Please separate them with a relay etc. | ||||

wired. Be careful against static | ||||

| AC100 | |||

| cut in the middle or bound with | |||

| electricity when connecting. | |||

| Stepping | |||

|

| |||

| motor |

| ||

|

|

| ||

| driver |

|

| |

Relay control circuit | It is not good to bind stepping motor | |||

grounding | ||||

driving lines and signal lines such as the | ||||

|

| |||

|

| one for an origin sensor, either. |

| |

MS | A surge of AC 200V becomes fatal noise. There are noise |

| ||

|

| |||

| countermeasures for electromagnetic switch coils and contacts. Also, |

| ||

| these lines and DC 24V system should never be bound together. |

| ||

| ON/OFF of induction motor etc. should be preferably done by an |

| ||

| SSR with zero cross rather than by a relay. |

| ||

SSR |

|

|

| |

Confirm that the device is grounded.

If there is a device which stalls too frequently or produces motor position errors, there must be a clear noise source. The points are the surge based on control by coils and contacts (relay circuit) and driving lines of various

There are plenty of coils that can become a noise source such as coils in conductors, strong AC 200V buzzers, coil noise of solenoid valves, etc. The first things to do in noise troubles are to look for coils and reevaluating power lines.

Parts on the Black List

Electromagnetically contacting parts: Noise countermeasures to coils and contacts.

AC motor: Drive by SSR. Power line wiring.

AC/DC solenoid: Noise measure to coils and contacts.

200V and 100V buzzers: Electromagnetic wave measure (distance and shielding).

Servo motor: Wiring of power line and signal lines (wire material, length, relay, and binding).