IMPORTANT INSTRUCTIONS BEFORE INSTALLATION

Failure to follow these instructions may cause serious bodily injury and/or property damage.

Warranty void if product modified, drilled,

!painted, or altered in any way; if used to WARNING pump hot water, or to pump liquids other

than water (such as but not limited to chemi- cals, fertilizers, flammable liquids, herbicides, mud, tar, cement, wood chips); or otherwise abused.

1.Before installing or servicing your pump, BE CER- TAIN pump power source is disconnected.

2.All installation and electrical wiring must adhere to state and local codes and must be complete before priming the pump. Check with appropriate community agencies, or contact your local electrical and pump professionals.

3.Pump should be installed in a dry, convenient location which is close to the well and provides ample space for installation and servicing the well. A dry basement, pit, or utility room is an excellent choice when allowed by law.

4.CALL AN ELECTRICIAN WHEN IN DOUBT. Pump should be connected to a separate electrical circuit directly from main switch. There must be a fuse box or circuit breaker installed in this line. Plugging into exist- ing outlets may cause low voltage at motor, resulting in blown fuses, tripping of motor overload, or burned out motor. Refer to electrical diagrams on following page for electrical connections.

5.It is mandatory that a permanent ground connection be made from the pump to the grounding bar at the service panel. Do not connect pump to a power supply until permanently grounded. For maximum safety, ground the pump to a circuit equipped with a fault interrupter device.

6.Motor Grounding Instructions: WARNING Reduced risk of electric shock during operation of this

pump requires the provision of acceptable grounding.

Caution: Failure to ground this unit properly may result in severe electrical shock. If the means of connection to the

7.Voltage of power supply must match the voltage of the pump which is factory preset to 115V, but may be rewired for 230V (see following page).

8.During installation, cover well to prevent foreign matter from contaminating the well or later damaging the pump during operation. Test well water for purity. Chlorination may be necessary. Check local Health Department for proper testing and recommendations.

9.Hand pump new wells until clear. Sand or other sediment will seriously damage the pump.

10.The

11.The following may cause severe damage to pump and/or piping and will void warranty:

•Failure to protect pump and piping against below freezing temperatures.

•Pumping chemicals or corrosive liquids.

•Running the pump dry. Follow priming instructions on pages 4 or 8, depending on the installation.

•Using extension cords.

•Pumping gasoline or other flammable liquids.

•Using this pump in or near a swimming pool.

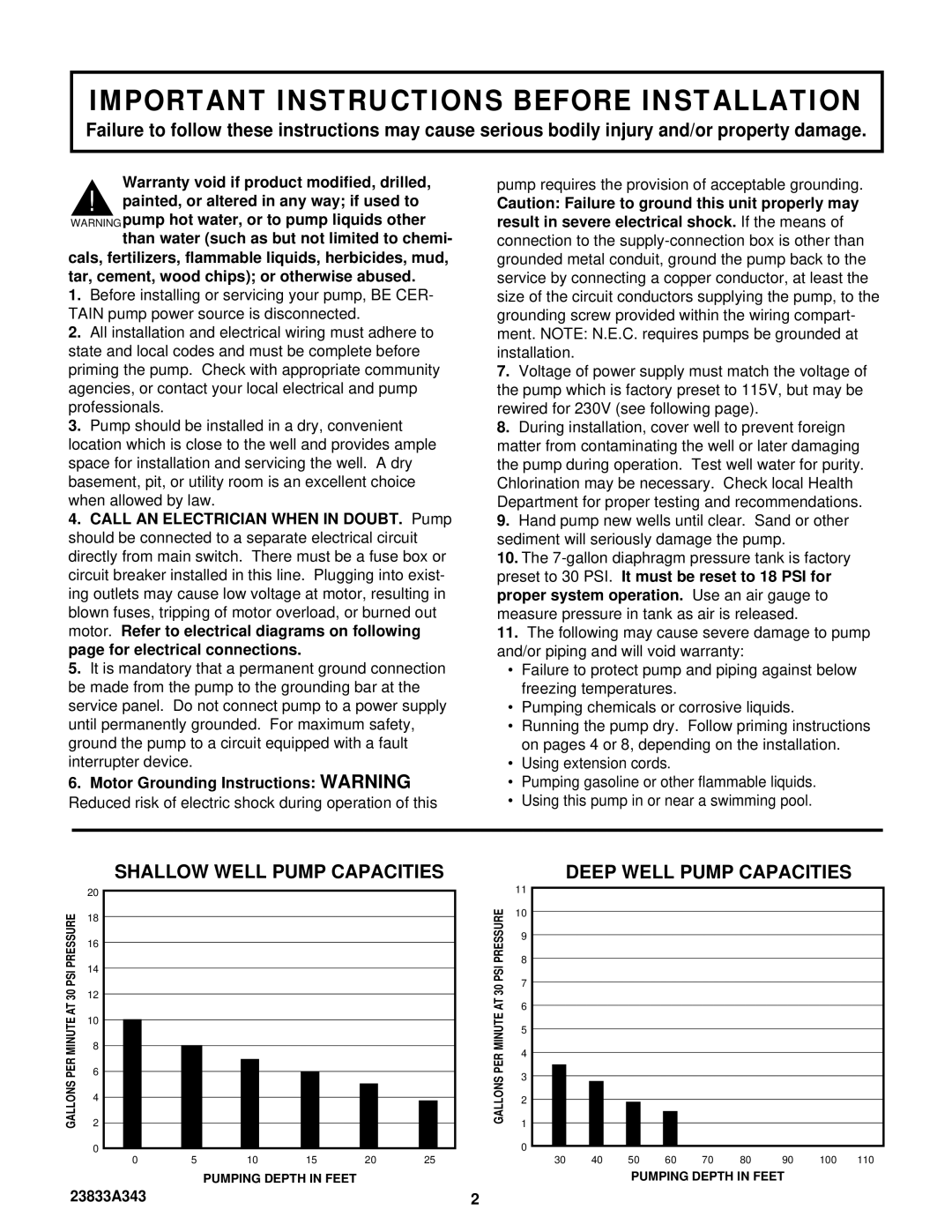

SHALLOW WELL PUMP CAPACITIES

| 20 |

|

|

|

|

|

PRESSURE | 18 |

|

|

|

|

|

16 |

|

|

|

|

| |

14 |

|

|

|

|

| |

30 PSI |

|

|

|

|

| |

12 |

|

|

|

|

| |

AT | 10 |

|

|

|

|

|

PER MINUTE |

|

|

|

|

| |

8 |

|

|

|

|

| |

6 |

|

|

|

|

| |

GALLONS | 4 |

|

|

|

|

|

2 |

|

|

|

|

| |

| 0 |

|

|

|

|

|

| 0 | 5 | 10 | 15 | 20 | 25 |

PUMPING DEPTH IN FEET

GALLONS PER MINUTE AT 30 PSI PRESSURE

DEEP WELL PUMP CAPACITIES

11

10

9

8

7 |

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 |

PUMPING DEPTH IN FEET

23833A343 | 2 |