STEP Remove pipe clamp and 4 slide Well Seal

over PVC pipe and onto well casing. Position assembly

so twelve inches of PVC pipe pro- trude from well seal. Alternately turn bolts on well seal counterclockwise until rubber gaskets are tight against well casing and PVC pipe.

STEP Cement

of PVC pipe before cementing elbow. Smooth inside of any cut PVC pipe with file or knife.

APPROX.

12" OF

PVC PIPE

PROTRUDING FROM WELL SEAL

WELL

SEAL

PVC

ELBOW

TOP OF

PVC PIPE

PROTRUDING FROM WELL SEAL

STEP 9 maximum water flow is obtained without CONT'D pressure dropping to zero. If pressure falls

completely, retighten adjustment screw and

than 24 lbs. for the R520. If no pressure shows:

Stop motor, remove pressure gauge plug from pressure regulator, add more water, and try again.

STEP Thread pressure gauge plug back

10 into discharge tee. Thread

pressure gauge into pres- sure gauge plug. Make sure all connections are tightly sealed. Place a large basin beneath dia- phragm tank outlet. Start

STEP Open ejector |

| VENTURI |

| |

6 | pack included | GASKET | TUBE | BOLTS |

|

| EJECTOR | ||

with your jet sys- |

|

|

| |

tem. The ejector |

|

|

| |

|

|

|

| |

has two holes in its top. |

|

|

| |

Thread the venturi tube |

|

|

| |

|

|

| ||

(part #25881A281 stamped on the side) into larger hole until snug. Put gasket over venturi tube so openings in gasket line up with openings in ejector.

STEP Secure ejector and |

| |

7 | gasket to front of tank- | EJECTOR |

| ||

| mounted pump with | |

|

| |

| bolts provided. Thread | MALE PVC |

| a | ADAPTER |

|

| |

| adapter into front of |

|

| ejector. |

|

STEP Cement as much PVC pipe and couplings 8 needed to connect PVC elbow to male PVC

adapter in front of ejector. The diaphragm pressure tank is preset to 30 PSI. Reset

pressure to 18 PSI using a tire gauge. This is vital to proper operation of the system.

motor. If pump is

from well 4 feet or more, it may take a few minutes

for pump to prime. Failure to prime in 5 minutes: Stop motor, remove pressure gauge plug from dis- charge tee, add more water, try again. Allow pump to run long enough to clear the well of sand or dirt and to insure well will not run dry. Stop motor.

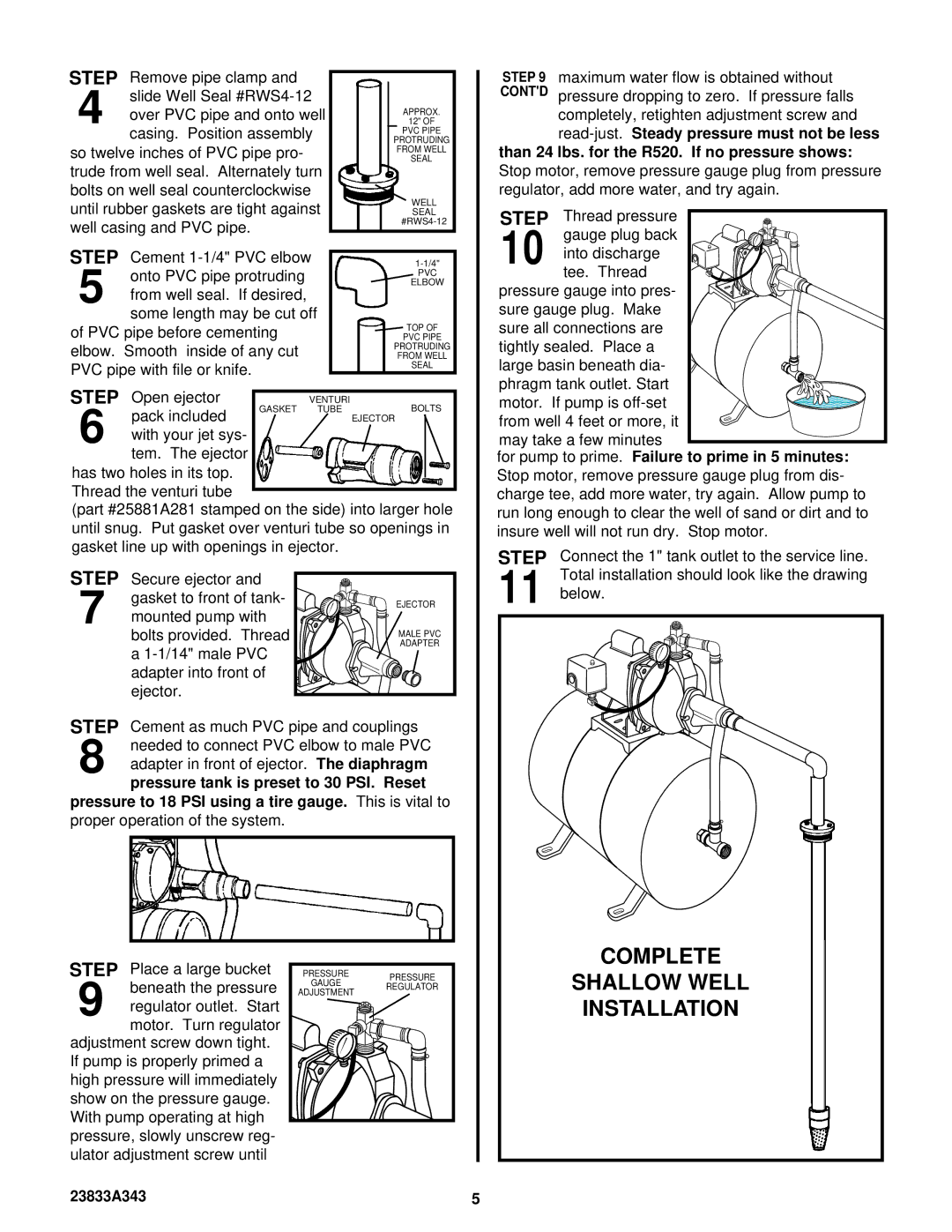

STEP Connect the 1" tank outlet to the service line. Total installation should look like the drawing

11 below.

STEP Place a large bucket beneath the pressure

9 regulator outlet. Start motor. Turn regulator

adjustment screw down tight. If pump is properly primed a high pressure will immediately show on the pressure gauge. With pump operating at high pressure, slowly unscrew reg- ulator adjustment screw until

PRESSURE PRESSURE

GAUGE REGULATOR ADJUSTMENT

COMPLETE

SHALLOW WELL

INSTALLATION

23833A343 | 5 |