PIPING

Plastic PVC pipe is shown in the illustrations, but galvanized steel pipe may be used if desired. All piping must be clean and free of all foreign matter to prevent clogging. ALL JOINTS AND CONNECTIONS IN THE WELL ASSEMBLY MUST BE AIRTIGHT. Even a pin- hole leak will prevent the proper operation of the pump (this is the most common problem). Use thread com- pound on all threaded joints unless specified otherwise.

DRAINING FOR SERVICING OR FOR WINTER

The pump should be drained before it is disconnected for servicing or if it is in danger of freezing. To drain:

•Remove drain plug from bottom of pump case.

•Remove discharge tee to vent the pump.

•Drain all piping to a point 3 feet below ground level.

SHALLOW WELL PUMP INSTALLATION (4" DIAMETER CASED WELL)

For wells 25 feet or less in depth, the ejector may be attached to the front of the

General Materials

•One Jet Tank System

•One can PVC cement (read instructions carefully)

•One can thread compound (read instructions carefully)

•Two male

•Enough rigid

•One 4" well seal

•One

Tools Needed for all pump installations

Pipe wrench, pipe clamp, crescent wrench, slot screw- driver,

REMINDER: ALL JOINTS AND CONNECTIONS MUST BE AIRTIGHT. A SINGLE PIN- HOLE LEAK WILL PREVENT THE PROPER OPERATION OF THE PUMP. USE THREAD COMPOUND ON ALL THREADED CONNECTIONS UNLESS SPECIFIED OTHERWISE.

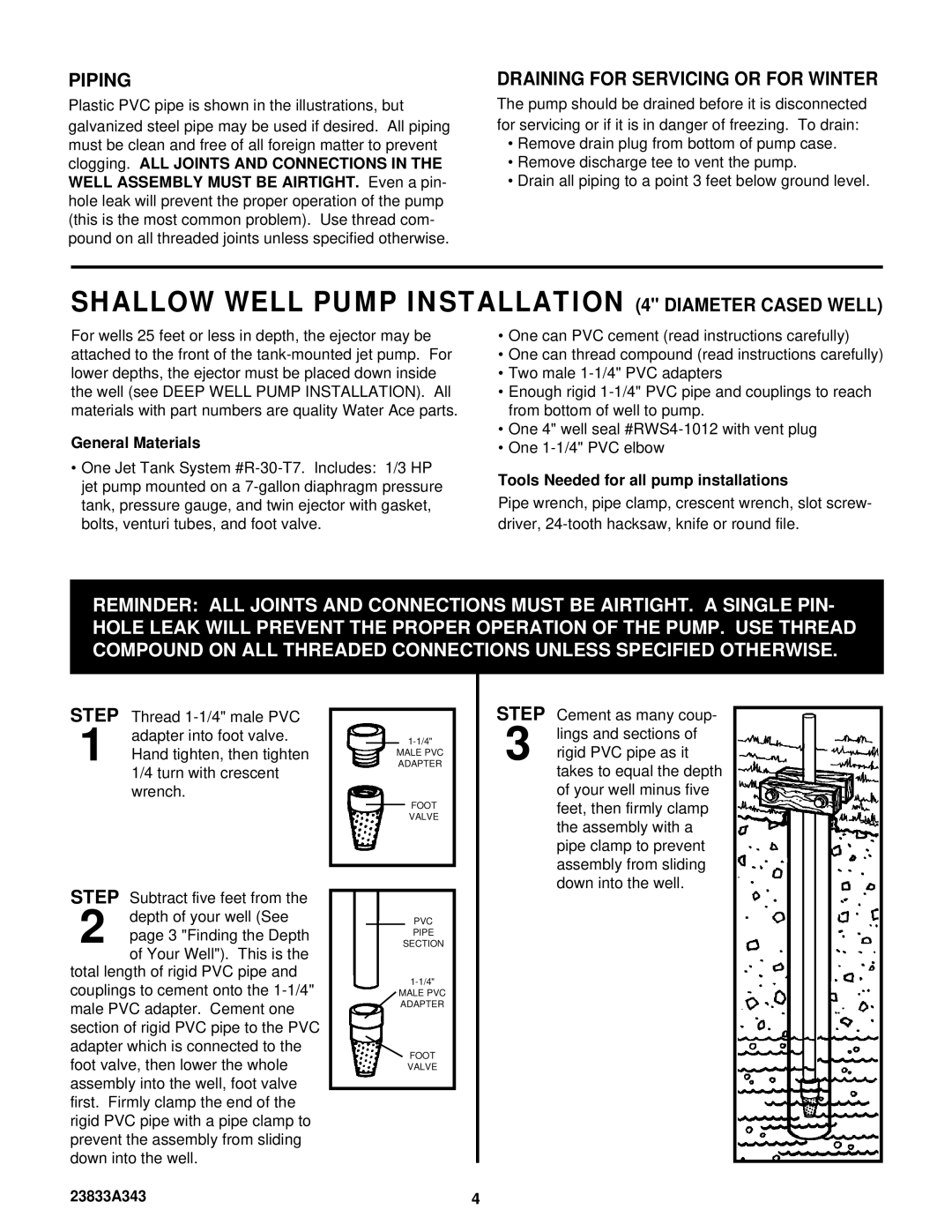

STEP Thread

Hand tighten, then tighten 1/4 turn with crescent wrench.

STEP Subtract five feet from the 2 depth of your well (See

page 3 "Finding the Depth of Your Well"). This is the

total length of rigid PVC pipe and couplings to cement onto the

MALE PVC ADAPTER

FOOT

VALVE

PVC

PIPE

SECTION

MALE PVC ADAPTER

FOOT

VALVE

STEP Cement as many coup- 3 lings and sections of

rigid PVC pipe as it takes to equal the depth of your well minus five feet, then firmly clamp the assembly with a pipe clamp to prevent assembly from sliding down into the well.

23833A343

4