NOTE:

*1. The display can not happen flicker or shutdown.

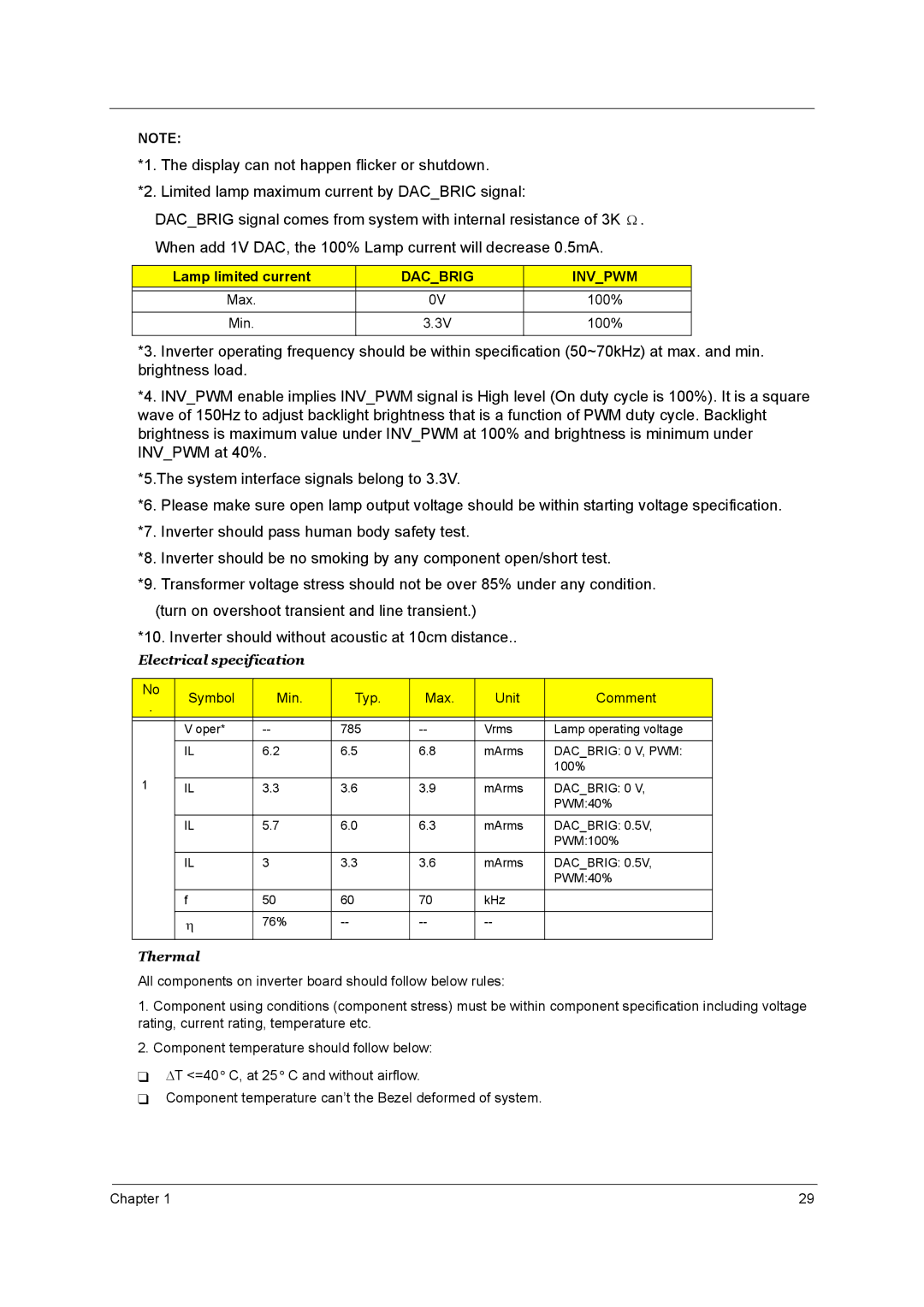

*2. Limited lamp maximum current by DAC_BRIC signal:

DAC_BRIG signal comes from system with internal resistance of 3K Ω .

When add 1V DAC, the 100% Lamp current will decrease 0.5mA.

Lamp limited current | DAC_BRIG | INV_PWM |

|

|

|

Max. | 0V | 100% |

Min. | 3.3V | 100% |

|

|

|

*3. Inverter operating frequency should be within specification (50~70kHz) at max. and min. brightness load.

*4. INV_PWM enable implies INV_PWM signal is High level (On duty cycle is 100%). It is a square wave of 150Hz to adjust backlight brightness that is a function of PWM duty cycle. Backlight brightness is maximum value under INV_PWM at 100% and brightness is minimum under INV_PWM at 40%.

*5.The system interface signals belong to 3.3V.

*6. Please make sure open lamp output voltage should be within starting voltage specification.

*7. Inverter should pass human body safety test.

*8. Inverter should be no smoking by any component open/short test.

*9. Transformer voltage stress should not be over 85% under any condition. (turn on overshoot transient and line transient.)

*10. Inverter should without acoustic at 10cm distance..

Electrical specification

No | Symbol | Min. | Typ. | Max. | Unit | Comment | |

. | |||||||

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

| V oper* | 785 | Vrms | Lamp operating voltage | |||

|

|

|

|

|

|

| |

| IL | 6.2 | 6.5 | 6.8 | mArms | DAC_BRIG: 0 V, PWM: | |

|

|

|

|

|

| 100% | |

1 |

|

|

|

|

|

| |

IL | 3.3 | 3.6 | 3.9 | mArms | DAC_BRIG: 0 V, | ||

|

|

|

|

|

| PWM:40% | |

|

|

|

|

|

|

| |

| IL | 5.7 | 6.0 | 6.3 | mArms | DAC_BRIG: 0.5V, | |

|

|

|

|

|

| PWM:100% | |

|

|

|

|

|

|

| |

| IL | 3 | 3.3 | 3.6 | mArms | DAC_BRIG: 0.5V, | |

|

|

|

|

|

| PWM:40% | |

|

|

|

|

|

|

| |

| f | 50 | 60 | 70 | kHz |

| |

|

|

|

|

|

|

| |

| η | 76% |

| ||||

|

|

|

|

|

|

|

Thermal

All components on inverter board should follow below rules:

1.Component using conditions (component stress) must be within component specification including voltage rating, current rating, temperature etc.

2.Component temperature should follow below:

∆T <=40° C, at 25° C and without airflow.

Component temperature can’t the Bezel deformed of system.

Chapter 1 | 29 |