K. PREOPERATIONAL INSTRUCTIONS

NON-COIN MODELS

1.To start the dryer:

a.Microprocessor Controller (Computer) Dryers...

1)The light emitting diode (L.E.D.) display will read “READY.”

2)Press the “E” on the keypad.

3)The dryer will start, and the L.E.D. display will show “MANUAL DRYING CYCLE E, DRYING TEMPERATURE 180º F, DRYING TIME 50 MINUTES.”

b.Dual Timer Dryers...

1)Turn drying timer knob for a time of 20 minutes.

2)Select “High Temp.”

3)Push “Push To Start” button.

4)To stop dryer, open the main door.

2.Spin and dwell (stop) times are adjustable at the reversing timer.

L.COMPRESSED AIR REQUIREMENTS

The dryer requires an external supply of compressed air (2.5 cfh [cubic feet per hour] @ 80 psi [0.07 cmh [cubic meters per hour] @ 5.51 bar] for gas models and 3.25 cfh @ 80 psi [0.09 cmh @ 5.51 bar] for steam models). For steam models, compressed air is necessary for the air operated steam damper. On both the steam models as well as the gas models, compressed air is necessary/required for blower air jet operation...to clean lint from the impellor/fan (squirrel cage).

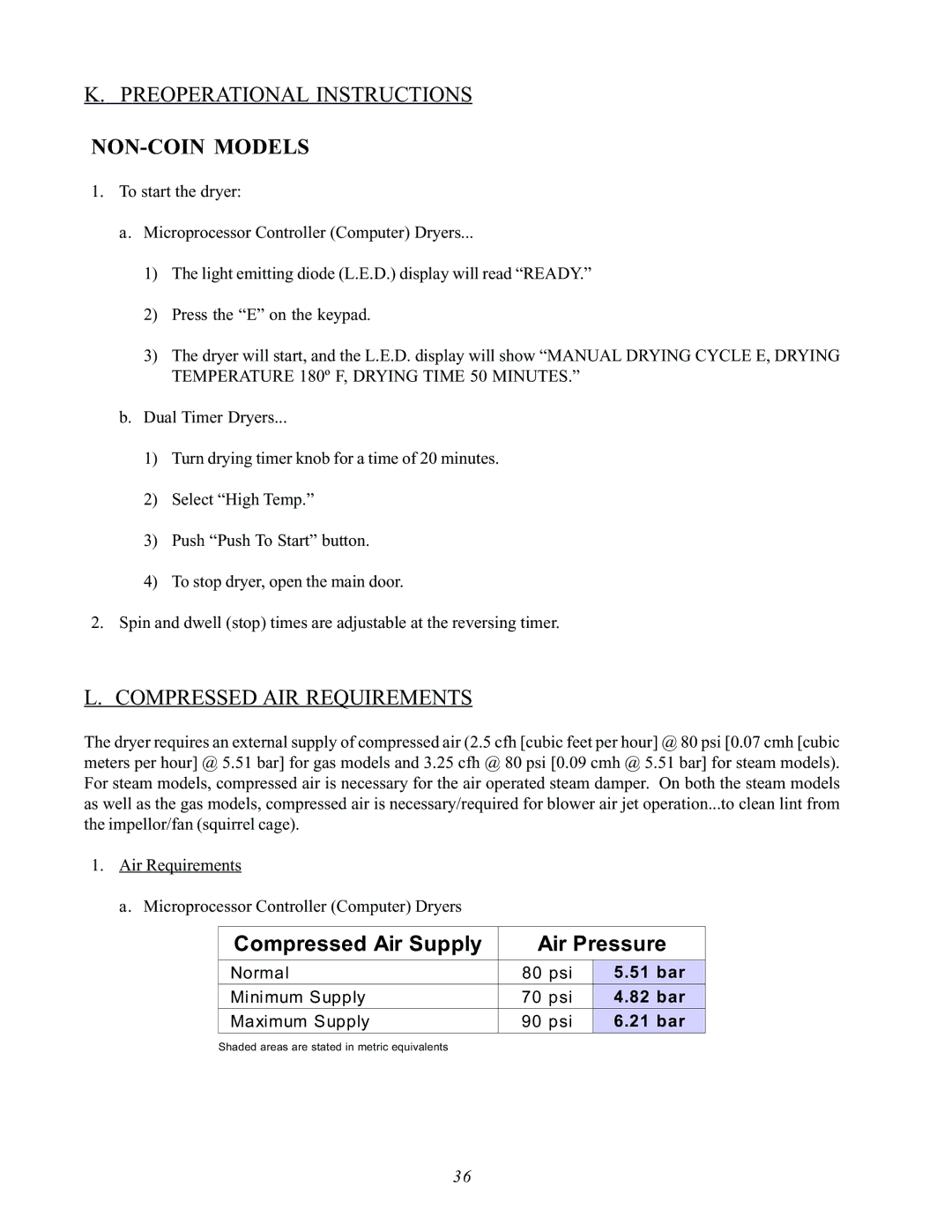

1. Air Requirements

a. Microprocessor Controller (Computer) Dryers

Compressed Air Supply | Air Pressure | ||

|

|

|

|

Normal | 80 psi | 5.51 | bar |

Minimum Supply | 70 psi | 4.82 | bar |

Maximum Supply | 90 psi | 6.21 | bar |

Shaded areas are stated in metric equivalents

36