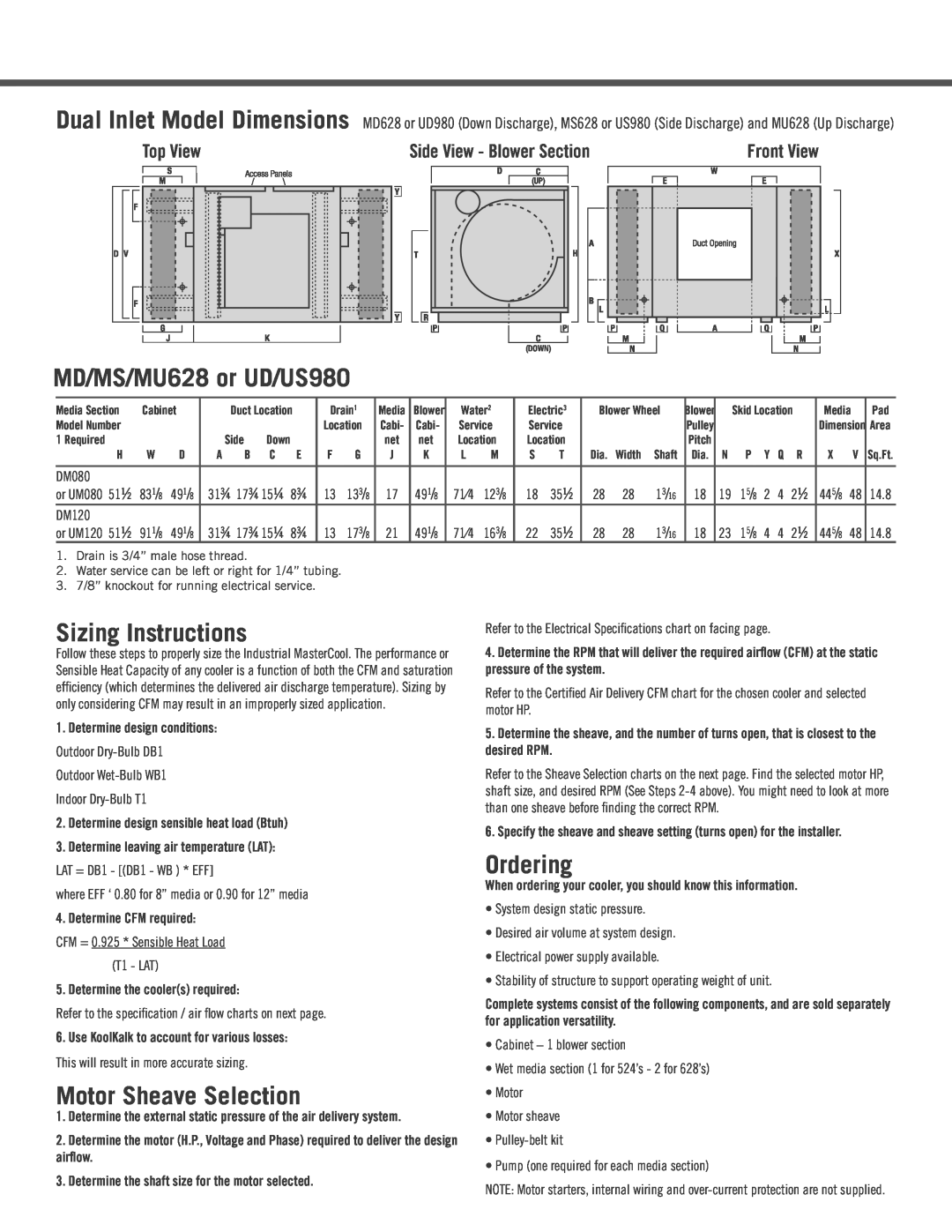

Dual Inlet Model Dimensions MD628 or UD980 (Down Discharge), MS628 or US980 (Side Discharge) and MU628 (Up Discharge)

Top View |

|

| Side View - Blower Section | Front View | ||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (UP) |

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(DOWN)

MD/MS/MU628 or UD/US980

Media Section | Cabinet | Duct Location |

| Drain1 | Media | Blower | Water2 | Electric3 | Blower Wheel | Blower |

| Skid Location | Media | Pad | ||||||||||||

Model Number |

|

|

|

|

|

| Location | Cabi- | Cabi- | Service | Service |

|

|

| Pulley |

|

|

|

|

| Dimension | Area | ||||

1 Required |

|

| Side |

| Down |

|

|

| net | net | Location | Location |

|

|

| Pitch |

|

|

|

|

|

|

|

| ||

H | W | D | A | B | C | E | F | G | J | K | L | M | S | T | Dia. | Width | Shaft | Dia. | N | P | Y | Q | R | X | V | Sq.Ft. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DM080 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or UM080 51½ | 831/8 | 491/8 | 31¾ 17¾ 15¼ 8¾ | 13 | 133/8 | 17 | 491/8 | 71⁄4 | 123/8 | 18 | 35½ | 28 | 28 | 13/16 | 18 | 19 | 15/8 | 2 | 4 | 2½ | 445/8 | 48 | 14.8 | |||

DM120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or UM120 51½ | 911/8 | 491/8 | 31¾ 17¾ 15¼ 8¾ | 13 | 173/8 | 21 | 491/8 | 71⁄4 | 163/8 | 22 | 35½ | 28 | 28 | 13/16 | 18 | 23 | 15/8 | 4 | 4 | 2½ | 445/8 | 48 | 14.8 | |||

1.Drain is 3/4” male hose thread.

2.Water service can be left or right for 1/4” tubing.

3.7/8” knockout for running electrical service.

Sizing Instructions

Follow these steps to properly size the Industrial MasterCool. The performance or Sensible Heat Capacity of any cooler is a function of both the CFM and saturation efficiency (which determines the delivered air discharge temperature). Sizing by only considering CFM may result in an improperly sized application.

1. Determine design conditions:

Outdoor

Outdoor

Indoor

2.Determine design sensible heat load (Btuh)

3.Determine leaving air temperature (LAT):

LAT = DB1 - [(DB1 - WB ) * EFF]

where EFF ‘ 0.80 for 8” media or 0.90 for 12” media

4. Determine CFM required:

CFM = 0.925 * Sensible Heat Load

(T1 - LAT)

5. Determine the cooler(s) required:

Refer to the specification / air flow charts on next page.

6. Use KoolKalk to account for various losses:

This will result in more accurate sizing.

Motor Sheave Selection

1.Determine the external static pressure of the air delivery system.

2.Determine the motor (H.P., Voltage and Phase) required to deliver the design airflow.

3.Determine the shaft size for the motor selected.

Refer to the Electrical Specifications chart on facing page.

4.Determine the RPM that will deliver the required airflow (CFM) at the static pressure of the system.

Refer to the Certified Air Delivery CFM chart for the chosen cooler and selected motor HP.

5.Determine the sheave, and the number of turns open, that is closest to the desired RPM.

Refer to the Sheave Selection charts on the next page. Find the selected motor HP, shaft size, and desired RPM (See Steps

6. Specify the sheave and sheave setting (turns open) for the installer.

Ordering

When ordering your cooler, you should know this information.

•System design static pressure.

•Desired air volume at system design.

•Electrical power supply available.

•Stability of structure to support operating weight of unit.

Complete systems consist of the following components, and are sold separately for application versatility.

•Cabinet – 1 blower section

•Wet media section (1 for 524’s - 2 for 628’s)

•Motor

•Motor sheave

•

•Pump (one required for each media section)

NOTE: Motor starters, internal wiring and