SINGLE-STAGE INDUSTRIAL EVAPORATIVE COOLING

Direct Evaporative Cooling Process

Direct evaporative cooling exchanges sensible heat for latent heat, and follows upward along a constant

Chart. The result is a

temperature of

the leaving air

(B) approaching

the

entering air (A).

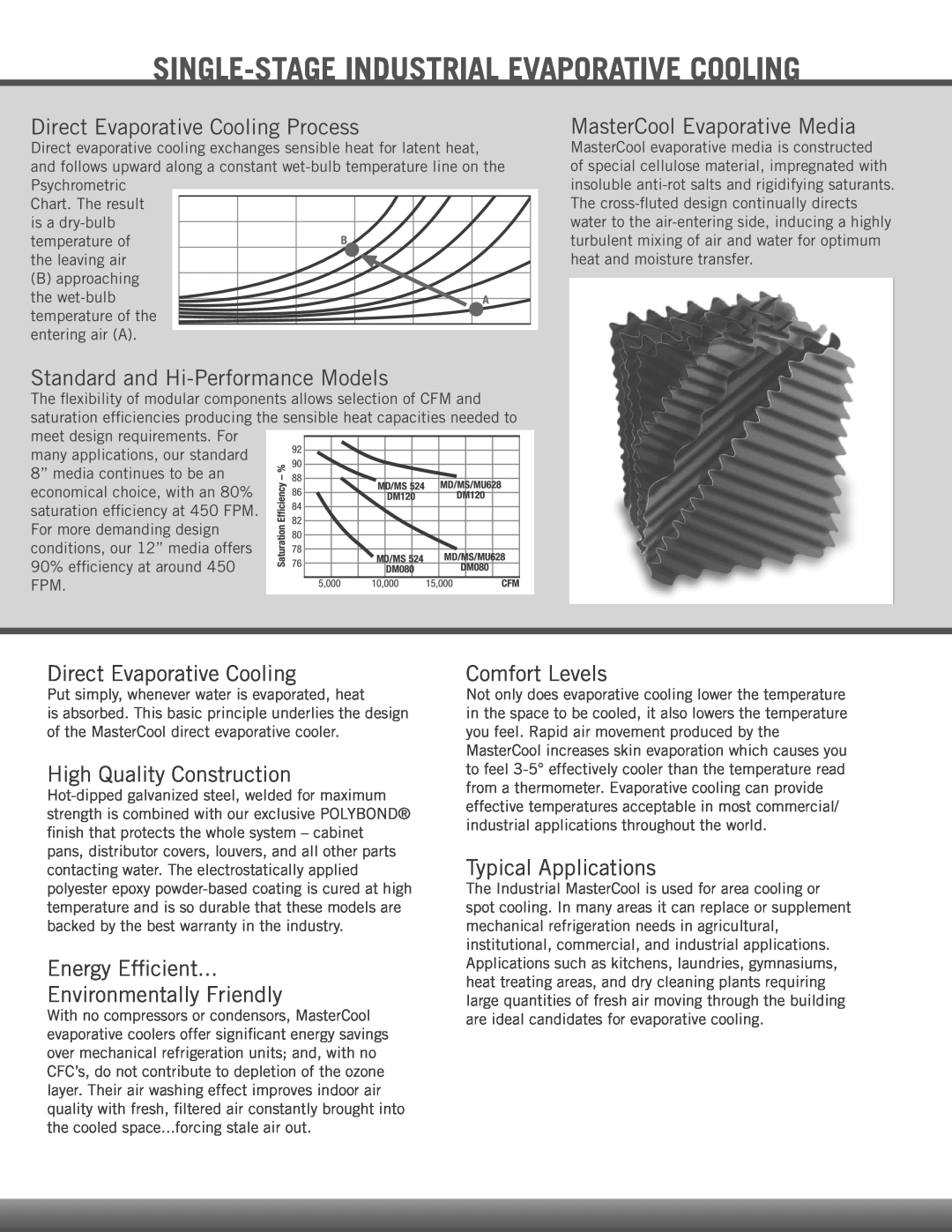

Standard and Hi-Performance Models

The flexibility of modular components allows selection of CFM and saturation efficiencies producing the sensible heat capacities needed to meet design requirements. For

many applications, our standard 8” media continues to be an economical choice, with an 80% saturation efficiency at 450 FPM. For more demanding design

conditions, our 12” media offers 90% efficiency at around 450 FPM.

MasterCool Evaporative Media

MasterCool evaporative media is constructed of special cellulose material, impregnated with insoluble

Direct Evaporative Cooling

Put simply, whenever water is evaporated, heat

is absorbed. This basic principle underlies the design of the MasterCool direct evaporative cooler.

High Quality Construction

Energy Efficient...

Environmentally Friendly

With no compressors or condensors, MasterCool evaporative coolers offer significant energy savings over mechanical refrigeration units; and, with no CFC’s, do not contribute to depletion of the ozone layer. Their air washing effect improves indoor air quality with fresh, filtered air constantly brought into the cooled space...forcing stale air out.

Comfort Levels

Not only does evaporative cooling lower the temperature in the space to be cooled, it also lowers the temperature you feel. Rapid air movement produced by the MasterCool increases skin evaporation which causes you to feel

Typical Applications

The Industrial MasterCool is used for area cooling or spot cooling. In many areas it can replace or supplement mechanical refrigeration needs in agricultural, institutional, commercial, and industrial applications. Applications such as kitchens, laundries, gymnasiums, heat treating areas, and dry cleaning plants requiring large quantities of fresh air moving through the building are ideal candidates for evaporative cooling.