Known devices called calibration standards provide the measurement reference for net- work analyzer

The 8510 network analyzer system has the capability to make

Agilent Technologies supplies full calibration kits in

The 8510’s

The scope of this product note includes a general description of the capabilities of the 8510 to accept new cal kit descriptions via the MODIFY CAL KIT function found in the 8510 CAL menu. It does not, however, describe how to design a set of physical standards. The selection and fabrication of appropriate calibration standards is as var- ied as the transmission media of the partic- ular application and is beyond the scope of this note.

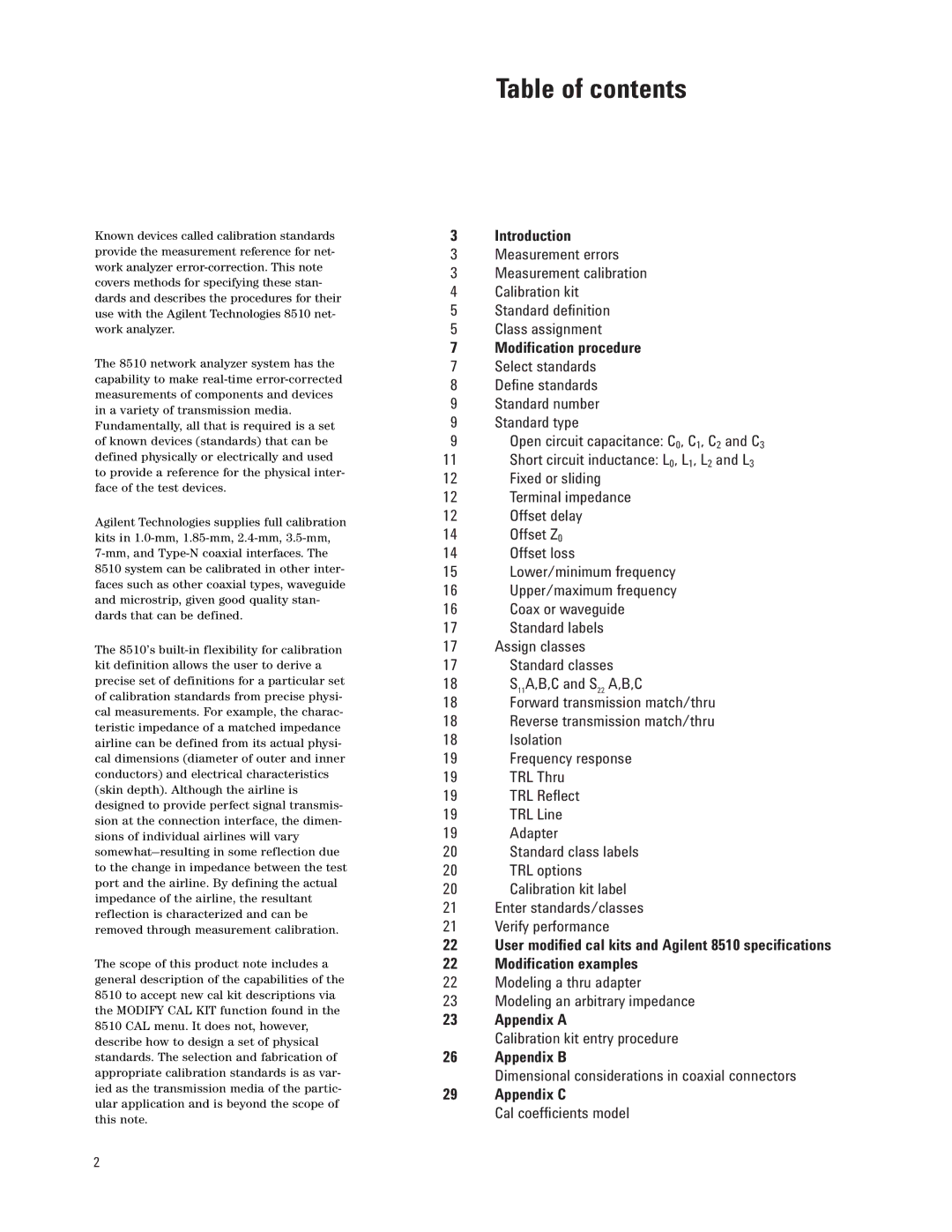

Table of contents

3 | Introduction |

3 | Measurement errors |

3Measurement calibration

4Calibration kit

5Standard definition

5 Class assignment

7Modification procedure

7Select standards

8Define standards

9Standard number

9 | Standard type |

9 | Open circuit capacitance: C0, C1, C2 and C3 |

11Short circuit inductance: L0, L1, L2 and L3

12Fixed or sliding

12 | Terminal impedance |

12 | Offset delay |

14 | Offset Z0 |

14Offset loss

15Lower/minimum frequency

16Upper/maximum frequency

16Coax or waveguide

17Standard labels

17Assign classes

17Standard classes

18S11A,B,C and S22 A,B,C

18 | Forward transmission match/thru |

18 | Reverse transmission match/thru |

18Isolation

19Frequency response

19 | TRL Thru |

19 | TRL Reflect |

19 | TRL Line |

19Adapter

20Standard class labels

20 | TRL options |

20Calibration kit label

21Enter standards/classes

21Verify performance

22User modified cal kits and Agilent 8510 specifications

22Modification examples

22Modeling a thru adapter

23Modeling an arbitrary impedance

23 Appendix A

Calibration kit entry procedure

26Appendix B

Dimensional considerations in coaxial connectors

29Appendix C

Cal coefficients model

2