Introduction

This product note covers measurement calibration requirements for the Agilent 8510B/C network analyzer. All of the capabilities described in this note also apply to the Agilent 8510A with the following exceptions: response & isolation calibra- tion; short circuit inductance; class assignments for forward/reverse isolation, TRL thru, reflect, line and options; and adapter removal.

Measurement errors

Measurement errors in network analysis can be separated into two categories: random and system- atic errors. Both random and systematic errors are vector quantities. Random errors are

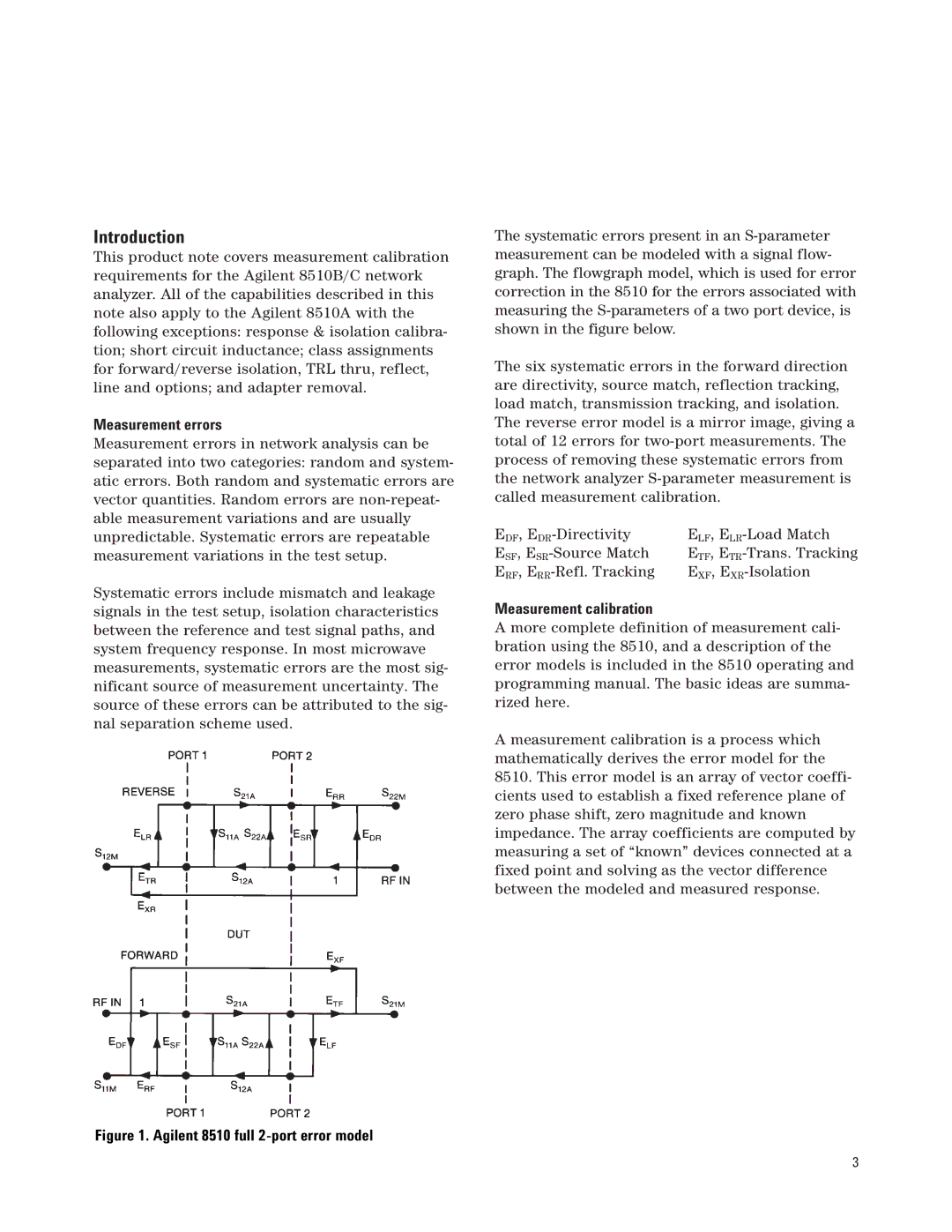

Systematic errors include mismatch and leakage signals in the test setup, isolation characteristics between the reference and test signal paths, and system frequency response. In most microwave measurements, systematic errors are the most sig- nificant source of measurement uncertainty. The source of these errors can be attributed to the sig- nal separation scheme used.

Figure 1. Agilent 8510 full 2-port error model

The systematic errors present in an

The six systematic errors in the forward direction are directivity, source match, reflection tracking, load match, transmission tracking, and isolation. The reverse error model is a mirror image, giving a total of 12 errors for

EDF, | ELF, |

ESF, | ETF, |

ERF, | EXF, |

Measurement calibration

A more complete definition of measurement cali- bration using the 8510, and a description of the error models is included in the 8510 operating and programming manual. The basic ideas are summa- rized here.

A measurement calibration is a process which mathematically derives the error model for the 8510. This error model is an array of vector coeffi- cients used to establish a fixed reference plane of zero phase shift, zero magnitude and known impedance. The array coefficients are computed by measuring a set of “known” devices connected at a fixed point and solving as the vector difference between the modeled and measured response.

3