ASSEMBLY

5.Attach the curb lift cylinder to the carriage and subframe lug with the clevis pins and cotterpins. NOTE: Cylinder rod end attaches to the subframe lug.

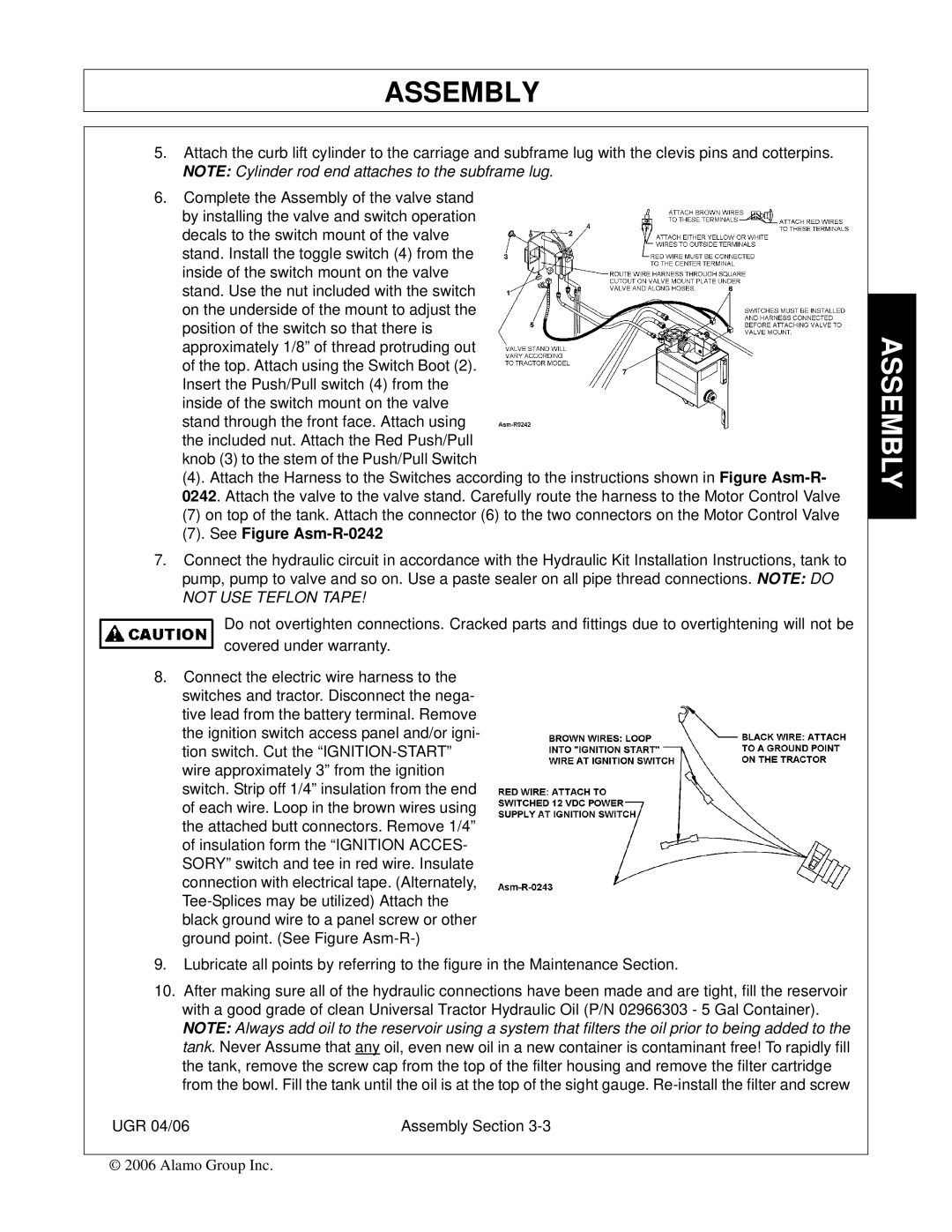

6.Complete the Assembly of the valve stand

by installing the valve and switch operation decals to the switch mount of the valve stand. Install the toggle switch (4) from the inside of the switch mount on the valve stand. Use the nut included with the switch on the underside of the mount to adjust the position of the switch so that there is approximately 1/8” of thread protruding out of the top. Attach using the Switch Boot (2). Insert the Push/Pull switch (4) from the inside of the switch mount on the valve stand through the front face. Attach using the included nut. Attach the Red Push/Pull knob (3) to the stem of the Push/Pull Switch

(4). Attach the Harness to the Switches according to the instructions shown in Figure

(7)on top of the tank. Attach the connector (6) to the two connectors on the Motor Control Valve

(7).See Figure Asm-R-0242

7.Connect the hydraulic circuit in accordance with the Hydraulic Kit Installation Instructions, tank to pump, pump to valve and so on. Use a paste sealer on all pipe thread connections. NOTE: DO NOT USE TEFLON TAPE!

Do not overtighten connections. Cracked parts and fittings due to overtightening will not be covered under warranty.

8.Connect the electric wire harness to the switches and tractor. Disconnect the nega- tive lead from the battery terminal. Remove the ignition switch access panel and/or igni- tion switch. Cut the

9.Lubricate all points by referring to the figure in the Maintenance Section.

10.After making sure all of the hydraulic connections have been made and are tight, fill the reservoir with a good grade of clean Universal Tractor Hydraulic Oil (P/N 02966303 - 5 Gal Container). NOTE: Always add oil to the reservoir using a system that filters the oil prior to being added to the tank. Never Assume that any oil, even new oil in a new container is contaminant free! To rapidly fill the tank, remove the screw cap from the top of the filter housing and remove the filter cartridge from the bowl. Fill the tank until the oil is at the top of the sight gauge.

UGR 04/06 | Assembly Section |

© 2006 Alamo Group Inc.