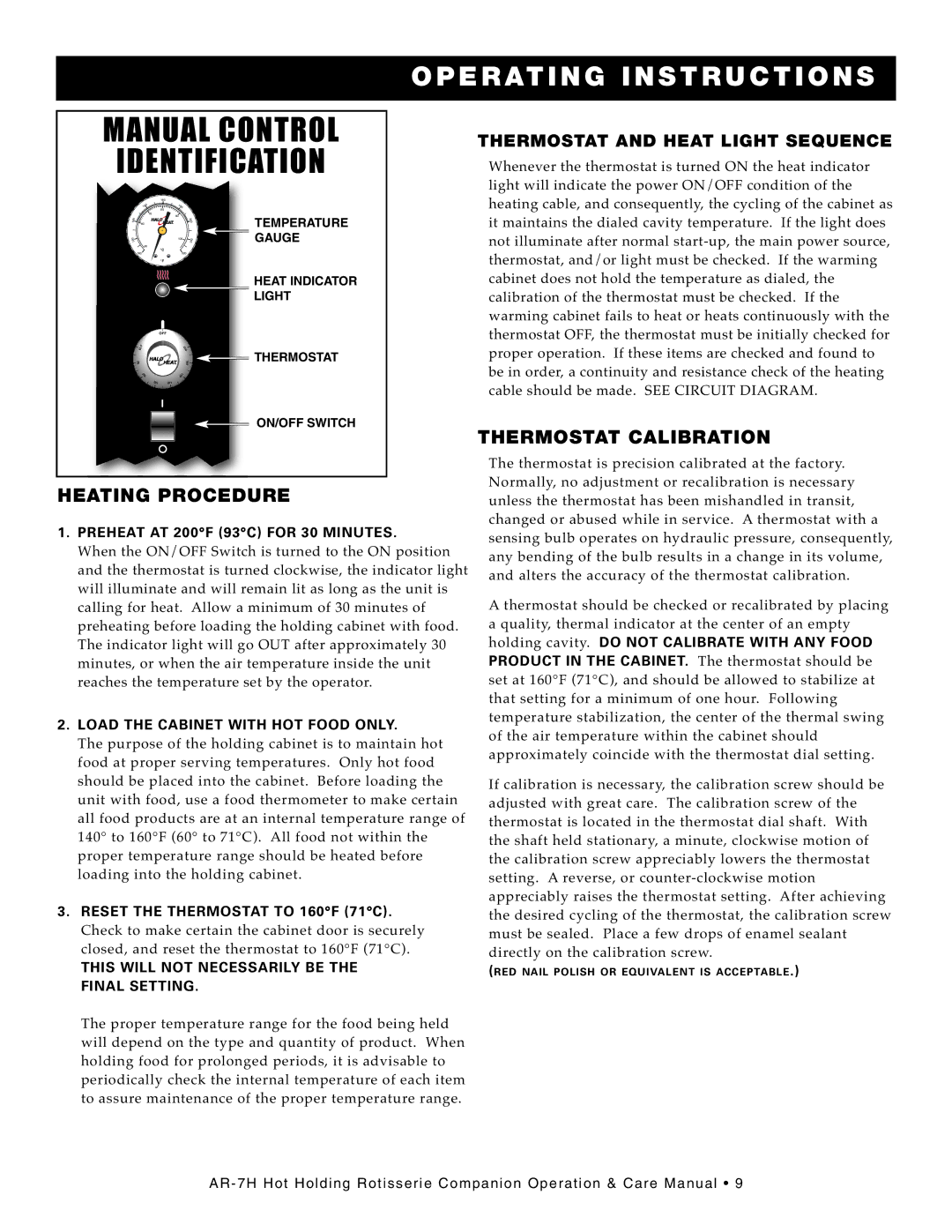

| MAN UAL CONTROL | OPERA TING | INS TRUCTIO | NS | ||||||

|

| THERMOSTAT AND HEAT LIGHT SEQUENCE | ||||||||

| IDE NTIF ICAT ION |

| Whenever the thermostat is turned ON the heat indicator | |||||||

|

|

| 180 |

|

|

|

| light will indicate the power ON/OFF cond ition of the | ||

| 140 |

|

|

| 0 | TEMPERATURE | heating cable, and consequently, the cycling of the cabin et as | |||

| 0 | 0 |

| 100 2 | it maintains the dialed cavity temperature. If the light does | |||||

|

| 16 | 80 | 190 |

|

|

|

|

| |

|

|

| 70 | 90 |

|

|

|

|

|

|

| 100 40 | °C |

| 220 |

|

| not illuminate after normal | |||

|

|

|

|

| 20 |

|

|

|

|

|

|

| 60 |

|

|

|

|

|

|

|

|

| 12 |

|

|

| 01 | GAUGE |

| thermostat, and/or light must be checked . If the warming | ||

|

|

|

|

|

| HEAT INDICATOR | ||||

|

|

| °F |

|

|

|

|

|

|

|

|

|

|

|

|

| LIGHT |

| calibration of the thermostat must be check ed. If the | ||

|

|

| OFF |

|

|

|

| warming cabinet fails to heat or heats continuously with the | ||

| 60 |

|

|

| 0 | THERMOSTAT | thermostat OFF, the thermostat must be initially checked for | |||

| 80 | F |

|

| 018 | proper operation. If these items are checked and found to | ||||

|

|

|

| 20 |

|

| be in order, a continuity and resistance check of the heating | |||

|

| 1 | 120 041 | 0 |

|

|

| |||

|

| 0 |

|

| 61 |

|

| cable should be made. SEE CIRCUIT DIAG RAM. |

| |

|

| 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ON/OFF SWITCH | THER MOSTAT CALIB RATION |

| ||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| The the rmost at is preci sion calibra ted at the factory . | ||

|

|

|

|

|

|

|

| Normal ly, no adj ustm ent or recal ibra tion is neces sar y | ||

HEATING PROCEDURE |

| unl ess the therm osta t has been mishand led in transi t, | ||||||||

1. PREHE AT AT 200°F (93° C) FOR 30 MINUTES. | cha nge d or abused whi le in ser vice. A therm ostat | with a | ||||||||

| When the ON/OFF Switch is turned to the ON position | sen sing bulb ope rates on hydr auli c pressu re, conseq uently , | ||||||||

| any bendi ng of the bul b results in a cha nge in its volume , | |||||||||

| and the thermo stat is turned clockwise, | the indicator light | and alters the accur acy of the therm osta t calib ration. | |||||||

| will illuminate and will remain lit as long as the unit is | A ther mosta t should be checked or reca lib rat ed by plac ing | ||||||||

| calling for heat. Allow a minimum of 30 minutes of | |||||||||

| preheating befo re loading the holdi ng cabinet with food. | a qua lit y, therm al indi cat or at the cente r of an emp ty | ||||||||

| The indicator light will go OUT after approximately 30 | hold ing cavi ty. | DO NOT CALIBRATE WITH ANY FOOD | |||||||

| minutes, or when the air tempe rature inside the unit | PRODUCT IN THE CABINET. The the rmost at should be | ||||||||

| reache s the temperature | set by the operator. | set at 160°F (71° C), and should be allowed to stab ili ze at | |||||||

| tha t setti ng for a minimum of one hour . Foll owing | |||||||||

2. LOAD THE CAB INET WITH HOT FOOD ONLY. | tem pera ture stabilization, the center of the therm al swing | |||||||||

| The pur pose of the holding cabinet is to main tain hot | of the air tem pera ture within the cabinet shoul d |

| |||||||

| foo d at proper servi ng temperat ures. | Only hot food | approxim ate ly coinc ide with the ther mosta t dia l set ting. | |||||||

| should be pla ced into the cabi net . Befo re loadin g the | If calibr atio n is nec essary, the calib rati on screw shoul d be | ||||||||

| unit with food, use a foo d the rmome ter to make certain | adjuste d with grea t care. The cal ibra tion screw of the | ||||||||

| all food products are at an inte rnal temperatu re range of | the rmost at is loca ted in the therm osta t dial shaf t. With | ||||||||

| 140° to 160°F (60° to 71° C). All foo d not within the | the shaft held sta tiona ry, a minute, clockw ise moti on of | ||||||||

| proper temp erature ran ge shou ld be heated bef ore | the calib rati on screw appr ecia bly lowe rs the therm osta t | ||||||||

| loading into the holdin g cabin et. |

| set ting. A reverse , or counter |

| ||||||

|

|

|

|

|

|

|

| appreci abl y raises the the rmos tat sett ing. After achieving | ||

3. | RESET THE THERMOST AT TO 160°F (71°C). | the des ired cyc ling of the thermo stat , the cal ibra tion scre w | ||||||||

| Check to make certain | the cabin et door is securely | must be seal ed. | Plac e a few drops of ena mel sea lant | ||||||

| clo sed , and reset the the rmost at to 160°F (71°C) . | directl y on the calibra tion screw. |

| |||||||

| THIS WILL NOT NECES SARIL Y BE THE | (RED NAIL POLISH OR EQUIVALENT IS ACCEPTABLE .) |

| |||||||

| FINAL SETTING. |

|

|

|

|

| ||||

The proper tem per atur e rang e for the food being hel d will depend on the type and quantity of product. When holdin g food for prolong ed peri ods, it is advis able to period ica lly check the int ernal temperature of each ite m to assure mainten ance of the proper temp erat ure rang e.

AR- 7H Hot Hol di ng Ro tis ser ie Companion Operat ion & Care Manual • 9