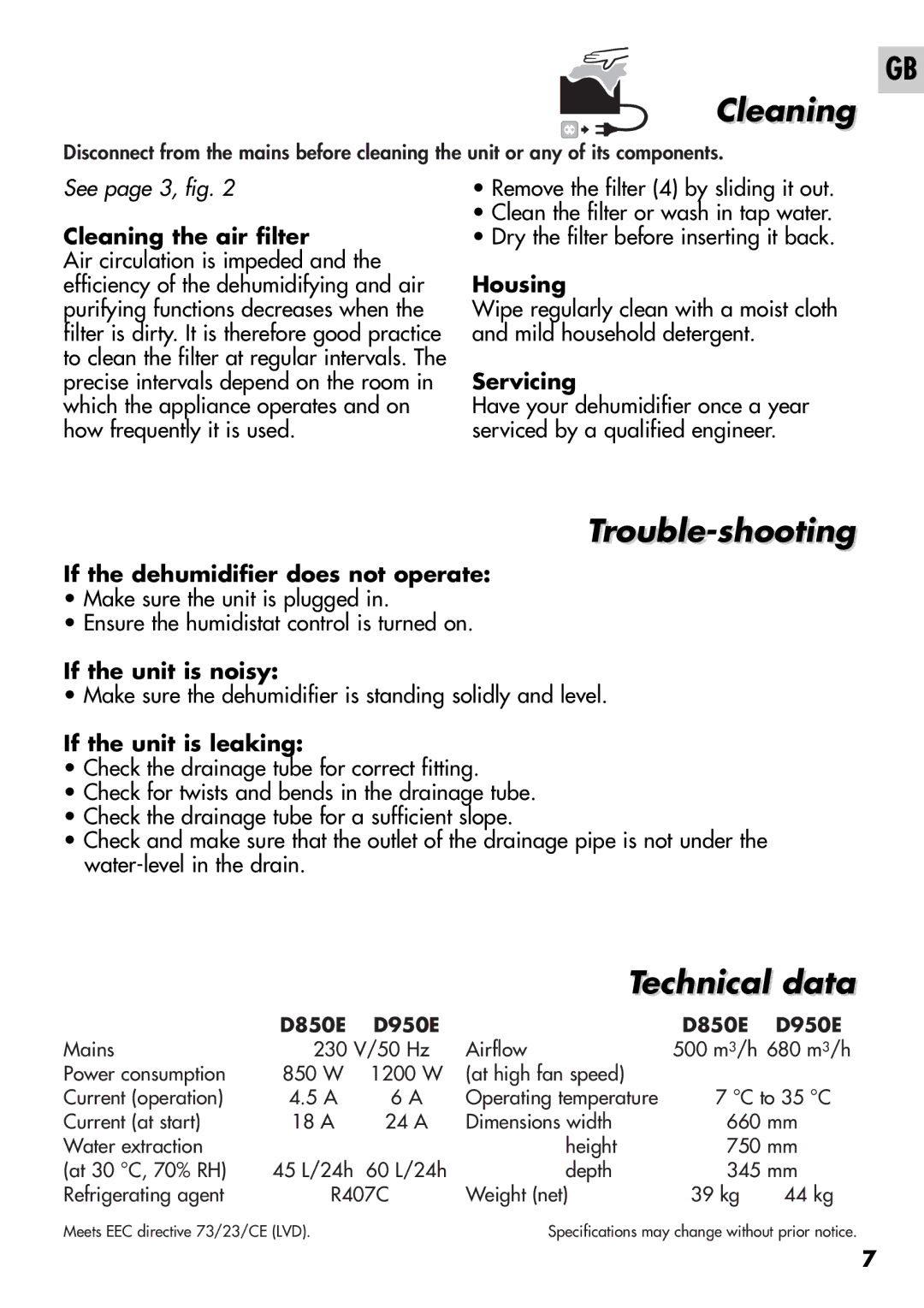

D850E, D950E specifications

Amcor D950E and D850E are advanced packaging solutions designed to meet the needs of various industries, including food and beverage, pharmaceuticals, and consumer goods. These machines stand out for their versatility, efficiency, and innovative technology, making them attractive options for manufacturers seeking to enhance their packaging processes.One of the key features of the Amcor D950E and D850E is their high-speed operation, which allows for rapid production without compromising on quality. Both models are capable of achieving impressive output rates, making them suitable for high-demand environments. The ability to adjust packaging formats effortlessly means that manufacturers can easily switch between different product types, reducing downtime and increasing overall productivity.

In terms of technology, the D950E and D850E utilize advanced servo-driven systems. This technology ensures precise control over the packaging process, resulting in consistent product quality. The servo motors enhance the accuracy of positioning and movement, leading to a more reliable operation. Additionally, these machines are equipped with state-of-the-art vision systems that provide real-time quality checks, ensuring that only products meeting stringent standards are packaged.

The D950E and D850E boast user-friendly interfaces, allowing operators to quickly learn and operate the machines efficiently. The intuitive control systems streamline the packaging process, enabling manufacturers to maximize throughput with minimal training. This aspect is critical in modern manufacturing settings, where adaptability and ease of use are paramount.

Another significant characteristic of these machines is their environmental sustainability. Amcor has integrated energy-efficient technologies into the D950E and D850E, helping to reduce the overall carbon footprint associated with packaging operations. These machines minimize waste through optimized material usage and recycling capabilities, aligning with the increasing demand for environmentally responsible packaging solutions.

Furthermore, the flexibility of the D950E and D850E facilitates the use of various materials, accommodating both rigid and flexible packaging types. This flexibility is invaluable for manufacturers looking to expand their product lines without investing in entirely new machinery. In summary, Amcor D950E and D850E represent cutting-edge advancements in packaging technology, characterized by their high speed, precision, user-friendly operation, and commitment to sustainability. These machines are well-equipped to meet the evolving needs of today's dynamic manufacturing landscape.