b) Start the dryer ... with the burner on, the correct water column (W.C.) reading in inches should be:

Natural Gas | 3.5 | - 4 inches W.C. |

L.P. (liquid propane) Gas | 10.5 | - 11 inches W.C. |

When a gas dryer is first started (during initial time of

NOTE: During the purge period, check to be sure that ALL gas

NOTE: To reset the HSI MODULE if it is in the LOCKOUT MODE, open and close the main door then restart the dryer.

2)Flame Sensor

a)Flame Sensor Fault Code

The HSI Module is equipped with a diagnostic circuit that detects a fault in the Flame Sensor Probe or any related circuits in the internal circuits in the HSI module. When a fault is detected, the “red” L.E.D. (light emitting diode) indicator light will flash 2 blinks. To clear this code either discontinue power to the dryer/HSI Module or replace the FLAME PROBE or HSI MODULE.

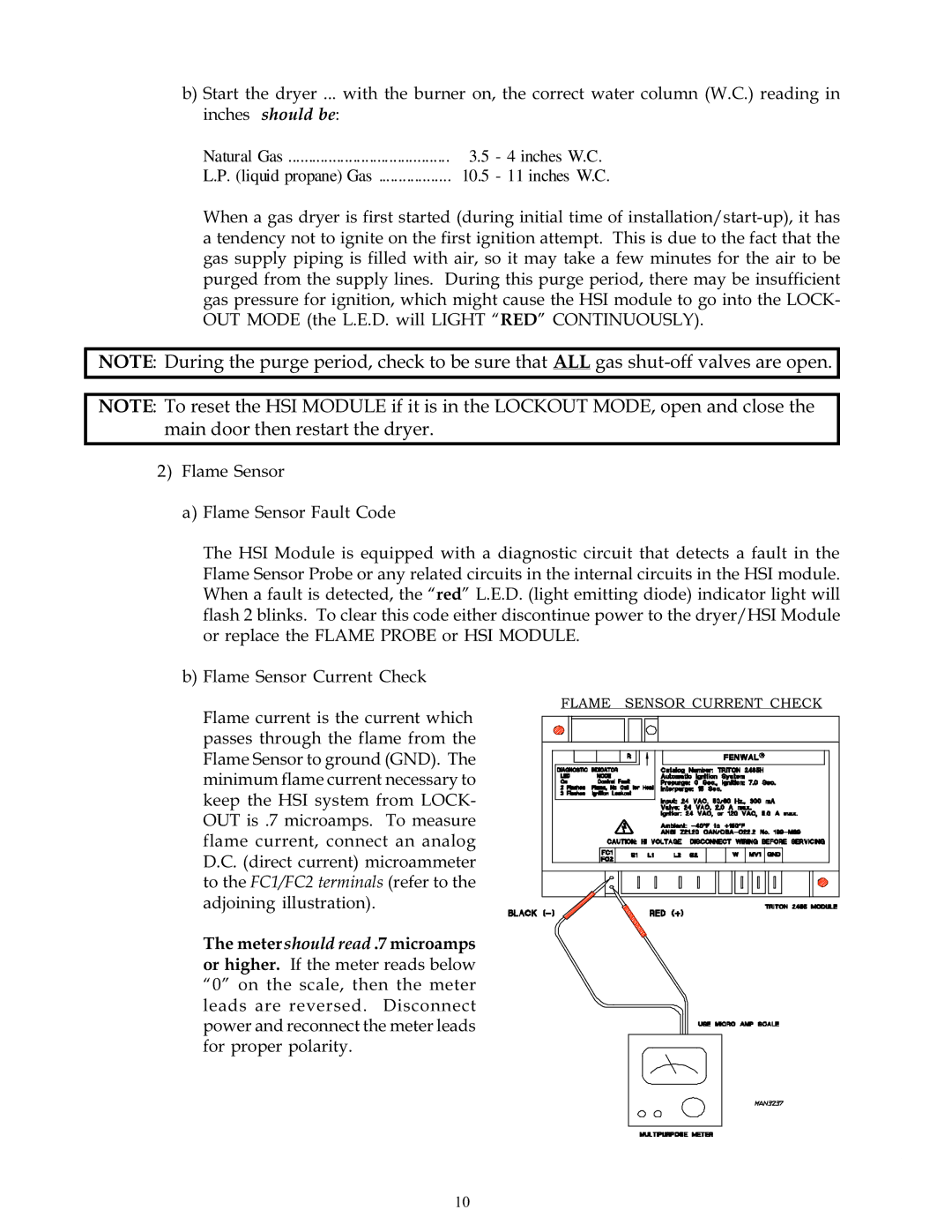

b)Flame Sensor Current Check

Flame current is the current which passes through the flame from the Flame Sensor to ground (GND). The minimum flame current necessary to keep the HSI system from LOCK- OUT is .7 microamps. To measure flame current, connect an analog D.C. (direct current) microammeter to the FC1/FC2 terminals (refer to the adjoining illustration).

The metershould read .7 microamps or higher. If the meter reads below “0” on the scale, then the meter leads are reversed. Disconnect power and reconnect the meter leads for proper polarity.

FLAME SENSOR CURRENT CHECK

10