2038.016 specifications

The American Standard 2038.016 is a prestigious model in the realm of bathroom fixtures, particularly known for its elegant design and durable functionality. This toilet embodies a blend of sophistication and innovation, catering to a diverse range of user needs while maintaining American Standard's reputation for quality.One of the most notable features of the 2038.016 is its powerful, efficient flushing system. Utilizing the brand’s proprietary Champion 4 technology, this model boasts a 4-inch flushing valve that allows for a robust flush without sacrificing water efficiency. Capable of flushing down 1,600 grams of solid waste in a single go, it minimizes clogs while ensuring a cleaner bowl. This impressive flushing capability is complemented by its WaterSense certification, which highlights its ability to conserve water without compromising performance.

The design of the American Standard 2038.016 is equally impressive. It features a sleek, elongated bowl design that provides extra comfort, making it an ideal choice for families or those who desire a more spacious seating area. The toilet's height is also ADA compliant, which is beneficial for individuals with mobility challenges. Its compact size makes it suitable for various bathroom layouts, effectively balancing aesthetics and functionality.

In terms of construction, this model is crafted from high-quality vitreous china, which not only enhances its durability but also makes it easy to clean and resistant to stains. The gleaming white finish adds a modern touch, making it a versatile choice for almost any bathroom décor.

Another technological advancement found in the American Standard 2038.016 is its EverClean surface. This innovative feature helps inhibit the growth of stain and odor-causing bacteria, mold, and mildew, ensuring that the toilet remains hygienic over time. It significantly reduces the need for harsh cleaning agents and frequent maintenance, thus offering a more sustainable and eco-friendly solution.

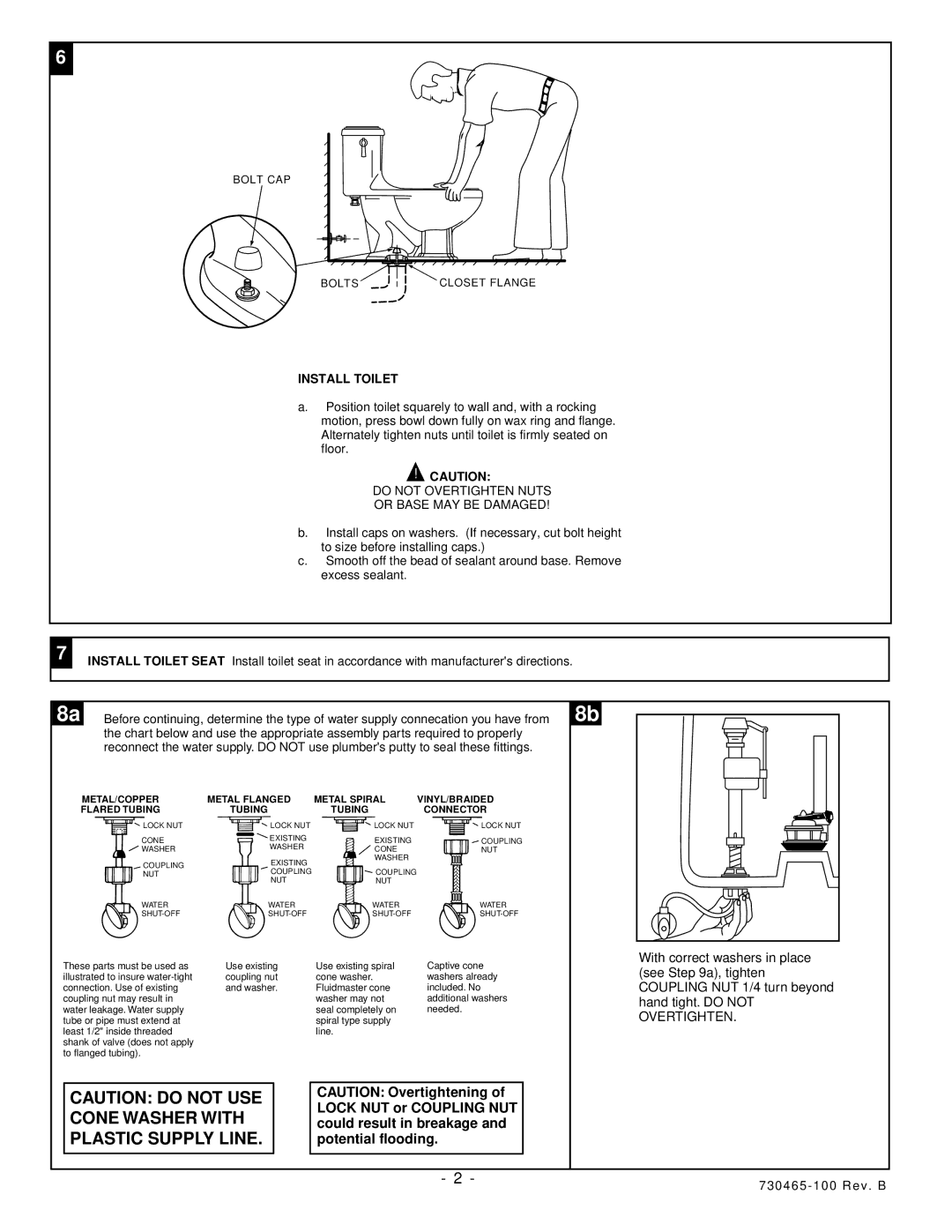

Installation is straightforward, with a standard size that fits most plumbing configurations, whether it’s a new build or a remodel. Overall, the American Standard 2038.016 presents an ideal fusion of cutting-edge technology, user-friendly design, and high-quality materials, making it a leading choice for countless households seeking a reliable and stylish toilet option. Its combination of efficiency, comfort, and aesthetic appeal sets a high standard in the increasingly competitive bathroom fixture market.