27

INSTALLATION OF HORIZONTAL THROUGH THE WALL VENT SYSTEMIf you are in stal lin g your syste m so tha t it ven ts th roug h roo f, ple ase

refe r to sec tio n tit led VE RTIC AL VE NT TER MIN AL IN STAL LATI ON.

VENT TERMINAL INSTALLATION, SIDEWALL

1. I nsta ll the vent t ermi nal by usin g the co ver pl ate as a temp late to

mark the hole for the vent pipe to pass through the wall. BEWARE

OF CONCEALED WIRING A ND PIPING INSIDE THE WALL.

2. If the Vent Terminal is being installed on the outside of a nished

wall, it may be easier to mark both the inside and outside wall.

Align the holes by drillin g a hole throug h the center of the

template from the inside through to the outside. Th e template

can now be positioned on the outside wall using the drilled hole

as a centering point for the template.

3. A) MASONRY SIDE WALLS

C hisel an opening app roximately one half inc h (1.3 cm) larger

than the marked circle.

B) WOO DEN SIDE WALLS

D ril l a pilo t hol e appr oxim ate ly one quar ter in ch (0. 64 cm) outsi de

of the marked circl e. This pilot hole is used as a starting point

for a saws-all or sabre saw blade. Cut around the marked circle

staying approximately one quarter inch (0.64 cm) outside of the

line. (This will allow the vent to easily slide through the opening.

The resulting gap will be covered up by the Vent Terminal cover

plate.) Repeat this step on inside wall if necessar y.

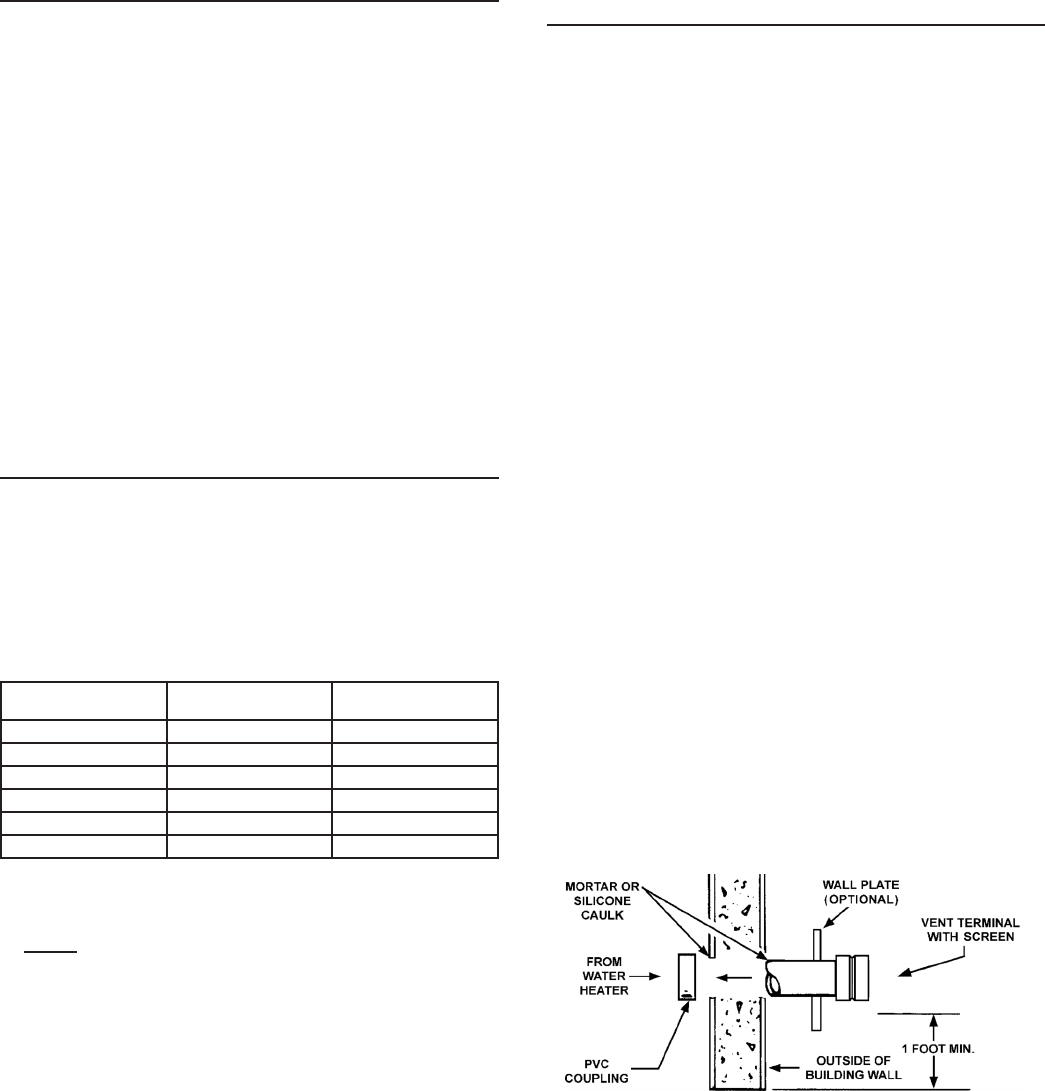

Cut a length of pipe about 3.5 inches (8.9 cm) longer than the wall

thi ckne ss at th e open ing . Glue the ven t term inal to this sect ion of pipe.

Slide the wall plate over the pipe to stop aga inst the vent ter minal.

Place a bead of caulking (not supplied) around the gap between the

pipe and cover plate. Appl y enough to ll some of the gap between

the pipe and wall. Place some of the caulking on the back of the plate

to hold it against the wall after installation. If the vent pipe is installed

up to the wall, with a coupling on the end against the wall o pening,

the pipe with the vent terminal can b e prepared for gluing before

inserting through the wall. Sli de the pipe through the wall and insert

into the coupling on the other side of the wall, making sure that t he

vent terminal ends up pointed in the correct position, see Figu re 12.

Figure 12: VENT TERMINATION

VENT PIPE TERMINATIONThe rst step is to determine where the vent pipe will terminate. See

Figures 12, “Figure: 13A”, and “Figure: 14”. The vent may terminate

thr ough a sidew all as show n in Fig ure 12 an d “Fig ure: 14” or thr oug h

the roof as shown in “Figure: 15” and “Figure: 16”.

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current e dition of the

National Fuel Gas C ode, (ANSI Z223.1, 12.9.1 through 12.9.4) or

the N atur al Gas and Pr opan e Inst all atio n Cod e (CAN /CS A-B 149.1).

See “Figure: 15” and “Figure: 16”.

Instructions on proper installat ion through a sidewall are provided

in Figures 12, “Figure: 13A”, and “Figure: 14”.

Plan the vent system layout so that proper clea rances are

maintained from plumbing and wir ing.

Vent pipes ser ving power vented water heaters are classied by

building codes as vent connectors. Required clear ances from

combustible mate rials must be provided in acc ordance with

information in this manual under FACTS TO CONSIDER ABOUT

LOCATION and INSTALLING THE WATER HEATER, and with the

National Fuel Gas Code and local co des.

PLANNING THE VENT SYSTEMPlan the ro ute of the vent system from the exhaust elbow to the

planned location of the vent terminal.

1. Layout total vent system to use a minimum of vent pipe and

elbows.

2. This water heater is capable of venting ue gases in equivalent

feet of pipe as listed in Table 7.

Table 7

Number of

90° Elbows

2” Maximum

Pipe - ft. (m)

3” Maximum

Pipe - ft. (m)

140 (12.19) 120 (36.57)

235 (10.66) 115 (35.05)

330 (9.14) 110 (33.52)

425 (7.62) 105 (32)

5 20 (6.09) 100 (30.48)

615 (4.57) 95 (28.95)

The minimum vent length for each of the pipe size is one 90° elbow

plus 2’ and 7’ (0.61 m and 2.1 m) of straight pipe for air intake and

exhaust vent respectively and the appropr iate termination.

NOTE: The eq uiva len t feet (m) of pip e list ed ab ove ar e excl usiv e

of the termination. That is, the termination, with an installed

screen, is as sumed to be i n the system a nd the remainder of

the system must not exce ed the lengths and numb er of elbows

shown in Table 7.

If using 2 ” inch vent pipe: A 2” diameter vent pipe must be

inserted and glued to the exhaust elbow a ssembly.

If using 3” inch vent pipe: Two inches (5.1cm) of 2” diameter pipe

must be inserted and glued to the exhaust elbow assembly before

adding a 2’ x 3” reducer to acquire the desired pipe diameter. A

3” coupling (supplied locally-a schedule 40 DWV) vent terminal

must be obtained. A 3” diameter scr een is supplied in the vent

kit.