Offset Tilt Bowl Mixer (OTBM) specifications

The AMF Offset Tilt Bowl Mixer (OTBM) is a revolutionary piece of equipment in the bakery and food processing industry. Designed to enhance dough mixing efficiency and consistency, the OTBM employs advanced technologies to meet the diverse needs of modern food manufacturers. Its unique offset tilt design allows for effective mixing while minimizing the physical footprint, making it an ideal choice for facilities with space constraints.One of the standout features of the OTBM is its ability to handle a wide variety of doughs, from stiff bread doughs to hydrated cake mixtures. The mixer is equipped with an innovative bowl design that optimizes the mixing process, ensuring all ingredients are uniformly combined. This results in consistent product quality, which is crucial for bakeries that need to meet high standards for their goods.

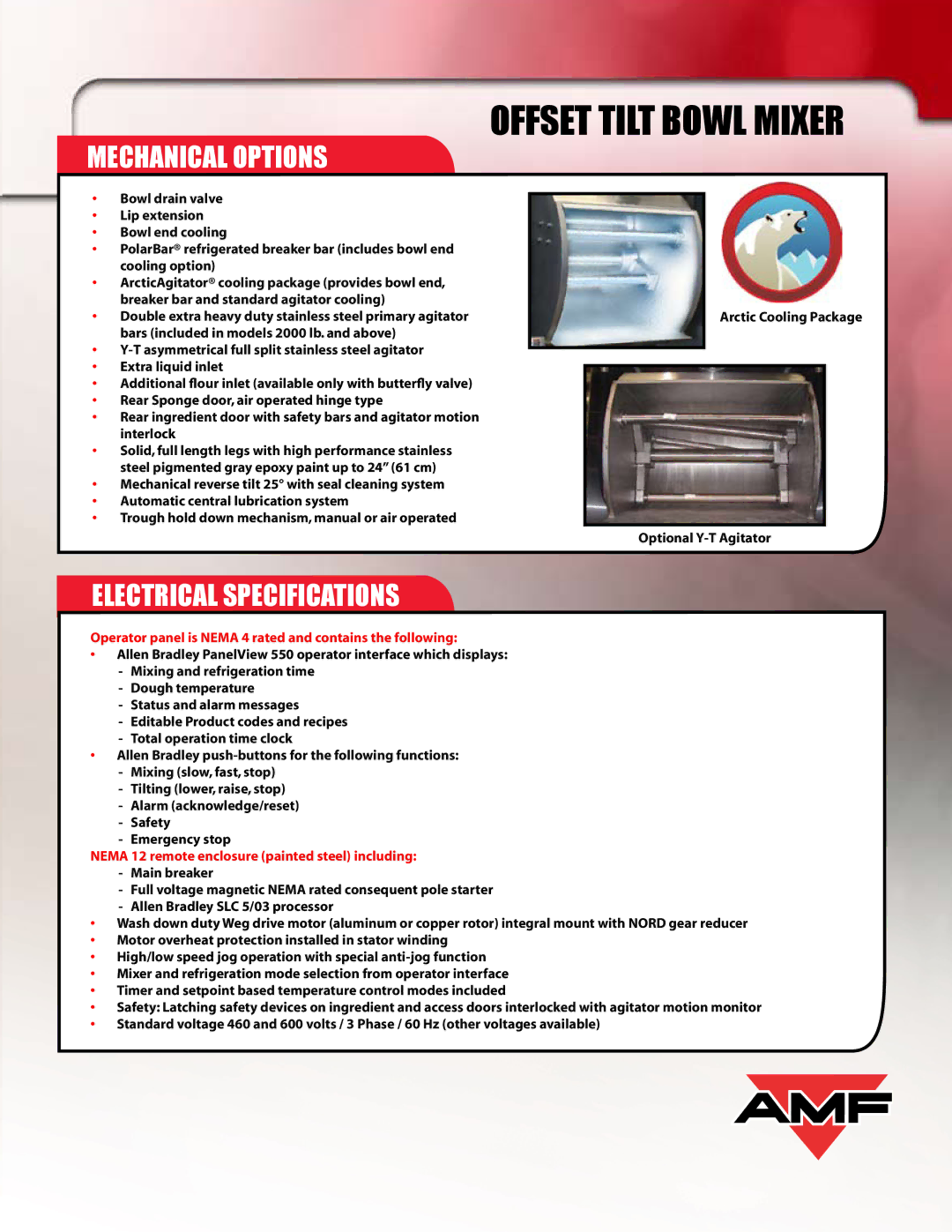

The OTBM integrates a powerful drive system that allows for adjustable mixing speeds, catering to different dough types and mixing requirements. This versatility not only enhances performance but also enables bakers to fine-tune their recipes for optimal results. The mixer can be programmed for specific mixing times and speeds, providing precise control over the dough development process.

In addition to its robust mixing capabilities, the AMF Offset Tilt Bowl Mixer is designed with operator safety and ease of use in mind. The tilt function simplifies the unloading process, allowing operators to easily access the bowl without straining. The intuitive control panel is user-friendly, ensuring that staff can operate the machine with minimal training.

Maintenance is made straightforward thanks to the OTBM's accessible design. Regular cleaning and upkeep are simplified, which is vital in the food industry where hygiene standards are paramount. Constructed from high-quality stainless steel, the mixer is built to withstand the rigors of daily use while resisting corrosion and ensuring longevity.

Another significant characteristic of the AMF OTBM is its efficient energy consumption. The mixer is designed to minimize operational costs, contributing to a bakery's bottom line without compromising performance. By combining advanced technology with user-friendly features, the AMF Offset Tilt Bowl Mixer meets the evolving demands of the food production industry, making it an invaluable asset for any commercial bakery.