Connections and Wiring

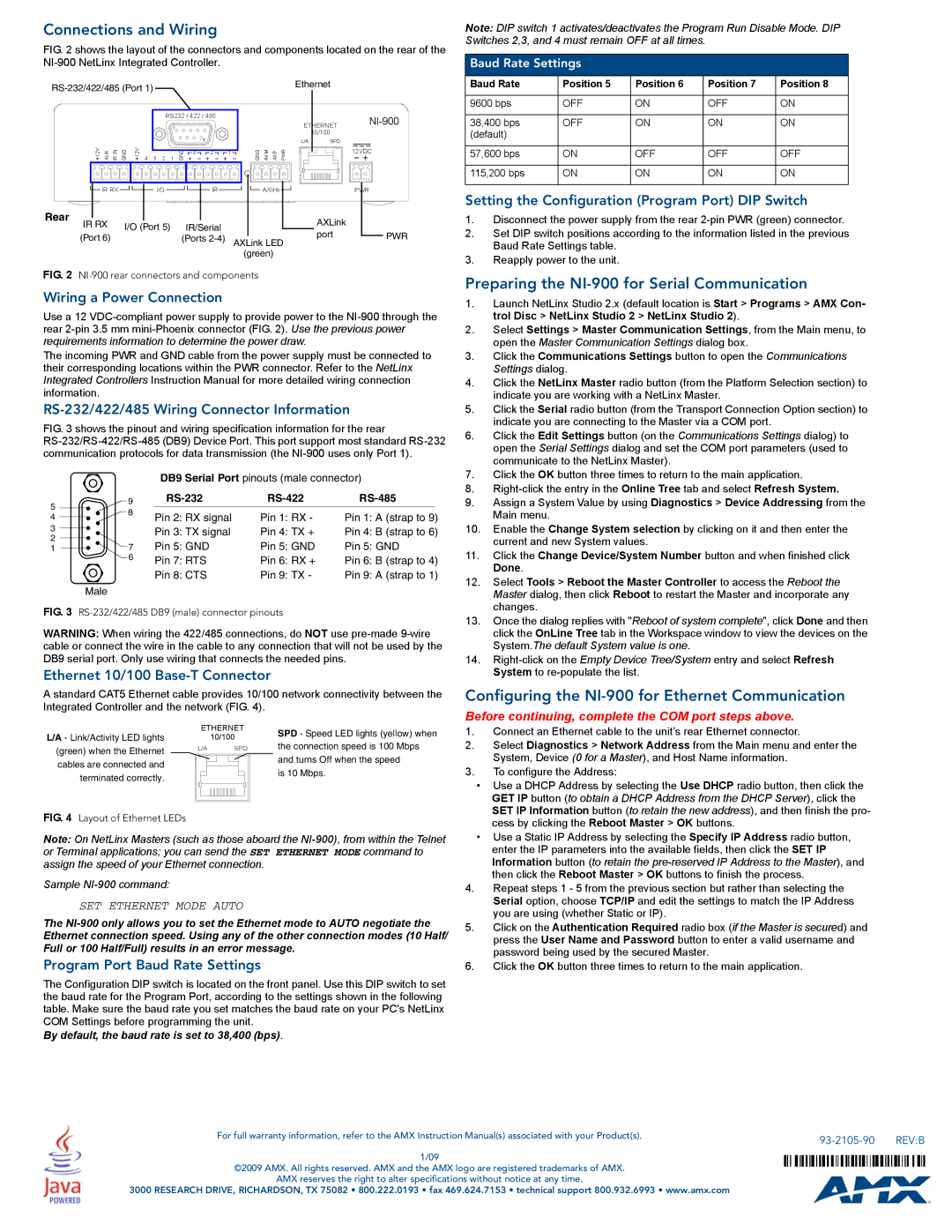

FIG. 2 shows the layout of the connectors and components located on the rear of the NI-900 NetLinx Integrated Controller.

| Ethernet | |

|

|

|

|

|

|

|

|

| RS232 / 422 / 485 |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ETHERNET | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10/100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| L/A | SPD |

|

12V | AUX IR IN | GND | 12V | 4 | 3 | 2 | 1 | GND | 3 | 2 | 1 | GND | AXM AXP | PWR |

| 12VDC |

|

|

|

|

| ||||||||||||

| IR RX |

|

|

|

| I/O |

|

|

| IR |

|

| AXlink |

|

| PWR |

Rear |

|

|

|

| AXLink |

|

|

IR RX | I/O (Port 5) | IR/Serial |

|

|

|

| |

(Port 6) |

|

| port |

| PWR | ||

| (Ports |

|

|

| |||

| AXLink LED |

|

| ||||

(green)

FIG. 2 NI-900 rear connectors and components

Wiring a Power Connection

Use a 12

The incoming PWR and GND cable from the power supply must be connected to their corresponding locations within the PWR connector. Refer to the NetLinx Integrated Controllers Instruction Manual for more detailed wiring connection information.

RS-232/422/485 Wiring Connector Information

FIG. 3 shows the pinout and wiring specification information for the rear RS-232/RS-422/RS-485 (DB9) Device Port. This port support most standard RS-232 communication protocols for data transmission (the NI-900 uses only Port 1).

|

| DB9 Serial Port pinouts (male connector) | |||

5 | 9 |

|

|

| |

8 | Pin 2: RX signal | Pin 1: RX - | Pin 1: A (strap to 9) | ||

4 | |||||

| |||||

3 |

| Pin 3: TX signal | Pin 4: TX + | Pin 4: B (strap to 6) | |

2 | 7 | Pin 5: GND | Pin 5: GND | Pin 5: GND | |

1 | |||||

| 6 | Pin 7: RTS | Pin 6: RX + | Pin 6: B (strap to 4) | |

|

| Pin 8: CTS | Pin 9: TX - | Pin 9: A (strap to 1) | |

Male

FIG. 3 RS-232/422/485 DB9 (male) connector pinouts

WARNING: When wiring the 422/485 connections, do NOT use

Ethernet 10/100 Base-T Connector

A standard CAT5 Ethernet cable provides 10/100 network connectivity between the Integrated Controller and the network (FIG. 4).

|

| ETHERNET | SPD - Speed LED lights (yellow) when | ||

L/A - Link/Activity LED lights |

|

| 10/100 |

| |

|

|

| the connection speed is 100 Mbps | ||

(green) when the Ethernet |

| L/A | SPD | ||

|

|

|

|

| |

cables are connected and | and turns Off when the speed | |

is 10 Mbps. | ||

terminated correctly. | ||

|

FIG. 4 Layout of Ethernet LEDs

Note: On NetLinx Masters (such as those aboard the

Sample

SET ETHERNET MODE AUTO

The

Program Port Baud Rate Settings

The Configuration DIP switch is located on the front panel. Use this DIP switch to set the baud rate for the Program Port, according to the settings shown in the following table. Make sure the baud rate you set matches the baud rate on your PC's NetLinx COM Settings before programming the unit.

By default, the baud rate is set to 38,400 (bps).

Note: DIP switch 1 activates/deactivates the Program Run Disable Mode. DIP Switches 2,3, and 4 must remain OFF at all times.

Baud Rate Settings

Baud Rate | Position 5 | Position 6 | Position 7 | Position 8 |

|

|

|

|

|

9600 bps | OFF | ON | OFF | ON |

|

|

|

|

|

38,400 bps | OFF | ON | ON | ON |

(default) |

|

|

|

|

|

|

|

|

|

57,600 bps | ON | OFF | OFF | OFF |

|

|

|

|

|

115,200 bps | ON | ON | ON | ON |

|

|

|

|

|

Setting the Configuration (Program Port) DIP Switch

1.Disconnect the power supply from the rear

2.Set DIP switch positions according to the information listed in the previous Baud Rate Settings table.

3.Reapply power to the unit.

Preparing the NI-900 for Serial Communication

1.Launch NetLinx Studio 2.x (default location is Start > Programs > AMX Con- trol Disc > NetLinx Studio 2 > NetLinx Studio 2).

2.Select Settings > Master Communication Settings, from the Main menu, to open the Master Communication Settings dialog box.

3.Click the Communications Settings button to open the Communications Settings dialog.

4.Click the NetLinx Master radio button (from the Platform Selection section) to indicate you are working with a NetLinx Master.

5.Click the Serial radio button (from the Transport Connection Option section) to indicate you are connecting to the Master via a COM port.

6.Click the Edit Settings button (on the Communications Settings dialog) to open the Serial Settings dialog and set the COM port parameters (used to communicate to the NetLinx Master).

7.Click the OK button three times to return to the main application.

8.

9.Assign a System Value by using Diagnostics > Device Addressing from the Main menu.

10.Enable the Change System selection by clicking on it and then enter the current and new System values.

11.Click the Change Device/System Number button and when finished click Done.

12.Select Tools > Reboot the Master Controller to access the Reboot the Master dialog, then click Reboot to restart the Master and incorporate any changes.

13.Once the dialog replies with "Reboot of system complete", click Done and then click the OnLine Tree tab in the Workspace window to view the devices on the System.The default System value is one.

14.

Configuring the NI-900 for Ethernet Communication

Before continuing, complete the COM port steps above.

1.Connect an Ethernet cable to the unit’s rear Ethernet connector.

2.Select Diagnostics > Network Address from the Main menu and enter the System, Device (0 for a Master), and Host Name information.

3.To configure the Address:

•Use a DHCP Address by selecting the Use DHCP radio button, then click the GET IP button (to obtain a DHCP Address from the DHCP Server), click the SET IP Information button (to retain the new address), and then finish the pro- cess by clicking the Reboot Master > OK buttons.

•Use a Static IP Address by selecting the Specify IP Address radio button, enter the IP parameters into the available fields, then click the SET IP Information button (to retain the

4.Repeat steps 1 - 5 from the previous section but rather than selecting the Serial option, choose TCP/IP and edit the settings to match the IP Address you are using (whether Static or IP).

5.Click on the Authentication Required radio box (if the Master is secured) and press the User Name and Password button to enter a valid username and password being used by the secured Master.

6.Click the OK button three times to return to the main application.

For full warranty information, refer to the AMX Instruction Manual(s) associated with your Product(s). |

| REV:B |

|

1/09

©2009 AMX. All rights reserved. AMX and the AMX logo are registered trademarks of AMX.

AMX reserves the right to alter specifications without notice at any time.

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 • 800.222.0193 • fax 469.624.7153 • technical support 800.932.6993 • www.amx.com