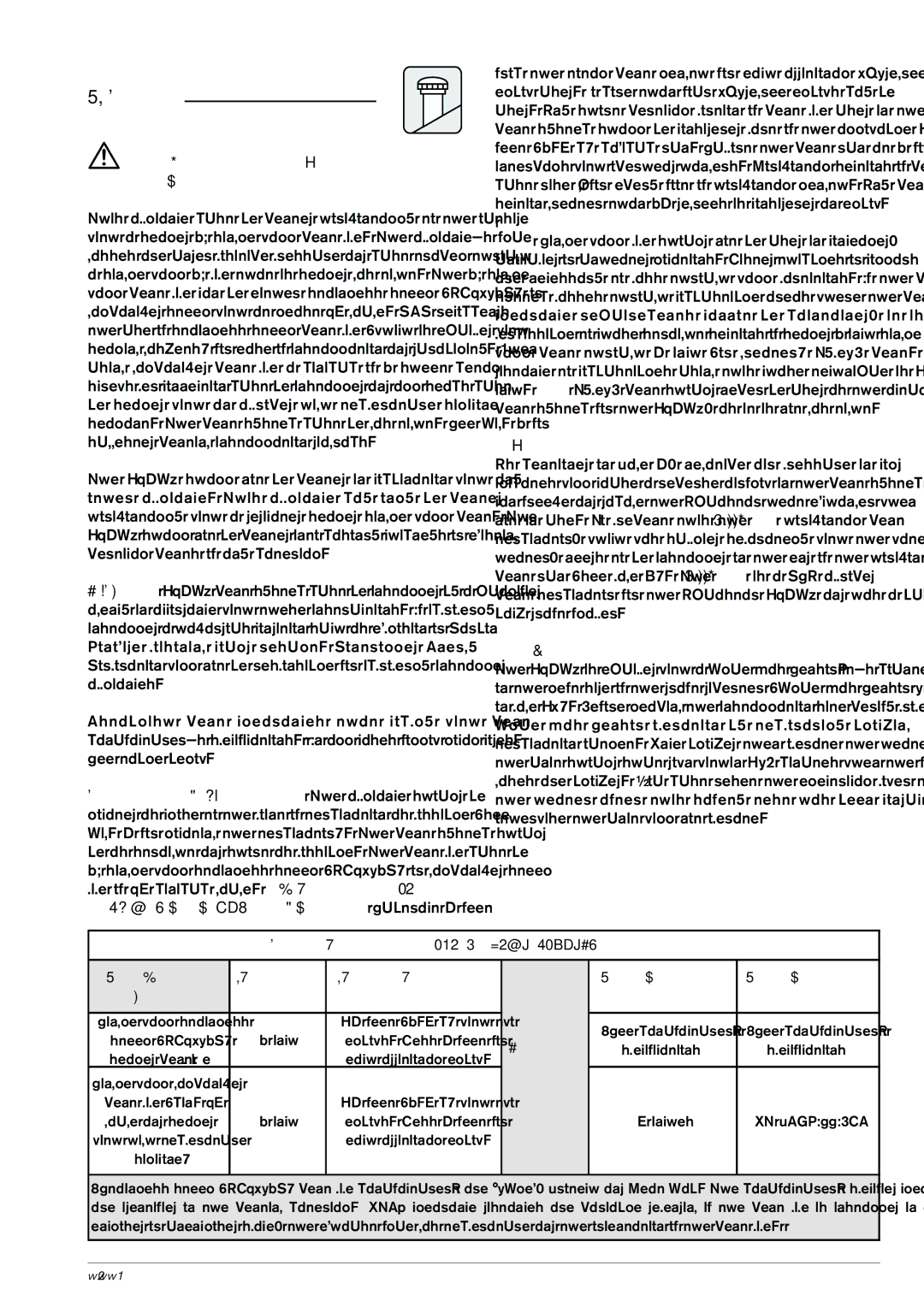

125FX NG, 125FX LP specifications

The AquaStar 125FX NG and 125FX LP are two remarkable models in the world of high-efficiency heaters. Designed for optimal performance in residential settings, these devices cater to diverse needs with their advanced technology and user-friendly features.The AquaStar 125FX NG model operates using natural gas, while the 125FX LP utilizes liquid propane. This versatility allows users to choose the most suitable fuel type for their home setup. Both models boast an impressive energy efficiency rating, ensuring minimal energy waste while delivering reliable hot water on demand. This makes them not only cost-effective but also an eco-friendly choice for homeowners looking to reduce their carbon footprint.

One of the standout features of the AquaStar 125FX series is its compact design, which makes it ideal for installations in small spaces. With a sleek and modern appearance, it can easily blend into various interior aesthetics without occupying excessive room. The units are also relatively lightweight, facilitating a simple installation process.

In terms of performance, both the NG and LP models are equipped with a powerful BTU input that guarantees quick heating capabilities. They can provide ample hot water for multiple applications simultaneously, such as showers and dishwashing, making them perfect for busy households. Furthermore, the AquaStar 125FX units utilize advanced burner technology that ensures efficient combustion, resulting in a constant supply of hot water without fluctuations in temperature.

Safety is paramount in the design of the AquaStar 125FX series. Each heater is equipped with comprehensive safety features, including built-in vents for proper exhaust and a flame failure device that shuts the heater off if the flame goes out unexpectedly.

The control panel on both models is intuitive, allowing users to easily adjust the water temperature and monitor the unit's performance. Additionally, the AquaStar 125FX series is designed for longevity, with corrosion-resistant materials that withstand the rigors of daily use.

In summary, the AquaStar 125FX NG and 125FX LP are perfect examples of modern, efficient water heating technology. With their compact design, rapid heating capabilities, and robust safety features, these models present an excellent choice for any home looking to enhance its hot water supply while maintaining efficiency and environmental responsibility.