GAS PIPING, CONNECTIONS and Gas Regulator

Before connecting the gas supply, check the rating plate on the right side of the front cover to be sure that the heater is rated for the same gas to which it will be connected.

In the United States: The installation must conform with local codes or, in the absence of local codes, the National Fuel Gas Code ANSI Z223.1/NFPA 54.

In Canada: The Installation should conform with CGA B149 INSTALLATION CODES and /or local installation codes.

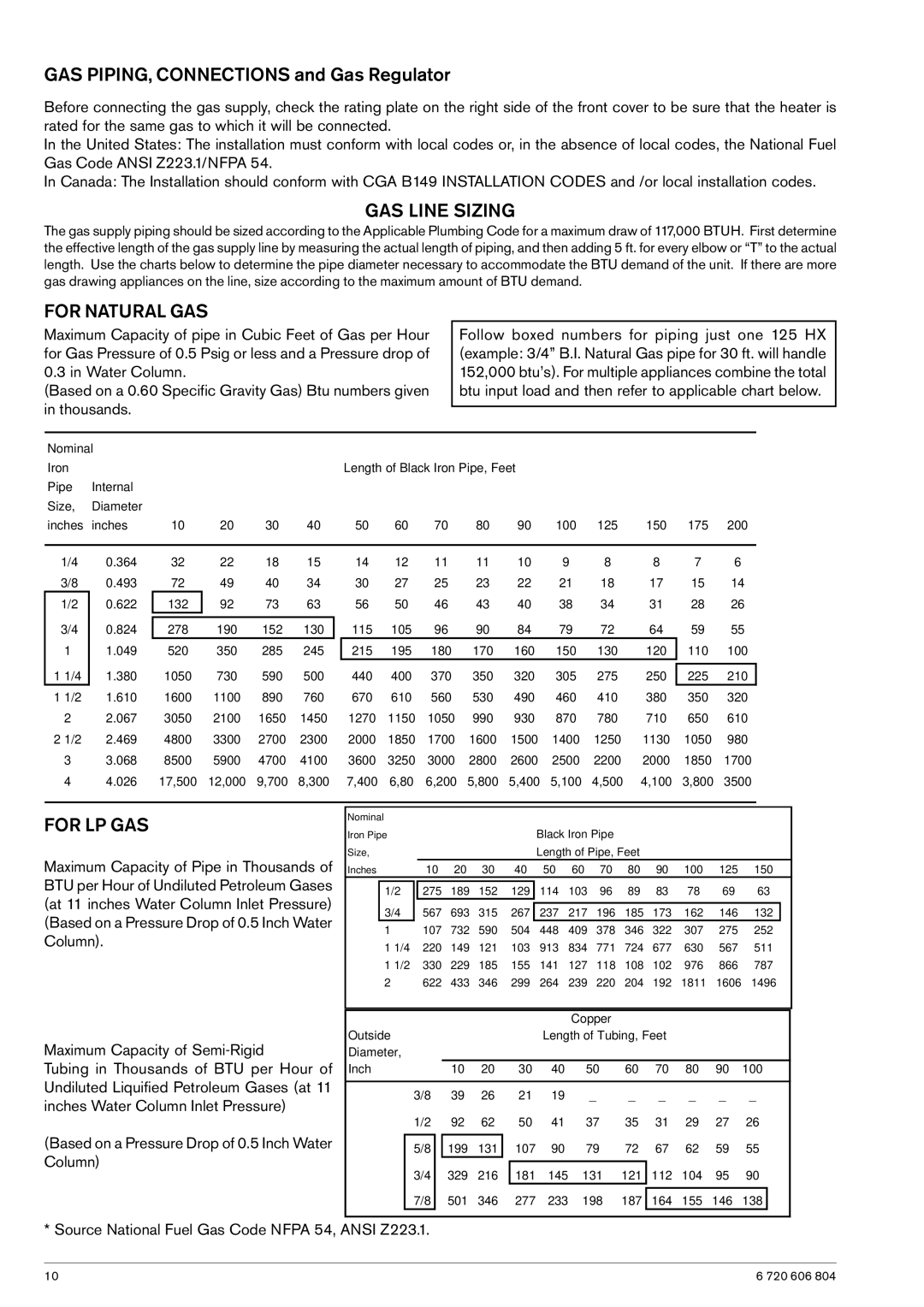

GAS LINE SIZING

The gas supply piping should be sized according to the Applicable Plumbing Code for a maximum draw of 117,000 BTUH. First determine the effective length of the gas supply line by measuring the actual length of piping, and then adding 5 ft. for every elbow or “T” to the actual length. Use the charts below to determine the pipe diameter necessary to accommodate the BTU demand of the unit. If there are more gas drawing appliances on the line, size according to the maximum amount of BTU demand.

FOR NATURAL GAS

Maximum Capacity of pipe in Cubic Feet of Gas per Hour for Gas Pressure of 0.5 Psig or less and a Pressure drop of 0.3 in Water Column.

(Based on a 0.60 Specific Gravity Gas) Btu numbers given in thousands.

Follow boxed numbers for piping just one 125 HX (example: 3/4” B.I. Natural Gas pipe for 30 ft. will handle 152,000 btu’s). For multiple appliances combine the total btu input load and then refer to applicable chart below.

Nominal |

|

|

|

|

|

|

|

|

|

|

|

|

| |

Iron |

|

|

|

|

| Length of Black Iron Pipe, Feet |

|

|

|

| ||||

Pipe | Internal |

|

|

|

|

|

|

|

|

|

|

|

|

|

Size, | Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

inches | inches | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 200 |

| 1/4 | 0.364 |

| 3/8 | 0.493 |

| 1/2 | 0.622 |

| 3/4 | 0.824 |

| 1 | 1.049 |

1 | 1/4 | 1.380 |

1 | 1/2 | 1.610 |

| 2 | 2.067 |

2 | 1/2 | 2.469 |

33.068

44.026

32 | 22 | 18 | 15 |

72 | 49 | 40 | 34 |

132 | 92 | 73 | 63 |

|

|

|

|

278 | 190 | 152 | 130 |

520 | 350 | 285 | 245 |

1050 730 590 500

1600 1100 890 760

3050 2100 1650 1450

4800 3300 2700 2300

8500 5900 4700 4100

17,500 12,000 9,700 8,300

14 | 12 | 11 | 11 | 10 | 9 | 8 | 8 | 7 | 6 |

30 | 27 | 25 | 23 | 22 | 21 | 18 | 17 | 15 | 14 |

56 | 50 | 46 | 43 | 40 | 38 | 34 | 31 | 28 | 26 |

115 | 105 | 96 | 90 | 84 | 79 | 72 | 64 | 59 | 55 |

215 | 195 | 180 | 170 | 160 | 150 | 130 | 120 | 110 | 100 |

|

|

|

|

|

|

|

|

|

|

440 | 400 | 370 | 350 | 320 | 305 | 275 | 250 | 225 | 210 |

670 | 610 | 560 | 530 | 490 | 460 | 410 | 380 | 350 | 320 |

1270 | 1150 | 1050 | 990 | 930 | 870 | 780 | 710 | 650 | 610 |

2000 | 1850 | 1700 | 1600 | 1500 | 1400 | 1250 | 1130 | 1050 | 980 |

3600 | 3250 | 3000 | 2800 | 2600 | 2500 | 2200 | 2000 | 1850 | 1700 |

7,400 | 6,80 | 6,200 | 5,800 | 5,400 | 5,100 | 4,500 | 4,100 | 3,800 | 3500 |

FOR LP GAS

Maximum Capacity of Pipe in Thousands of BTU per Hour of Undiluted Petroleum Gases (at 11 inches Water Column Inlet Pressure) (Based on a Pressure Drop of 0.5 Inch Water Column).

Maximum Capacity of

Tubing in Thousands of BTU per Hour of Undiluted Liquified Petroleum Gases (at 11 inches Water Column Inlet Pressure)

(Based on a Pressure Drop of 0.5 Inch Water Column)

Nominal |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Iron Pipe |

|

|

|

|

| Black Iron Pipe |

|

|

|

|

|

| |||

Size, |

|

|

|

|

| Length of Pipe, Feet |

|

|

|

|

| ||||

Inches | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/2 |

| 275 | 189 | 152 | 129 | 114 | 103 | 96 | 89 | 83 | 78 | 69 | 63 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3/4 | 567 | 693 | 315 | 267 | 237 | 217 | 196 | 185 | 173 | 162 | 146 | 132 |

| |

1 | 107 | 732 | 590 | 504 | 448 | 409 | 378 | 346 | 322 | 307 | 275 | 252 |

| ||

1 1/4 | 220 | 149 | 121 | 103 | 913 | 834 | 771 | 724 | 677 | 630 | 567 | 511 |

| ||

1 1/2 | 330 | 229 | 185 | 155 | 141 | 127 | 118 | 108 | 102 | 976 | 866 | 787 |

| ||

2 | 622 | 433 | 346 | 299 | 264 | 239 | 220 | 204 | 192 | 1811 | 1606 | 1496 |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Copper |

|

|

|

|

|

|

Outside |

|

|

|

|

| Length of Tubing, Feet |

|

|

|

| ||||

Diameter, |

|

|

|

|

|

|

|

|

|

|

|

|

| |

Inch | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| |||

|

|

|

|

|

|

|

|

|

|

|

| |||

3/8 | 39 | 26 | 21 | 19 | _ | _ | _ | _ | _ | _ |

| |||

1/2 | 92 | 62 | 50 | 41 | 37 | 35 | 31 | 29 | 27 | 26 |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5/8 |

| 199 | 131 | 107 | 90 | 79 | 72 | 67 | 62 | 59 | 55 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3/4 | 329 | 216 |

| 181 | 145 | 131 | 121 | 112 | 104 | 95 | 90 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 7/8 | 501 | 346 | 277 | 233 | 198 | 187 | 164 | 155 | 146 | 138 |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* Source National Fuel Gas Code NFPA 54, ANSI Z223.1.

10 | 6 720 606 804 |