1.Choose a bilge pump mounting location in the lowest accessible part of the bilge. In this location, pump will remove the last 1" (2.54 cm) of standing water. Also, pump should be as close to the

2.To install mounting pad on fiberglass hull:

Sand gelcoat or paint off the mounting surface to create an area that is 3" (7.6cm) wider than the mounting pad on each side.

Completely cover the mounting pad with fiberglass. Saturate the fiberglass with resin, and press the fiberglass edges down against the hull to adhere the pad in place. Roll out the fiberglass to remove any uneven surfaces, air bubbles, or excess resin.

To install mounting pad on aluminum hull:

If your boat is not equipped with a bilge pump mounting pad we recom- mend that you consult your boat dealer or repair facility for instructions regarding fabrication and installation of a suitable mounting pad.

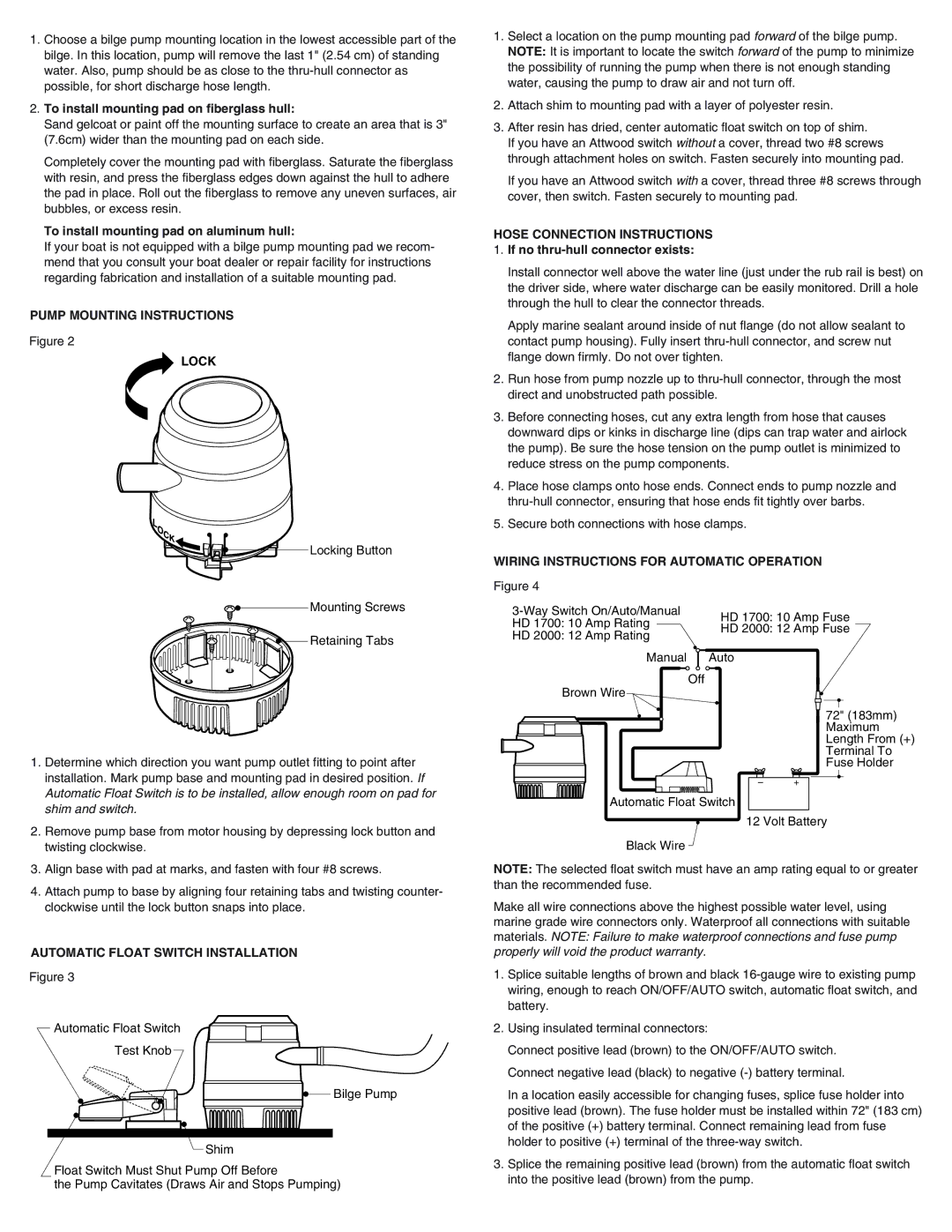

PUMP MOUNTING INSTRUCTIONS

Figure 2

LOCK

![]()

![]()

![]()

![]()

![]() ¥

¥![]()

![]() Locking Button

Locking Button

¥ | Mounting Screws |

¥ | Retaining Tabs |

1.Determine which direction you want pump outlet fitting to point after installation. Mark pump base and mounting pad in desired position. If Automatic Float Switch is to be installed, allow enough room on pad for shim and switch.

2.Remove pump base from motor housing by depressing lock button and twisting clockwise.

3.Align base with pad at marks, and fasten with four #8 screws.

4.Attach pump to base by aligning four retaining tabs and twisting counter- clockwise until the lock button snaps into place.

AUTOMATIC FLOAT SWITCH INSTALLATION

Figure 3

Automatic Float Switch

| Test Knob |

|

|

¥ | ¥ | ¥ | Bilge Pump |

|

|

¥ | ¥ |

|

Shim

Float Switch Must Shut Pump Off Before

the Pump Cavitates (Draws Air and Stops Pumping)

1.Select a location on the pump mounting pad forward of the bilge pump. NOTE: It is important to locate the switch forward of the pump to minimize the possibility of running the pump when there is not enough standing water, causing the pump to draw air and not turn off.

2.Attach shim to mounting pad with a layer of polyester resin.

3.After resin has dried, center automatic float switch on top of shim.

If you have an Attwood switch without a cover, thread two #8 screws through attachment holes on switch. Fasten securely into mounting pad.

If you have an Attwood switch with a cover, thread three #8 screws through cover, then switch. Fasten securely to mounting pad.

HOSE CONNECTION INSTRUCTIONS

1.If no thru-hull connector exists:

Install connector well above the water line (just under the rub rail is best) on the driver side, where water discharge can be easily monitored. Drill a hole through the hull to clear the connector threads.

Apply marine sealant around inside of nut flange (do not allow sealant to contact pump housing). Fully insert

2.Run hose from pump nozzle up to

3.Before connecting hoses, cut any extra length from hose that causes downward dips or kinks in discharge line (dips can trap water and airlock the pump). Be sure the hose tension on the pump outlet is minimized to reduce stress on the pump components.

4.Place hose clamps onto hose ends. Connect ends to pump nozzle and

5.Secure both connections with hose clamps.

WIRING INSTRUCTIONS FOR AUTOMATIC OPERATION

Figure 4

| HD 1700: 10 Amp Fuse | ||||

HD 1700: 10 Amp Rating |

|

| |||

|

| HD 2000: 12 Amp Fuse | |||

HD 2000: 12 Amp Rating |

|

| |||

| ¥ |

|

|

| |

Manual | Auto |

|

| ||

¥ |

|

| |||

| ¥ | ¥ | ¥ |

|

|

Brown Wire | Off |

|

|

| |

|

|

|

| ¥ | |

| ¥ |

| ¥ |

| ¥ |

¥ |

|

|

| 72" (183mm) | |

¥ |

|

|

| ||

|

|

|

|

| Maximum |

|

|

|

|

| Length From (+) |

|

|

|

|

| Terminal To |

|

|

|

|

| Fuse Holder |

|

|

| Ð | + | ¥ |

|

|

|

| ||

Automatic Float Switch

¥12 Volt Battery

Black Wire

NOTE: The selected float switch must have an amp rating equal to or greater than the recommended fuse.

Make all wire connections above the highest possible water level, using marine grade wire connectors only. Waterproof all connections with suitable materials. NOTE: Failure to make waterproof connections and fuse pump properly will void the product warranty.

1.Splice suitable lengths of brown and black

2.Using insulated terminal connectors:

Connect positive lead (brown) to the ON/OFF/AUTO switch. Connect negative lead (black) to negative

In a location easily accessible for changing fuses, splice fuse holder into positive lead (brown). The fuse holder must be installed within 72" (183 cm) of the positive (+) battery terminal. Connect remaining lead from fuse holder to positive (+) terminal of the

3.Splice the remaining positive lead (brown) from the automatic float switch into the positive lead (brown) from the pump.