General Information

Feed Rate/Chips

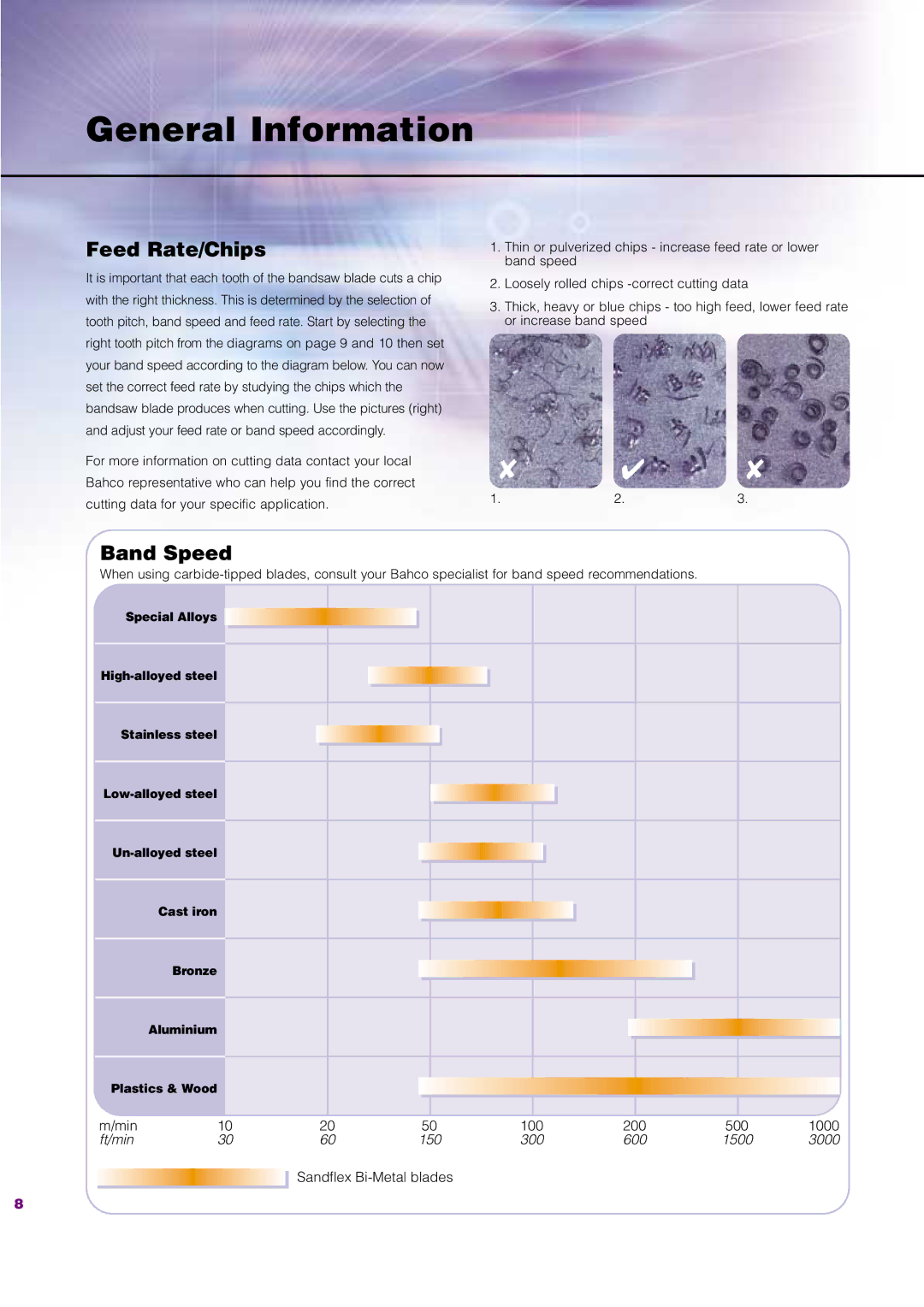

It is important that each tooth of the bandsaw blade cuts a chip with the right thickness. This is determined by the selection of tooth pitch, band speed and feed rate. Start by selecting the right tooth pitch from the diagrams on page 9 and 10 then set your band speed according to the diagram below. You can now set the correct feed rate by studying the chips which the bandsaw blade produces when cutting. Use the pictures (right) and adjust your feed rate or band speed accordingly.

For more information on cutting data contact your local Bahco representative who can help you find the correct cutting data for your specific application.

1.Thin or pulverized chips - increase feed rate or lower band speed

2.Loosely rolled chips

3.Thick, heavy or blue chips - too high feed, lower feed rate or increase band speed

✘ ✔ ✘

1.2.3.

Band Speed

When using

Special Alloys

Stainless steel

Cast iron

Bronze

Aluminium

Plastics & Wood

m/min | 10 | 20 | 50 | 100 | 200 | 500 | 1000 |

ft/min | 30 | 60 | 150 | 300 | 600 | 1500 | 3000 |

Sandflex

8