Section 4 • Bilge & Underwater Gear

C.Impact to Stern Drive

The stern drive can be damaged by impact, either while trailering or boating. To minimize the possibility of impact damage while trailering, keep the stern drive raised to the trailering position.

The hydraulic system used to raise and lower the stern drive can cushion impact and lessen damage from

If you strike a submerged object, STOP THE ENGINE as soon as possible and examine the stern drive unit for damage. Even if no damage is visible, there could be internal problems or difficulty maneuvering. If you must use the boat after impact, run at the lowest speed possible.

D.Propeller Removal and Installation

!WARNING

If engine is started during propeller maintenance, serious personal injury can occur.

Shut off engine, remove key, shift into neutral, and put tape over ignition switch key slot.

a.Shut off engine, remove key, shift into neutral and put tape over ignition switch key slot.

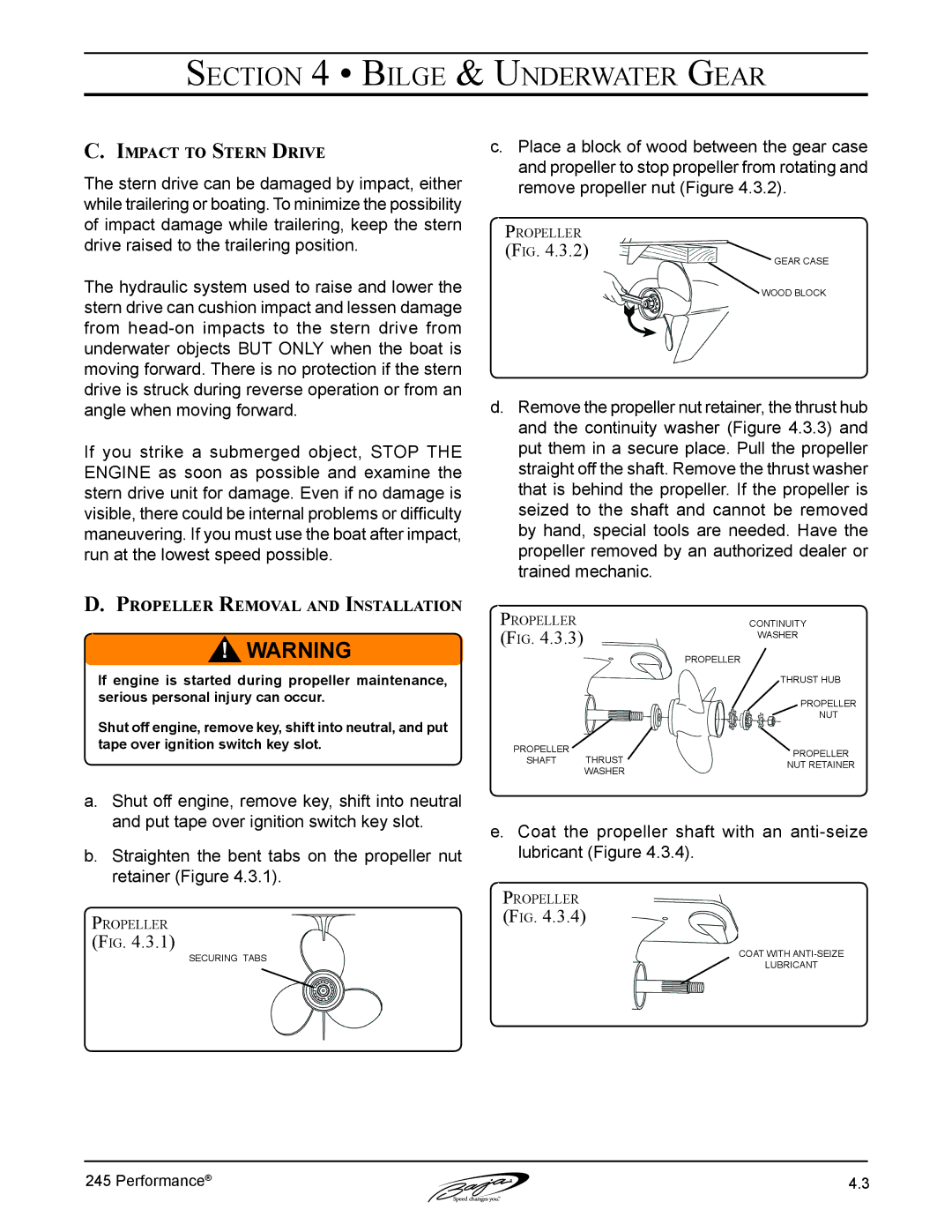

b.Straighten the bent tabs on the propeller nut retainer (Figure 4.3.1).

Propeller

(Fig. 4.3.1)

securing tabs

c.Place a block of wood between the gear case and propeller to stop propeller from rotating and remove propeller nut (Figure 4.3.2).

Propeller

(Fig. 4.3.2)

gear case

wood block

d.Remove the propeller nut retainer, the thrust hub and the continuity washer (Figure 4.3.3) and put them in a secure place. Pull the propeller straight off the shaft. Remove the thrust washer that is behind the propeller. If the propeller is seized to the shaft and cannot be removed by hand, special tools are needed. Have the propeller removed by an authorized dealer or trained mechanic.

Propeller |

| continuity | |

(Fig. 4.3.3) |

| washer | |

|

| ||

|

| propeller | |

|

| thrust hub | |

|

| propeller | |

|

| nut | |

propeller | thrust | propeller | |

shaft | |||

nut retainer | |||

| washer | ||

|

|

e.Coat the propeller shaft with an

Propeller

(Fig. 4.3.4)

coat with

lubricant

245 Performance® | 4.3 |