21

2.Direct vented – Take a draft reading from the inspection port of the boiler. This

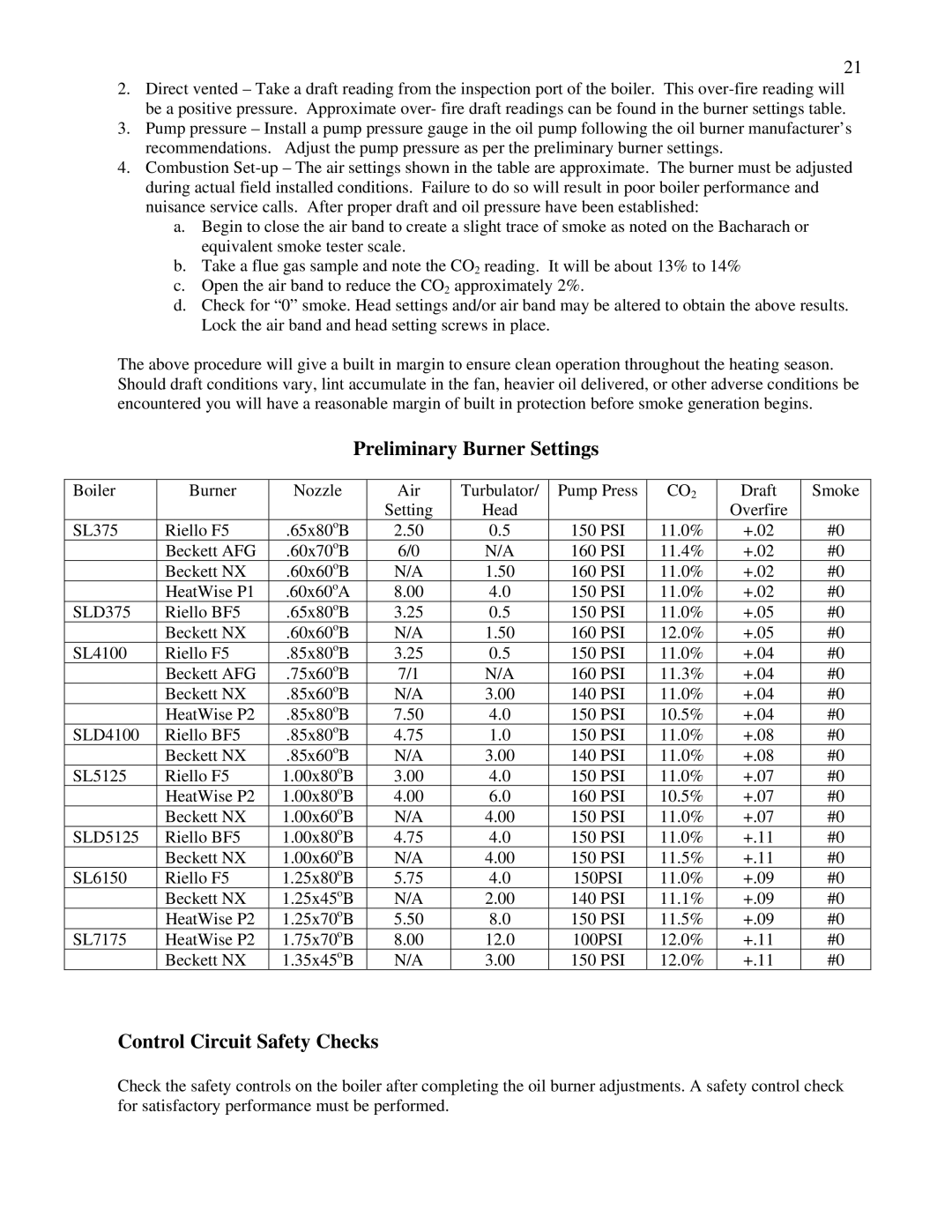

3.Pump pressure – Install a pump pressure gauge in the oil pump following the oil burner manufacturer’s recommendations. Adjust the pump pressure as per the preliminary burner settings.

4.Combustion

a.Begin to close the air band to create a slight trace of smoke as noted on the Bacharach or equivalent smoke tester scale.

b.Take a flue gas sample and note the CO2 reading. It will be about 13% to 14%

c.Open the air band to reduce the CO2 approximately 2%.

d.Check for “0” smoke. Head settings and/or air band may be altered to obtain the above results. Lock the air band and head setting screws in place.

The above procedure will give a built in margin to ensure clean operation throughout the heating season. Should draft conditions vary, lint accumulate in the fan, heavier oil delivered, or other adverse conditions be encountered you will have a reasonable margin of built in protection before smoke generation begins.

Preliminary Burner Settings

Boiler | Burner | Nozzle | Air | Turbulator/ | Pump Press | CO2 | Draft | Smoke |

|

|

| Setting | Head |

|

| Overfire |

|

SL375 | Riello F5 | .65x80oB | 2.50 | 0.5 | 150 PSI | 11.0% | +.02 | #0 |

| Beckett AFG | .60x70oB | 6/0 | N/A | 160 PSI | 11.4% | +.02 | #0 |

| Beckett NX | .60x60oB | N/A | 1.50 | 160 PSI | 11.0% | +.02 | #0 |

| HeatWise P1 | .60x60oA | 8.00 | 4.0 | 150 PSI | 11.0% | +.02 | #0 |

SLD375 | Riello BF5 | .65x80oB | 3.25 | 0.5 | 150 PSI | 11.0% | +.05 | #0 |

| Beckett NX | .60x60oB | N/A | 1.50 | 160 PSI | 12.0% | +.05 | #0 |

SL4100 | Riello F5 | .85x80oB | 3.25 | 0.5 | 150 PSI | 11.0% | +.04 | #0 |

| Beckett AFG | .75x60oB | 7/1 | N/A | 160 PSI | 11.3% | +.04 | #0 |

| Beckett NX | .85x60oB | N/A | 3.00 | 140 PSI | 11.0% | +.04 | #0 |

| HeatWise P2 | .85x80oB | 7.50 | 4.0 | 150 PSI | 10.5% | +.04 | #0 |

SLD4100 | Riello BF5 | .85x80oB | 4.75 | 1.0 | 150 PSI | 11.0% | +.08 | #0 |

| Beckett NX | .85x60oB | N/A | 3.00 | 140 PSI | 11.0% | +.08 | #0 |

SL5125 | Riello F5 | 1.00x80oB | 3.00 | 4.0 | 150 PSI | 11.0% | +.07 | #0 |

| HeatWise P2 | 1.00x80oB | 4.00 | 6.0 | 160 PSI | 10.5% | +.07 | #0 |

| Beckett NX | 1.00x60oB | N/A | 4.00 | 150 PSI | 11.0% | +.07 | #0 |

SLD5125 | Riello BF5 | 1.00x80oB | 4.75 | 4.0 | 150 PSI | 11.0% | +.11 | #0 |

| Beckett NX | 1.00x60oB | N/A | 4.00 | 150 PSI | 11.5% | +.11 | #0 |

SL6150 | Riello F5 | 1.25x80oB | 5.75 | 4.0 | 150PSI | 11.0% | +.09 | #0 |

| Beckett NX | 1.25x45oB | N/A | 2.00 | 140 PSI | 11.1% | +.09 | #0 |

| HeatWise P2 | 1.25x70oB | 5.50 | 8.0 | 150 PSI | 11.5% | +.09 | #0 |

SL7175 | HeatWise P2 | 1.75x70oB | 8.00 | 12.0 | 100PSI | 12.0% | +.11 | #0 |

| Beckett NX | 1.35x45oB | N/A | 3.00 | 150 PSI | 12.0% | +.11 | #0 |

Control Circuit Safety Checks

Check the safety controls on the boiler after completing the oil burner adjustments. A safety control check for satisfactory performance must be performed.