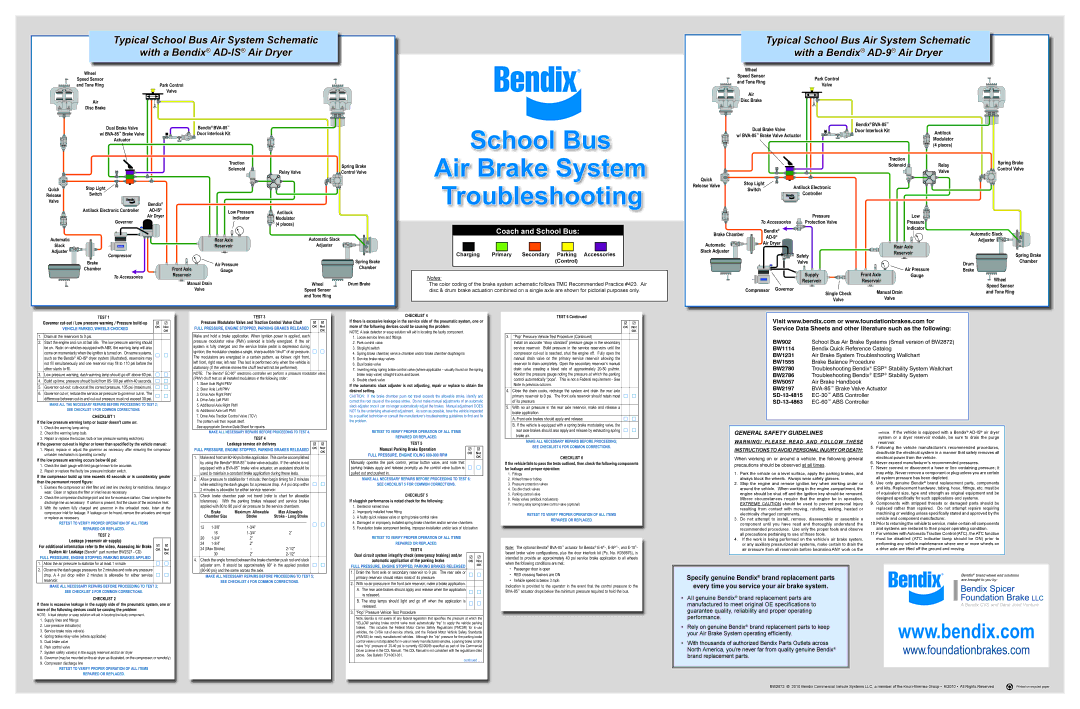

Typical School Bus Air System Schematic |

| TypicalTypical SchoolSchool BusBus AirAir SystemSystem SchematicSchematic |

with a Bendix® |

| withwith aa BendixBendix®® |

|

|

|

Wheel |

| Wheel |

| |

| Speed Sensor | Park Control | ||

Speed Sensor |

| |||

| and Tone Ring | |||

and Tone Ring | Park Control | Valve | ||

| ||||

| Valve | Air |

| |

|

|

| ||

Air |

| Disc Brake |

| |

|

|

| ||

Disc Brake |

|

|

|

| Dual Brake Valve |

|

| Bendix® |

|

| School Bus |

|

| Dual Brake Valve |

| Bendix® |

|

|

| ||||||

|

|

|

|

|

|

|

| Door Interlock Kit | Antilock |

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

| w/ |

|

| Door Interlock Kit |

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| w/ |

|

|

|

| ||||||

| Actuator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Modulator |

|

|

|

|

|

|

|

|

| Air Brake System |

|

|

|

|

|

|

| (4 places) |

|

| ||||

|

|

|

| Traction | C |

| Quick |

| Stop Light |

|

|

| Traction |

|

| Spring Brake | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| Spring Brake |

|

|

|

|

|

|

|

|

|

|

| Solenoid | Relay |

| ||

|

|

|

| Solenoid |

|

|

|

|

|

|

|

|

|

|

|

|

| Control Valve | |||

|

|

|

| Relay Valve | Control Valve |

|

|

|

|

|

|

|

|

|

|

|

| Valve |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C |

|

| |||

|

|

|

|

|

|

| Troubleshooting |

|

|

|

|

|

|

|

|

| |||||

| Antilock Electronic Controller |

| Low Pressure | Antilock |

| Release Valve |

|

|

| Antilock Electronic |

|

|

|

|

| ||||||

Quick | Stop Light |

|

|

|

|

|

|

|

|

|

|

|

| Switch |

|

|

|

|

|

| |

Release | Switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Controller |

|

|

|

|

|

Valve |

| Bendix® |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| Air Dryer |

| Indicator | Modulator |

|

|

|

|

|

|

|

|

|

| Pressure |

| Low |

|

|

|

| Governor |

|

|

|

|

|

|

|

|

|

| To Accessories | Protection Valve |

| Pressure |

|

|

| |||

|

|

|

| (4 places) |

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| Coach and School Bus: |

|

|

|

|

|

|

| Indicator |

|

|

| |||

|

|

|

|

|

|

|

|

| Brake Chamber | Bendix® |

|

|

| Automatic Slack | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Automatic |

|

|

| Rear Axle | Automatic Slack |

|

|

|

|

|

|

|

|

|

|

|

|

| Adjuster | ||

|

|

|

|

|

|

|

|

| Automatic |

| Air Dryer |

|

|

|

|

| |||||

Slack | Bendix |

|

| Reservoir | Adjuster |

|

|

|

|

|

|

|

|

| Rear Axle |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

Adjuster | Compressor |

|

|

|

|

| Charging | Primary | Secondary | Parking | Accessories | Slack Adjuster |

|

|

| Safety |

| Reservoir |

|

| Spring Brake |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

| Brake |

|

| Air Pressure |

| Spring Brake |

|

|

| (Control) |

|

|

|

|

| Valve |

|

|

| Drum | Chamber |

|

|

|

| Chamber |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Chamber |

| Front Axle | Gauge |

|

|

|

|

|

|

|

|

|

|

|

| Air Pressure |

| Brake |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| Supply | Front Axle |

|

| |||||

| To Accessories |

| Reservoir |

|

|

| Notes: |

|

|

|

|

|

|

|

| Gauge |

|

| Wheel | ||

|

| Manual Drain |

|

|

|

|

|

|

|

|

|

| Reservoir | Reservoir |

|

|

| ||||

|

|

| Wheel | Drum Brake | The color coding of the brake system schematic follows TMC Recommended Practice #423. Air |

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

| Governor |

|

|

|

| Speed Sensor | ||||||||||

|

|

|

| Valve | Speed Sensor |

| disc & drum brake actuation combined on a single axle are shown for pictorial purposes only. |

|

| Compressor | Manual Drain |

|

| and Tone Ring | |||||||

|

|

|

|

| and Tone Ring |

|

|

|

|

|

|

|

|

|

| Single Check |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Valve |

| Valve |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

TEST 1 |

|

|

Governor | | |

VEHICLE PARKED, WHEELS CHOCKED | OK | Not |

| OK | |

|

|

1.Drain all the reservoirs to 0 psi.

2.Start the engine and run at fast idle. The low pressure warning should be on. Note: on vehicles equipped with ABS, the warning lamp will also come on momentarily when the ignition is turned on. On some systems, such as the Bendix®

3. | Low pressure warning; dash warning lamp should go off above 60 psi. |

|

|

|

|

|

|

|

|

|

|

4. | Build up time; pressure should build from |

|

|

|

|

|

| ||||

|

|

|

|

|

|

5. | Governor |

|

|

|

|

|

|

6.Governor

MAKE ALL THE NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 2;

SEE CHECKLIST 1 FOR COMMON CORRECTIONS.

CHECKLIST 1

If the low pressure warning lamp or buzzer doesn’t come on:

TEST 3 |

|

|

Pressure Modulator Valve and Traction Control Valve Chuff | | |

FULL PRESSURE, ENGINE STOPPED, PARKING BRAKES RELEASED | OK | Not |

|

| OK |

Make and hold a brake application. When ignition power is applied, each pressure modulator valve (PMV) solenoid is briefly energized. If the air system is fully charged and the service brake pedal is depressed during ignition, the modulator creates a single, sharp audible “chuff” of air pressure. The modulators are energized in a certain pattern, as follows: right front, left front, right rear, left rear. This test is performed only when the vehicle is stationary (if the vehicle moves the chuff test will not be performed).

NOTE: The Bendix®

1. | Steer Axle Right PMV |

2. | Steer Axle Left PMV |

3. | Drive Axle Right PMV |

4. | Drive Axle Left PMV |

5. | Additional Axle Right PMV |

6. | Additional Axle Left PMV |

7. | Drive Axle Traction Control Valve (TCV) |

The pattern will then repeat itself. | |

CHECKLIST 4

If there is excessive leakage in the service side of the pneumatic system, one or more of the following devices could be causing the problem:

NOTE: A leak detector or soap solution will aid in locating the faulty component.

1.Loose service lines and fittings

2.Park control valve

3.Stoplight switch

4.Spring brake chamber, service chamber and/or brake chamber diaphragms

5.Service brake relay valves

6.Dual brake valve

7.Inverting relay spring brake control valve (where applicable – usually found on the spring brake relay valve) straight trucks and buses

8.Double check valve

If the automatic slack adjuster is not adjusting, repair or replace to obtain the desired setting.

CAUTION: If the brake chamber push rod travel exceeds the allowable stroke, identify and correct the root cause of the excess stroke. Do not make manual adjustments of an automatic slack adjuster once it can no longer automatically adjust the brakes. Manual adjustment DOES NOT fix the underlying

TEST 6 Continued

OK Not

OK

3.“Pop” Pressure Vehicle Test Procedure (Continued)

Install an accurate “shop standard” pressure gauge in the secondary service reservoir. Build pressure in the service reservoirs until the compressor

4.Close the drain cocks, recharge the system and drain the rear axle

primary reservoir to 0 psi. The front axle reservoir should retain most of its pressure.

5.With no air pressure in the rear axle reservoir, make and release a brake application.

A. Front axle brakes should apply and release.

B. If the vehicle is equipped with a spring brake modulating valve, the

Visit www.bendix.com or www.foundationbrakes.com for Service Data Sheets and other literature such as the following:

BW902 School Bus Air Brake Systems (Small version of BW2872)

BW1114 Bendix Quick Reference Catalog

BW1231 Air Brake System Troubleshooting Wallchart

BW1555 Brake Balance Procedure

BW2780 Troubleshooting Bendix® ESP® Stability System Wallchart

BW2786 Troubleshooting Bendix® ESP® Stability System

BW5057 Air Brake Handbook

BW2197

1.Check the warning lamp wiring.

2.Check the warning lamp bulb.

3.Repair or replace the buzzer, bulb or low pressure warning switch(es).

If the governor

1.Repair, replace or adjust the governor as necessary after ensuring the compressor unloader mechanism is operating correctly.

If the low pressure warning occurs below 60 psi:

1.Check the dash gauge with test gauge known to be accurate.

2.Repair or replace the faulty low pressure indicator switch.

If the compressor build up time exceeds 40 seconds or is considerably greater than the permanent record figure:

1.Examine the compressor air inlet filter and inlet line checking for restrictions, damage or wear. Clean or replace the filter or inlet line as necessary.

2.Check the compressor discharge port and line for excessive carbon. Clean or replace the discharge line as necessary. If carbon is present, find the cause of the excessive heat.

3.With the system fully charged and governor in the unloaded mode, listen at the compressor inlet for leakage. If leakage can be heard, remove the unloaders and repair or replace as necessary.

RETEST TO VERIFY PROPER OPERATION OF ALL ITEMS

REPAIRED OR REPLACED.

| TEST 2 |

|

|

|

|

|

|

| Leakage (reservoir air supply) | | | ||||

For additional information refer to the video, Assessing Air Brake | |||||||

| System Air Leakage (Bendix® part number BW2327 - CD) | OK | Not | ||||

|

|

|

| OK | |||

FULL PRESSURE, ENGINE STOPPED, PARKING BRAKES APPLIED |

|

|

| ||||

|

|

|

|

|

| ||

1. | Allow the air pressure to stabilize for at least 1 minute. |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

2. | Observe the dash gauge pressures for 2 minutes and note any pressure |

|

|

|

|

|

|

See appropriate Service Data Sheet for repairs. |

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 4. |

TEST 4 |

|

|

Leakage service air delivery | | |

FULL PRESSURE, ENGINE STOPPED, PARKING BRAKES RELEASED | OK | Not |

|

| OK |

1.Make and hold an

2.Allow pressure to stabilize for 1 minute; then begin timing for 2 minutes

while watching the dash gauges for a pressure drop. A 4 psi drop within 2 minutes is allowable for either service reservoir.

3.Check brake chamber push rod travel (refer to chart for allowable tolerances). With the parking brakes released and service brakes applied with 80 to 90 psi of air pressure to the service chambers.

| Brake | Maximum Allowable | Max Allowable | ||||

| Chamber Size | Stroke | Stroke - Long Stroke | ||||

__________________________________________________ |

|

|

|

| |||

12 |

|

|

|

|

| ||

|

|

|

|

| |||

| 16 | 2” | |||||

20 | 2” |

|

|

|

|

| |

24 | 2” |

|

|

|

|

| |

24 (Max Stroke) | - | ||||||

| 30 | 2” | |||||

4. Check the angle formed between the brake chamber push rod and slack | |||||||

adjuster arm. It should be approximately 90° in the applied position |

|

|

|

| |||

|

| ||||||

|

| ||||||

|

|

|

|

| |||

RETEST TO VERIFY PROPER OPERATION OF ALL ITEMS

REPAIRED OR REPLACED.

TEST 5 |

|

|

Manual Parking Brake Operation | | |

FULL PRESSURE, ENGINE IDLING | OK | Not |

| OK | |

|

|

Manually operate the park control, yellow button valve, and note that parking brakes apply and release promptly as the control valve button is pulled out and pushed in.

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 6;

SEE CHECKLIST 5 FOR COMMON CORRECTIONS.

CHECKLIST 5

If sluggish performance is noted check for the following:

1.Dented or kinked lines

2.Improperly installed hose fitting

3.A faulty quick release valve or spring brake control valve

4.Damaged or improperly installed spring brake chamber and/or service chambers

5.Foundation brake component binding, improper installation and/or lack of lubrication

RETEST TO VERIFY PROPER OPERATION OF ALL ITEMS

REPAIRED OR REPLACED.

TEST 6

Dual circuit system integrity check (emergency braking) and/or | | | |

automatic application of the parking brake | |||

OK | Not | ||

FULL PRESSURE, ENGINE STOPPED, PARKING BRAKES RELEASED |

| OK |

1. Drain the front axle or secondary reservoir to 0 psi. The rear axle or |

rear axle brakes should also apply and release by exhausting spring brake air.

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING;

SEE CHECKLIST 6 FOR COMMON CORRECTIONS.

CHECKLIST 6

If the vehicle fails to pass the tests outlined, then check the following components for leakage and proper operation:

1.Fittings

2.Kinked hose or tubing

3.Pressure protection valves

4.Double check valves

5.Parking control valve

6.Relay valves (antilock modulators)

7.Inverting relay spring brake control valve (optional)

RETEST TO VERIFY PROPER OPERATION OF ALL ITEMS

REPAIRED OR REPLACED.

Note: The optional Bendix®

• Passenger door is open |

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW THESE INSTRUCTIONS TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following general precautions should be observed at all times.

1.Park the vehicle on a level surface, apply the parking brakes, and always block the wheels. Always wear safety glasses.

2.Stop the engine and remove ignition key when working under or around the vehicle. When working in the engine compartment, the engine should be shut off and the ignition key should be removed. Where circumstances require that the engine be in operation, EXTREME CAUTION should be used to prevent personal injury resulting from contact with moving, rotating, leaking, heated or electrically charged components.

3.Do not attempt to install, remove, disassemble or assemble a component until you have read and thoroughly understand the recommended procedures. Use only the proper tools and observe all precautions pertaining to use of those tools.

4.If the work is being performed on the vehicle’s air brake system, or any auxiliary pressurized air systems, make certain to drain the air pressure from all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with a Bendix®

5.Following the vehicle manufacturer’s recommended procedures, deactivate the electrical system in a manner that safely removes all electrical power from the vehicle.

6.Never exceed manufacturer’s recommended pressures.

7.Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a component or plug unless you are certain all system pressure has been depleted.

8.Use only genuine Bendix® brand replacement parts, components and kits. Replacement hardware, tubing, hose, fittings, etc. must be of equivalent size, type and strength as original equipment and be designed specifically for such applications and systems.

9.Components with stripped threads or damaged parts should be replaced rather than repaired. Do not attempt repairs requiring machining or welding unless specifically stated and approved by the vehicle and component manufacturer.

10.Prior to returning the vehicle to service, make certain all components and systems are restored to their proper operating condition.

11.For vehicles with Automatic Traction Control (ATC), the ATC function must be disabled (ATC indicator lamp should be ON) prior to performing any vehicle maintenance where one or more wheels on a drive axle are lifted off the ground and moving.

drop. A 4 psi drop within 2 minutes is allowable for either service |

reservoir. |

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 3;

SEE CHECKLIST 2 FOR COMMON CORRECTIONS.

CHECKLIST 2

If there is excessive leakage in the supply side of the pneumatic system, one or more of the following devices could be causing the problem:

NOTE: A leak detector or soap solution will aid in locating the faulty component.

1.Supply lines and fittings

2.Low pressure indicator(s)

3.Service brake relay valve(s)

4.Spring brake relay valve (where applicable)

5.Dual brake valve

6.Park control valve

7.System safety valve(s) in the supply reservoir and/or air dryer

8.Governor (may be mounted on the air dryer as illustrated, on the compressor, or remotely)

9.Compressor discharge line

RETEST TO VERIFY PROPER OPERATION OF ALL ITEMS

REPAIRED OR REPLACED.

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 5;

SEE CHECKLIST 4 FOR COMMON CORRECTIONS.

| primary reservoir should retain most of its pressure. | ||||

2. | With no air pressure in the front axle reservoir, make a brake application. | ||||

| A. The rear axle brakes should apply and release when the application |

|

|

|

|

|

|

| |||

| is released. |

|

|

|

|

|

|

| |||

| B. The stop lamps should light and go off when the application is |

|

|

|

|

|

|

| |||

| released. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

3. | “Pop” Pressure Vehicle Test Procedure | ||||

Note: Bendix is not aware of any federal legislation that specifies the pressure at which the YELLOW parking brake control valve must automatically “trip” to apply the vehicle parking brakes. This includes the Federal Motor Carrier Safety Regulations (FMCSR) for

continued . . .

• | RED crossing flashers are ON |

• | Vehicle speed is below 3 mph |

Indication is provided to the operator in the event that the control pressure to the

Specify genuine Bendix® brand replacement parts every time you service your air brake system.

•All genuine Bendix® brand replacement parts are manufactured to meet original OE specifications to guarantee quality, reliability and proper operating performance.

•Rely on genuine Bendix® brand replacement parts to keep your Air Brake System operating efficiently.

•With thousands of authorized Bendix Parts Outlets across North America, you’re never far from quality genuine Bendix® brand replacement parts.

www.bendix.com

www.foundationbrakes.com

BW2872 © 2010 Bendix Commercial Vehicle Systems LLC, a member of the

Printed on recycled paper