CONNECTING THE AIR HOSES

Follow either Figure 4 or 5 for air hose arrangement.

1.The PuraGuard® system filter supply and delivery ports are

2.Hoses must be installed without tight turns that might cause air flow restrictions. Note: Check that the hose attachment agrees with the air flow arrow symbol (see Figure 1). The label may not be facing forward when installation is complete.

OPERATIONAL TEST

Build the air system to governor cutout. Shut off the engine. Using a soap solution, check all hoses and fittings leading to and from the PuraGuard® system filter for leakage and integrity. Repair any excessive leaks - exceeding a 1” bubble in 5 seconds - before restoring vehicle to service.

MAINTENANCE KIT INSTALLATION

KIT DESCRIPTION

The kits available allow either a filter element replacement or major overhaul of the Bendix® PuraGuard® system filter.

VEHICLE PREPARATION

1.Park the vehicle on a level surface and prevent movement by means other than the brakes.

2.Drain all reservoirs to 0 p.s.i.

3.Drain the contents of the sump into a suitable container for disposal and then

4.Using detergent and water, clean the exterior of the PuraGuard® system filter of road grime etc.

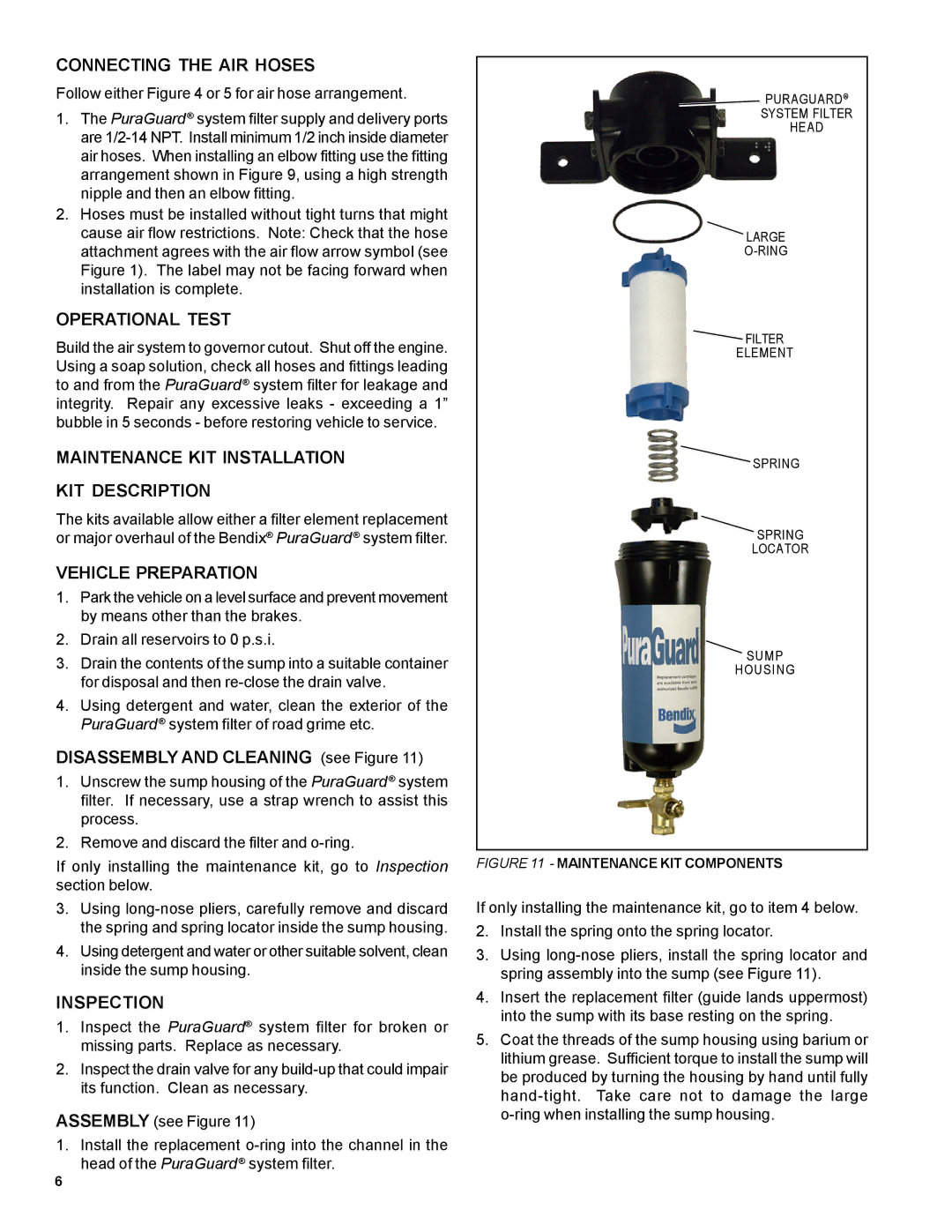

DISASSEMBLY AND CLEANING (see Figure 11)

1.Unscrew the sump housing of the PuraGuard® system filter. If necessary, use a strap wrench to assist this process.

2.Remove and discard the filter and

If only installing the maintenance kit, go to Inspection section below.

3.Using

4.Using detergent and water or other suitable solvent, clean inside the sump housing.

INSPECTION

1.Inspect the PuraGuard® system filter for broken or missing parts. Replace as necessary.

2.Inspect the drain valve for any

ASSEMBLY (see Figure 11)

1.Install the replacement

![]() PURAGUARD®

PURAGUARD®

SYSTEM FILTER

HEAD

![]() LARGE

LARGE

![]() FILTER

FILTER

ELEMENT

![]() SPRING

SPRING

![]() SPRING

SPRING

LOCATOR

![]() SUMP

SUMP

HOUSING

FIGURE 11 - MAINTENANCE KIT COMPONENTS

If only installing the maintenance kit, go to item 4 below.

2.Install the spring onto the spring locator.

3.Using

4.Insert the replacement filter (guide lands uppermost) into the sump with its base resting on the spring.

5.Coat the threads of the sump housing using barium or lithium grease. Sufficient torque to install the sump will be produced by turning the housing by hand until fully

6