PuraGuard® System |

|

|

Filter Installation System | Governor | Primary |

with Air Dryer |

| |

| Reservoir | |

| PuraGuard® |

|

| System Filter |

|

Air | Supply | Secondary |

Compressor | Reservoir | Reservoir |

FIGURE 3 | Air Dryer |

|

|

| |

|

|

|

|

|

|

PuraGuard® System Filter |

|

|

Installation System without | Governor | Primary |

Air Dryer |

| |

| Reservoir | |

| PuraGuard® |

|

| System Filter |

|

Air | Supply | Secondary |

Compressor | Reservoir | Reservoir |

FIGURE 4 |

|

|

|

|

|

The PuraGuard® system filter has two female pipe thread air connections: one supply, one delivery — identified by their relationship to the arrow symbol showing air flow on the PuraGuard® system filter top cover (see Figure 1).

Note: The PuraGuard® system filter is not recommended to be used in conjunction with an alcohol evaporator or injector. The PuraGuard® system filter will remove the liquid or aerosol alcohol introduced, defeat the purpose of the evaporator/injector and require the sump to be drained more often than normal.

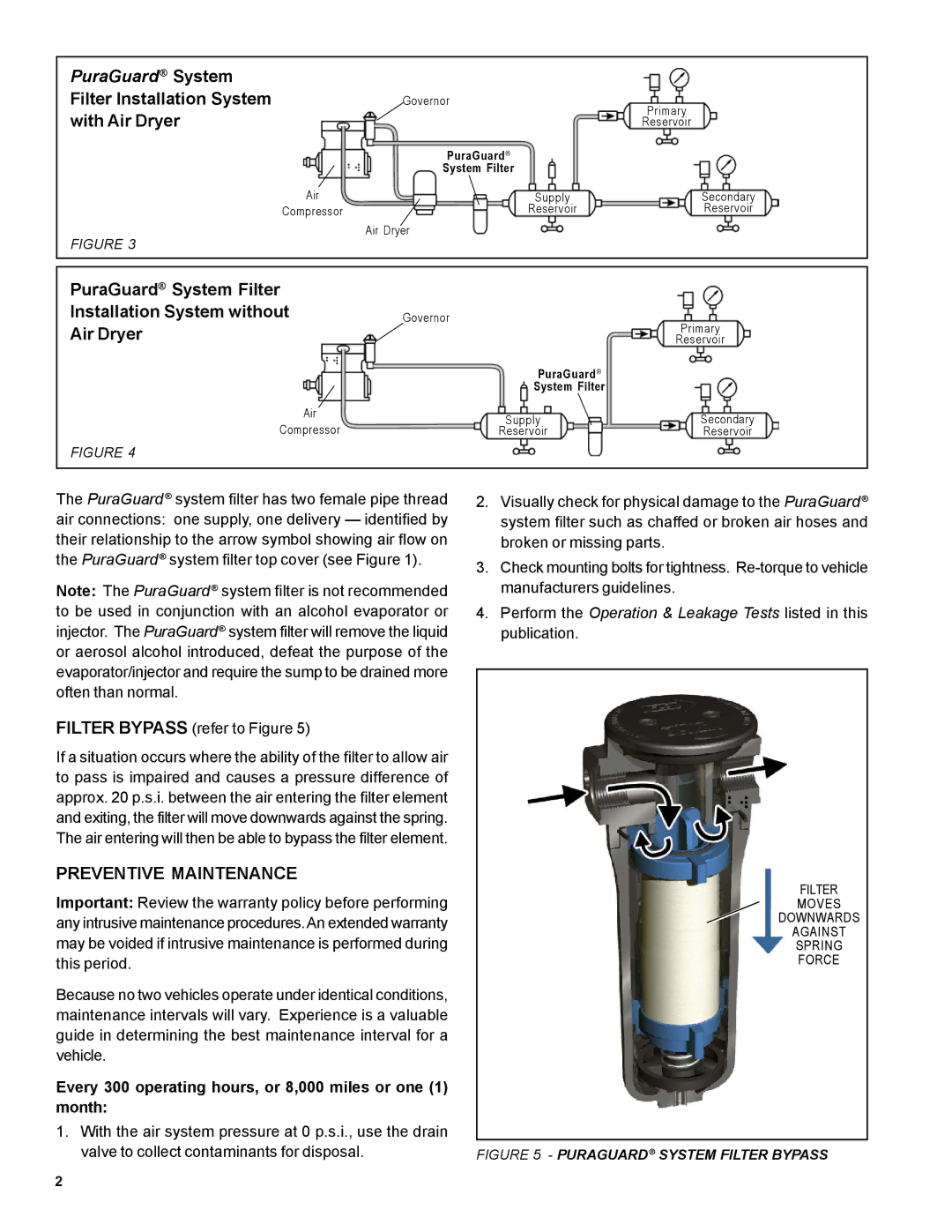

FILTER BYPASS (refer to Figure 5)

If a situation occurs where the ability of the filter to allow air to pass is impaired and causes a pressure difference of approx. 20 p.s.i. between the air entering the filter element and exiting, the filter will move downwards against the spring. The air entering will then be able to bypass the filter element.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing any intrusive maintenance procedures.An extended warranty may be voided if intrusive maintenance is performed during this period.

Because no two vehicles operate under identical conditions, maintenance intervals will vary. Experience is a valuable guide in determining the best maintenance interval for a vehicle.

Every 300 operating hours, or 8,000 miles or one (1) month:

1.With the air system pressure at 0 p.s.i., use the drain valve to collect contaminants for disposal.

2.Visually check for physical damage to the PuraGuard® system filter such as chaffed or broken air hoses and broken or missing parts.

3.Check mounting bolts for tightness.

4.Perform the Operation & Leakage Tests listed in this publication.

FILTER

MOVES

DOWNWARDS

AGAINST

SPRING

FORCE

FIGURE 5 - PURAGUARD® SYSTEM FILTER BYPASS

2