DISASSEMBLY | DISASSEMBLY |

Rotochamber from Master Cylinder FIGURE 1

1.Remove four cap screws (1), and remove the master cylinder from the rotochamber.

Rotochamber

1.Remove the Gap screws (2) which hold the rotochamber head in the shell and remove the head (6), return spring (7), and spring guide (8).

2.Remove the nuts (3) from the body which secure the outer clamp (4) to the body. On some units, one of the mounting brackets is also retained by three of these nuts.

3.Place body, open end down on bench and tap the ends of the studs (5) with a brass drift, lead or plastic hammer. The studs should be tapped on one side of the air inlet and then the other alternately, to free the outer clamp.

4.Grasp the push rod and, by pulling and wiggling the entire assembly consisting of push rod and plate, diaphragm guide, diaphragm, inner and outer clamps should ease out of the body.

5.Remove the outer clamp.

6.Remove nuts from inside of diaphragm guide.

7.Disassemble the inner diaphragm clamp, diaphragm, push plate rod assembly, and diaphragm guide.

8.Remove the stroke warning switch from the rotochamber head and bench test for electrical integrity. If OK, replace in head.

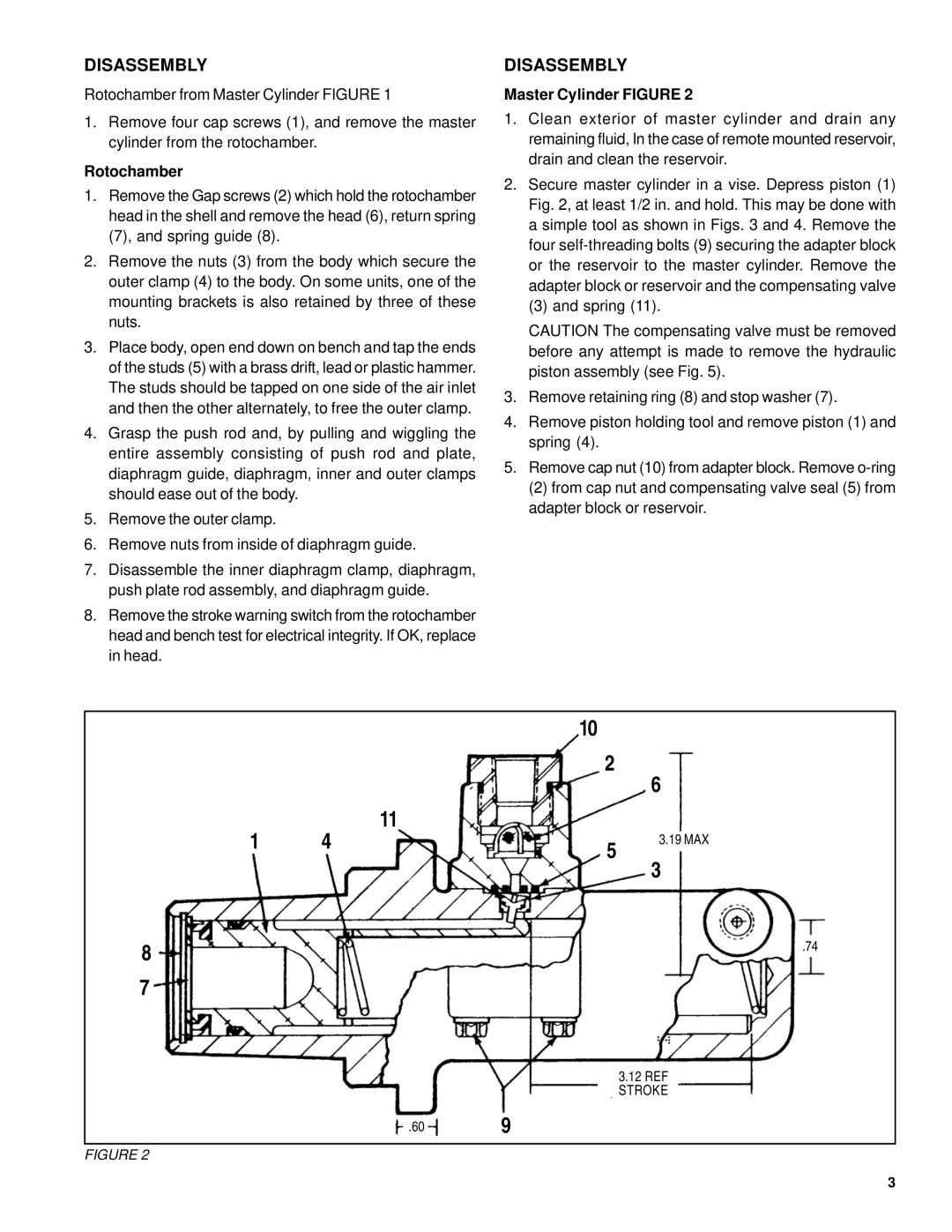

Master Cylinder FIGURE 2

1.Clean exterior of master cylinder and drain any remaining fluid, In the case of remote mounted reservoir, drain and clean the reservoir.

2.Secure master cylinder in a vise. Depress piston (1) Fig. 2, at least 1/2 in. and hold. This may be done with a simple tool as shown in Figs. 3 and 4. Remove the four

(3) and spring (11).

CAUTION The compensating valve must be removed before any attempt is made to remove the hydraulic piston assembly (see Fig. 5).

3.Remove retaining ring (8) and stop washer (7).

4.Remove piston holding tool and remove piston (1) and spring (4).

5.Remove cap nut (10) from adapter block. Remove

(2) from cap nut and compensating valve seal (5) from adapter block or reservoir.

|

| 10 |

| |

|

| 2 | 6 | |

|

|

| ||

1 | 4 | 11 | 3.19 MAX | |

5 | ||||

|

| 3 | ||

|

|

|

8 | .74 |

| |

7 |

|

3.12 REF STROKE

.609

FIGURE 2

3