6.Record the output voltage when the pedal is in the idle position (V1). Then slowly depress the pedal. When the ohm meter shows that the resistance has changed from “overload” to about .003 ohms (or from .003 ohms to “overload”), stop depressing the pedal. Record the voltage (Vx) registered with the pedal in this position. Then press the pedal to the full throttle position and record the output voltage (V2).

7.Calculate the “switch point percentage” using the formula below.

Switch point percentage =

Vx = Output voltage when the switch changed

V1 = idle voltage

V2 = full throttle voltage

DIGITAL

VOLT/

POWEROHM

SUPPLY METER

| PIN C |

RESISTOR | GROUND |

| |

TEST LOAD | PIN B |

47,000 OHM | VOUT |

| (OUTPUT) |

PIN A VREF (INPUT)

PIN A VREF (INPUT)

POTENTIOMETER

![]() POTENTIOMETER

POTENTIOMETER

PC. NO. ON THIS

SURFACE

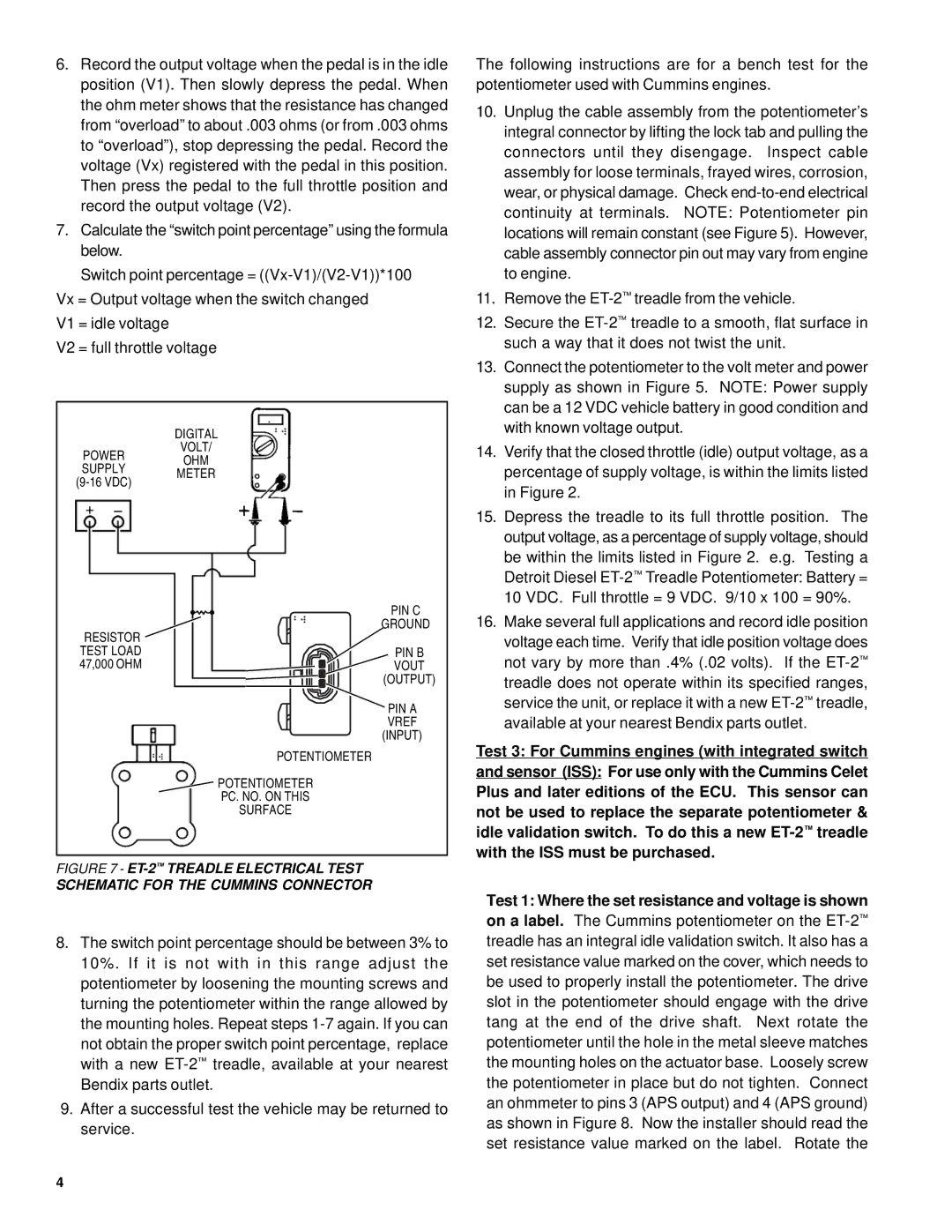

FIGURE 7 - ET-2™ TREADLE ELECTRICAL TEST

SCHEMATIC FOR THE CUMMINS CONNECTOR

8.The switch point percentage should be between 3% to 10%. If it is not with in this range adjust the potentiometer by loosening the mounting screws and turning the potentiometer within the range allowed by the mounting holes. Repeat steps

9.After a successful test the vehicle may be returned to service.

The following instructions are for a bench test for the potentiometer used with Cummins engines.

10.Unplug the cable assembly from the potentiometer’s integral connector by lifting the lock tab and pulling the connectors until they disengage. Inspect cable assembly for loose terminals, frayed wires, corrosion, wear, or physical damage. Check

11.Remove the

12.Secure the

13.Connect the potentiometer to the volt meter and power supply as shown in Figure 5. NOTE: Power supply can be a 12 VDC vehicle battery in good condition and with known voltage output.

14.Verify that the closed throttle (idle) output voltage, as a percentage of supply voltage, is within the limits listed in Figure 2.

15.Depress the treadle to its full throttle position. The output voltage, as a percentage of supply voltage, should be within the limits listed in Figure 2. e.g. Testing a Detroit Diesel

16.Make several full applications and record idle position voltage each time. Verify that idle position voltage does not vary by more than .4% (.02 volts). If the

Test 3: For Cummins engines (with integrated switch

and sensor (ISS): For use only with the Cummins Celet Plus and later editions of the ECU. This sensor can not be used to replace the separate potentiometer & idle validation switch. To do this a new

Test 1: Where the set resistance and voltage is shown on a label. The Cummins potentiometer on the

4