17 | MAINTENANCE continued |

17.1CABLE ADJUSTMENTS

CAUTION: DO NOT make cable adjustment when engine is running. Disconnect spark plug wire before making any adjustments.

Brake Adjustment

The brake control cable is spring loaded and requires no adjustment; however, the transaxle brake is adjustable. When the mower is in neutral and can

be pushed by hand without depressing the brake lever, the transaxle brake needs adjustment.

Using a ½ inch wrench turn the adjusting nut ¼ turn clockwise (see figure

With the machine in neutral and:

1.The brake lever not depressed, the brake should be on and inhibit the machine from being rolled by pushing.

2.The brake lever depressed the brake should be off and the machine should roll uninhibited by the brake.

Figure

Transaxle Drive Control Cable Adjustment

When the transaxle drive belt slips, the drive control cable needs to be adjusted or the belt needs to be replaced with a new belt.

Cable Adjustment:

1.Using a 3/8” wrench, remove the rear access door (Item 51).

2.Using a ½ “open end wrench, turn the inside adjusting nut counter- clockwise and back it off 1/8", then tighten the outboard adjusting nut against the support bracket (see figure

3.Check for proper operation. If the operation is not correct, repeat step 2.

4.Replace the access door.

The drive control cable adjustment should be the minimum amount required so the belt does not slip when the drive is engaged.

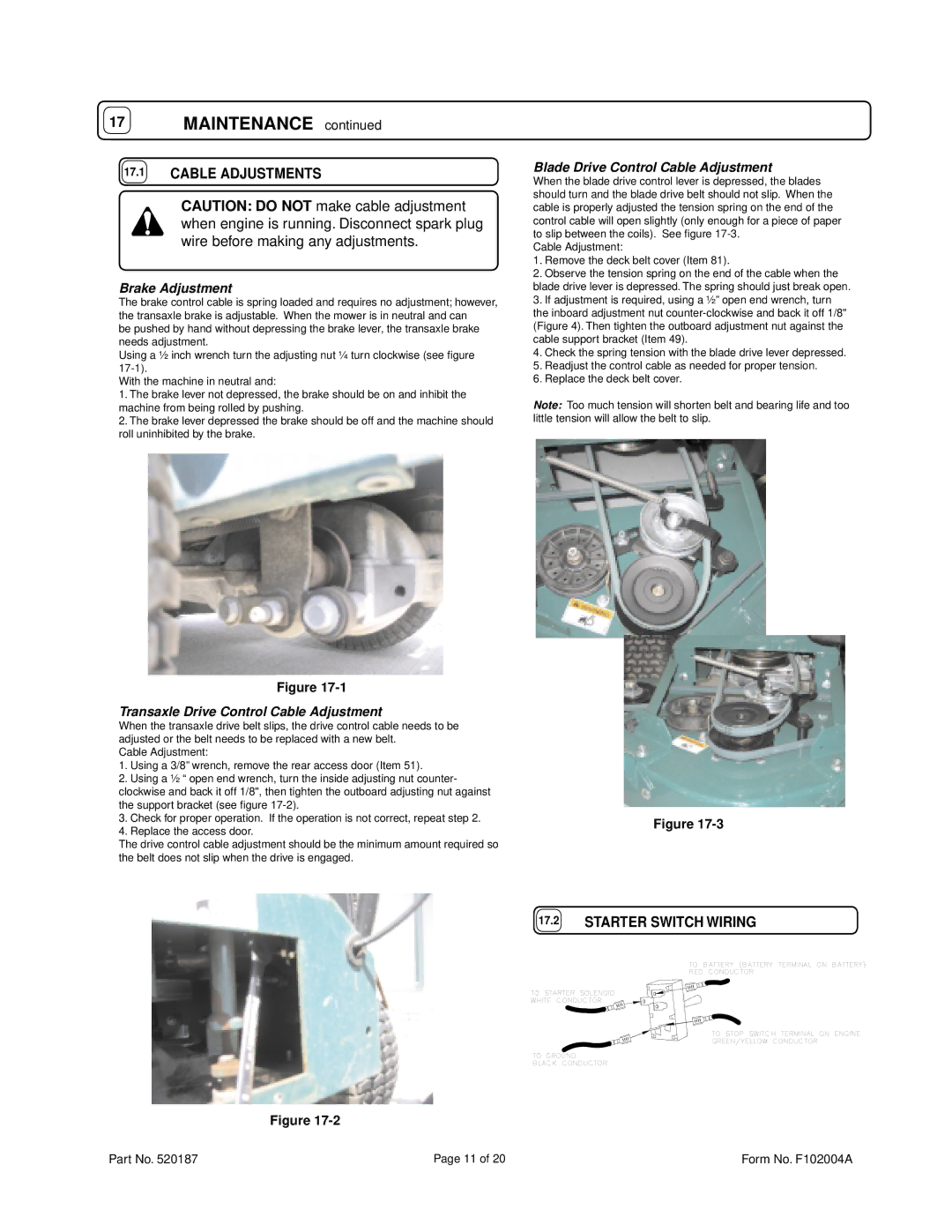

Blade Drive Control Cable Adjustment

When the blade drive control lever is depressed, the blades should turn and the blade drive belt should not slip. When the cable is properly adjusted the tension spring on the end of the control cable will open slightly (only enough for a piece of paper to slip between the coils). See figure

Cable Adjustment:

1.Remove the deck belt cover (Item 81).

2.Observe the tension spring on the end of the cable when the blade drive lever is depressed. The spring should just break open.

3.If adjustment is required, using a ½” open end wrench, turn the inboard adjustment nut

4.Check the spring tension with the blade drive lever depressed.

5.Readjust the control cable as needed for proper tension.

6.Replace the deck belt cover.

Note: Too much tension will shorten belt and bearing life and too little tension will allow the belt to slip.

Figure

17.2STARTER SWITCH WIRING

TO BATTERY (BATTERY TERMINAL ON BATTERY)

RED CONDUCTOR

TO STARTER SOLENOID

WHITE CONDUCTOR

TO STOP SWITCH TERMINAL ON ENGINE

GREEN/YELLOW CONDUCTOR

TO GROUND

BLACK CONDUCTOR

Figure

Part No. 520187 | Page 11 of 20 | Form No. F102004A |