HP3400 specifications

The Billy Goat HP3400 is a robust, high-performance lawn care machine designed for professional landscapers and homeowners who demand the best in grass and debris removal. With its powerful engine and innovative features, this machine stands out in the market for its reliability and efficiency.At the heart of the HP3400 is a reliable 3400 series engine, which offers a strong blend of power and fuel efficiency. This engine is specifically designed to provide optimal performance while minimizing emissions, making it an environmentally friendly choice. The HP3400 boasts an impressive cutting width of 34 inches, allowing users to cover larger areas in less time. This is particularly beneficial for commercial landscapers who need to maximize productivity.

One of the key features of the Billy Goat HP3400 is its unique hydrostatic drive system. This technology provides smooth acceleration and effortless control, allowing users to navigate through tough terrains without sacrificing comfort. The hydrostatic drive also enhances maneuverability, making it easy to tackle tight corners and various landscaping challenges.

The HP3400 is equipped with a heavy-duty debris bagging system, which efficiently collects grass clippings, leaves, and other debris. The large capacity bag minimizes the need for frequent emptying, enabling users to work longer without interruptions. Furthermore, the bagging system employs a patented high-lift design that ensures maximum airflow and superior collection performance.

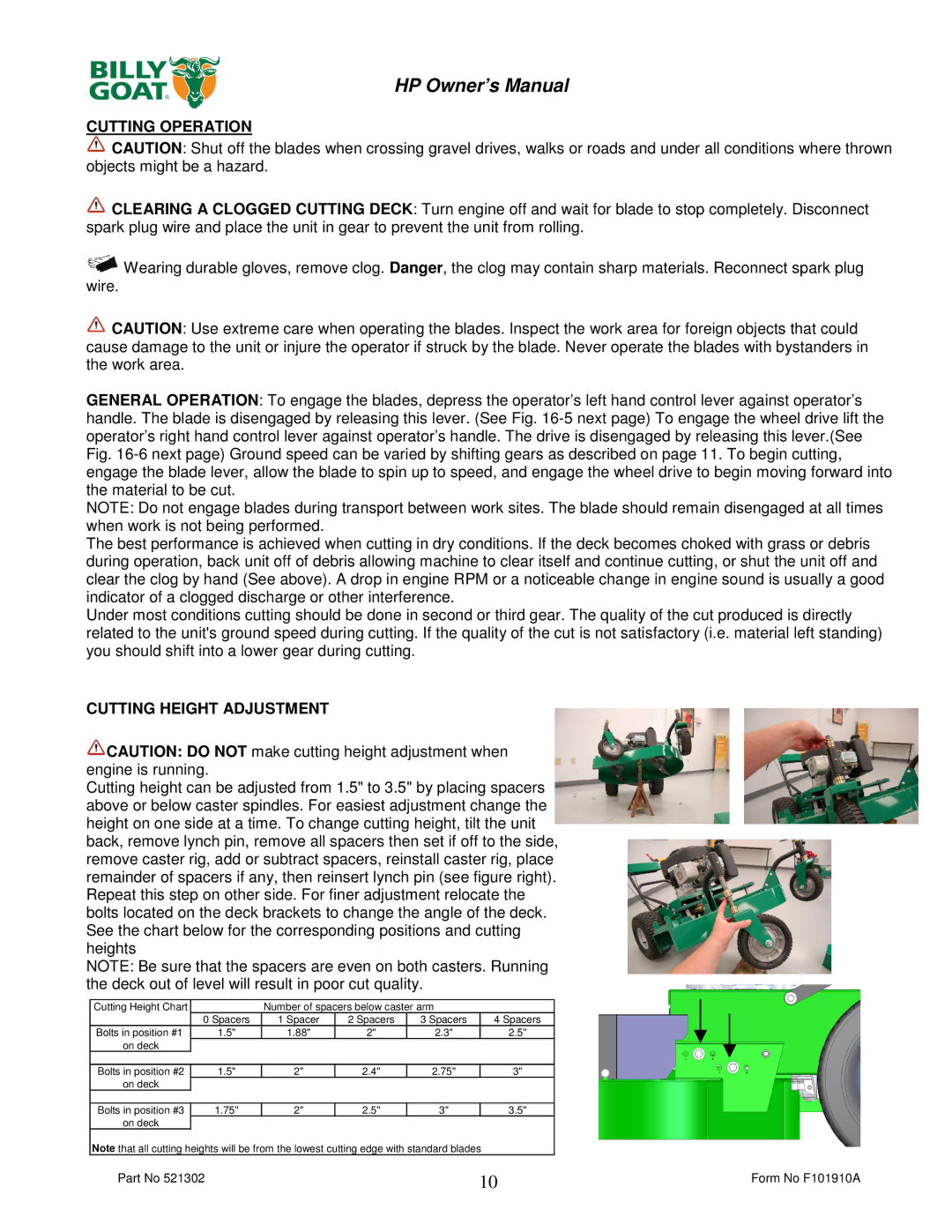

For added convenience, the Billy Goat HP3400 features an adjustable handle that caters to users of different heights, promoting ergonomic operation. The easy-to-use control panel allows for quick adjustments to speed and cutting height, ensuring that the machine can adapt to a variety of mowing conditions and grass types.

The chassis of the HP3400 is constructed from durable materials that ensure longevity even in demanding conditions. It's designed to withstand the rigors of frequent use while maintaining its performance over time.

In summary, the Billy Goat HP3400 is a top-tier lawn mower that combines power, efficiency, and user-friendly features. Whether used for commercial landscaping or residential maintenance, its advanced technologies and robust construction make it a worthwhile investment for anyone looking to achieve pristine lawn care results.