![]() WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT.

![]() WARNING: CUT HAZARD. Before cutting any type of material, be sure it is firmly anchored or clamped to prevent slipping.

WARNING: CUT HAZARD. Before cutting any type of material, be sure it is firmly anchored or clamped to prevent slipping.

![]() WARNING: CUT HAZARD. Let the tool work at its own pace. Do not overload, blade breakage may occur.

WARNING: CUT HAZARD. Let the tool work at its own pace. Do not overload, blade breakage may occur.

![]() WARNING: CUT HAZARD. This tool has no provision to lock the switch in the ON position, and should never be locked in the ON position by any other means.

WARNING: CUT HAZARD. This tool has no provision to lock the switch in the ON position, and should never be locked in the ON position by any other means.

To make a cut: |

| |

• | Clearly mark the desired cutting area. | C |

• To switch the tool on, pull the variable speed trigger on the power |

| |

| unit. The tool speed depends on how far you pull the trigger. |

|

• Switch the tool on before applying pressure and slowly feed the |

| |

| plunge cut blade into the workpiece at the marked location. |

|

| WARNING: CUT HAZARD. Ensure the blade is not in contact |

|

with cutting surface before starting saw. |

| |

• | Advance the blade along the cutting line until cut is completed. |

|

• | Don’t force the tool; let the blade cut at its own speed. |

|

To switch the tool off, release the trigger. |

| |

| NOTE: Always use the appropriate type of saw blade for the work piece material and type of cut. | |

| Cut only with sharp blades; they cut cleaner, faster and put less strain on the motor while cutting. | |

SANDING

![]() WARNING: Fire hazard. When working on metal surfaces, do not use a vacuum cleaner because sparks are generated. Wear safety glasses and a dustmask. Due to the danger of fire, do not use your sander to sand magnesium surfaces. Do not use for wet sanding.

WARNING: Fire hazard. When working on metal surfaces, do not use a vacuum cleaner because sparks are generated. Wear safety glasses and a dustmask. Due to the danger of fire, do not use your sander to sand magnesium surfaces. Do not use for wet sanding.

•To switch the tool on, pull the variable speed trigger on the power unit. The tool speed depends on how far you pull the trigger.

•To switch the tool off, release the trigger.

NOTE: Do not rest fingers on platen during use. Move it in long sweeping strokes across the surface, letting it do the work. Light pressure is all that is required for sanding. Excessive pressure will slow the tool and produce inferior results. Check your work often, product is capable of removing material rapidly. Excessive force will reduce the working efficiency and cause motor overload. Replacing the sanding sheet regularly will maintain optimum working efficiency.

NOTE: Always ensure the workpiece is firmly held or clamped to prevent movement. Any movement of the material may affect the quality of the sanding finish.

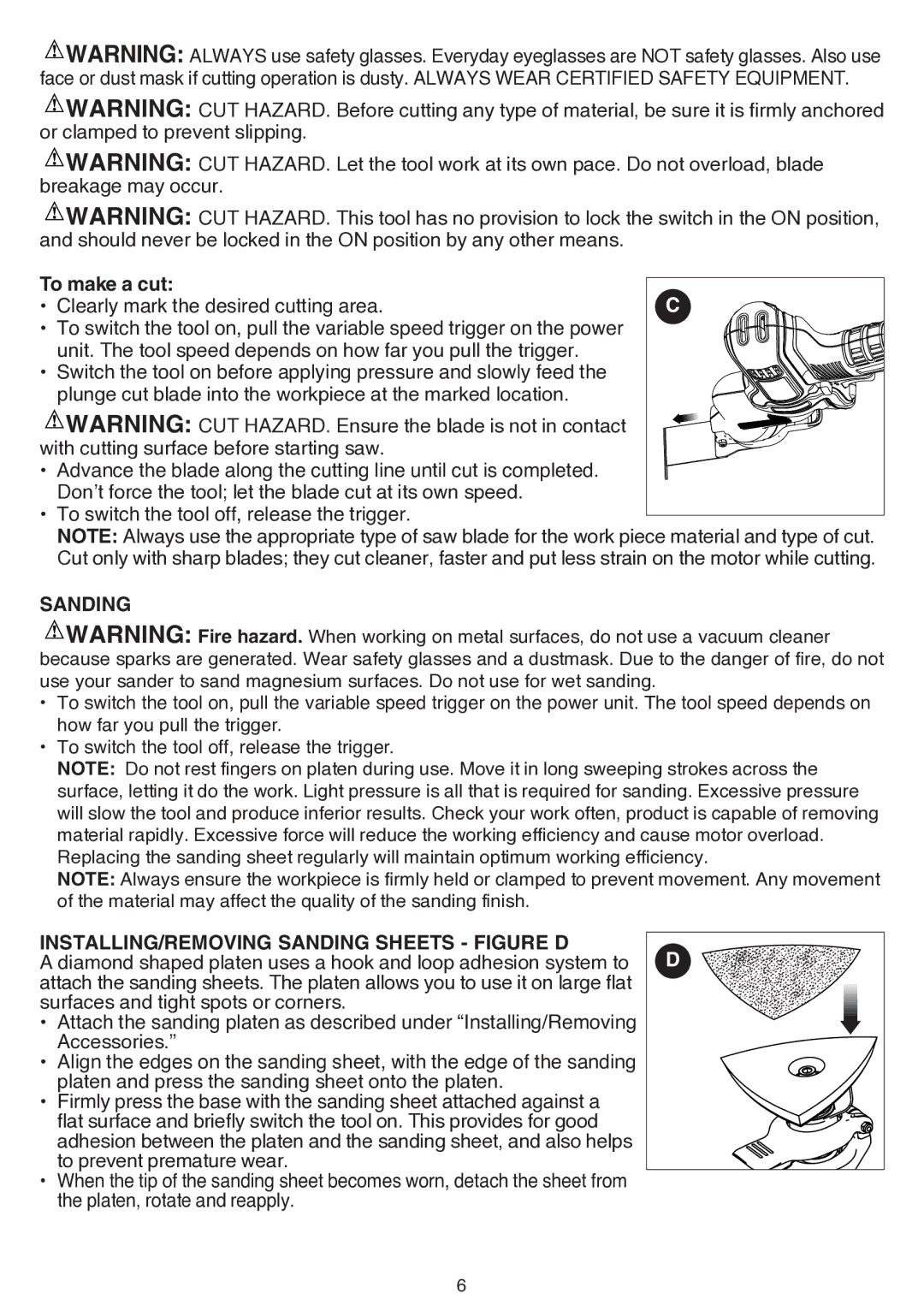

INSTALLING/REMOVING SANDING SHEETS - FIGURE D

A diamond shaped platen uses a hook and loop adhesion system to attach the sanding sheets. The platen allows you to use it on large flat surfaces and tight spots or corners.

• Attach the sanding platen as described under “Installing/Removing Accessories.”

• Align the edges on the sanding sheet, with the edge of the sanding platen and press the sanding sheet onto the platen.

• Firmly press the base with the sanding sheet attached against a flat surface and briefly switch the tool on. This provides for good adhesion between the platen and the sanding sheet, and also helps to prevent premature wear.

• When the tip of the sanding sheet becomes worn, detach the sheet from the platen, rotate and reapply.

D

6