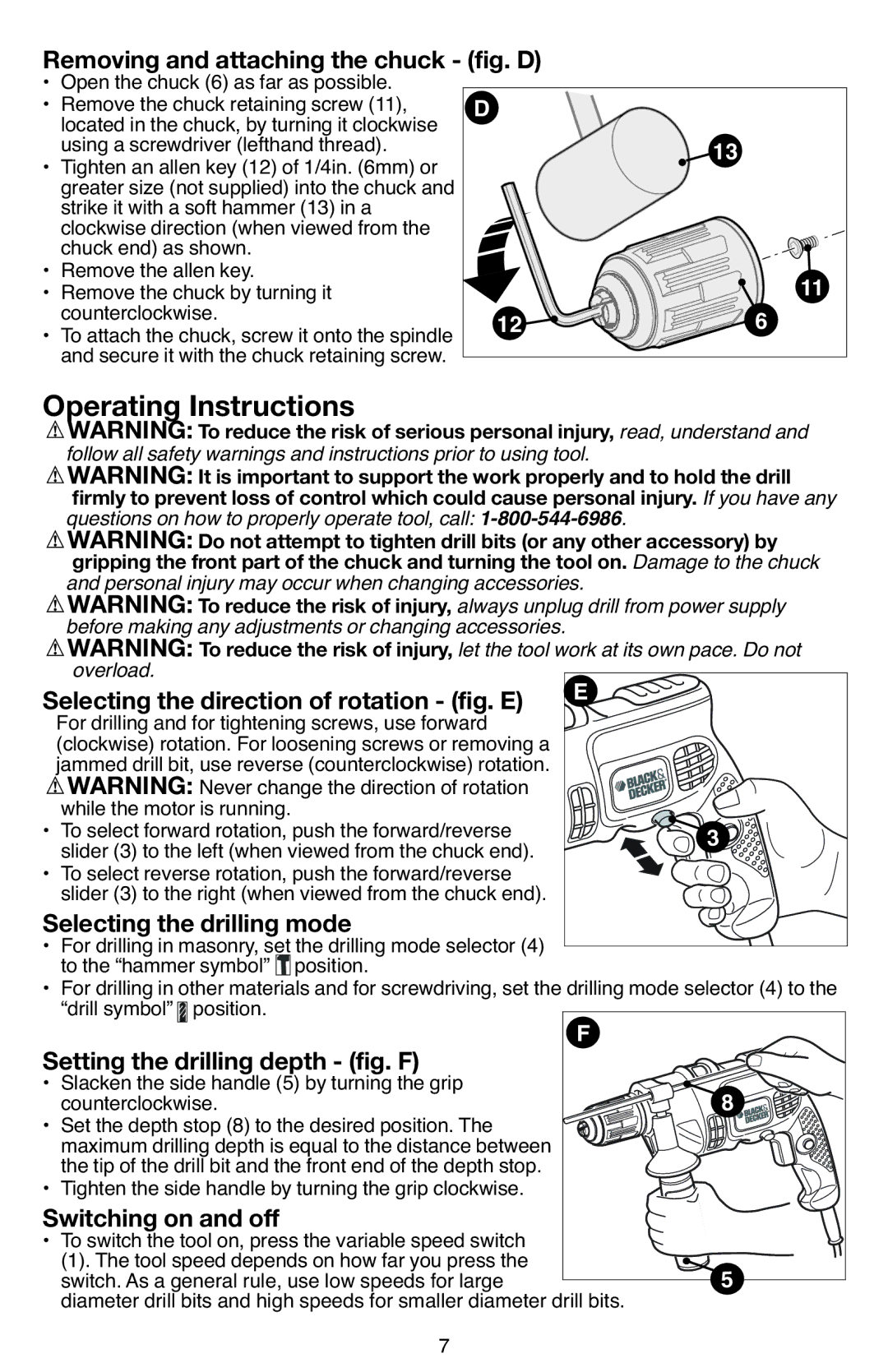

• | Open the chuck (6) as far as possible. |

|

|

|

Removing and attaching the chuck - (fig. D) |

|

| ||

• | Remove the chuck retaining screw (11), |

|

|

|

D |

|

| ||

| located in the chuck, by turning it clockwise |

|

| |

• | using a screwdriver (lefthand thread). |

| 13 |

|

Tighten an allen key (12) of 1/4in. (6mm) or |

|

| ||

| greater size (not supplied) into the chuck and |

|

|

|

| strike it with a soft hammer (13) in a |

|

|

|

| clockwise direction (when viewed from the |

|

|

|

• | chuck end) as shown. |

|

|

|

Remove the allen key. |

|

| 11 | |

• | Remove the chuck by turning it |

|

| |

• | counterclockwise. | 12 | 6 |

|

To attach the chuck, screw it onto the spindle |

| |||

| and secure it with the chuck retaining screw. |

|

|

|

|

|

|

| |

Operating Instructions |

|

| ||

| WARNING: To reduce the ri k of serious personal injury, read, understand and | |||

| follow all safety warnings and instructions prior to using tool. |

| ||

| WARNING: It is important to support the work properly and to hold the drill | |||

| questions on how to properly operate tool, |

| ||

| firmly to prevent loss of control which could cause personal injury. If you have any | |||

| gripping the front p rt of the chuck and turning the tool on. Damage to the chuck | |||

| WARNING: Do not attempt to tighten drill bits (or any other ccess ry) by | |||

| and personal injury may occur when changing accessories. |

| ||

| WARNING: To re ce the risk of i jury, always unplug drill frompower supply | |||

| before making any adjustments or changing accessories. |

|

| |

| WARNING: To reduce the risk of injury, let the tool work at itsown pace. Do not | |||

| overload. |

| E |

|

| For drilling and for tightening screws, use forward |

| ||

Selecti | the direction ofrotation - (fig. E) |

| ||

| (clockwise) rotation. For loosening screws or removing a |

|

| |

| jammed drill bit, use reverse (counterclockwise) rotation. |

|

| |

| WARNING: Never change the direction of rotation |

|

| |

• | while the motor is running. |

| 3 | |

To select forward rotation, push the forward/reverse |

| |||

| slider (3) to the left (when viewed from the chuck end). |

|

| |

• To select reverse rotation, push the forward/reverse |

|

| ||

• | slider (3) to the right (when viewed from the chuck end). |

|

| |

For drilling in masonry, set the drilling mode selector (4) |

|

| ||

Selecting the drillingmode |

|

| ||

| to the “hammer symbol” position. |

|

| |

• For drilling in other materials and forscrewdriving, set the drilling modeselector (4) to the | ||||

• | “drill symbol” position. | F |

| |

Slacken the side handle (5) by turning the grip |

| |||

Setting t | e drilling depth - (f g. F) | 8 | ||

• | counterclockwise. |

| ||

Set the depth stop (8) to the desired position. The |

|

| ||

| maximum drilling depth is equal to the distance between |

|

| |

• | the tip of the drill bit and the front end of the depth stop. |

|

| |

Tighten the side handle by turning the grip clockwise. |

|

| ||

• To switch the tool on, press the variable speed switch |

|

| ||

Switching on and off |

|

| ||

| (1). The tool speed depends on how far you press the |

| 5 | |

| switch. As a general rule, use low speeds for large |

| ||

| diameter drill bits and high speeds for smaller diameter drill bits. |

| ||

|

| 7 |

|

|