ENGLISH

GENERAL SAFETY RULES AND INSTRUCTIONS FOR ALL TOOLS

WARNING: Read and understand all instructions. Failure to follow all instructions listedSAVEbelow THESEmay result in electricINSTRUCTIONSshock, fire and/or serious personal injury.

WARNING: Read and understand all instructions. Failure to follow all instructions listedSAVEbelow THESEmay result in electricINSTRUCTIONSshock, fire and/or serious personal injury.

WorkKeepAreayour work area clean and well lit. Cluttered benches and dark areas invite

• Doaccidentsnot operate. power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

• Keepor fumesbystanders,. children, and visitors away while operating a power tool. Distractions can cause you to lose control.

Electrical• Double insulatSafetyd tools are equipped with a polarized plug (one blade is wider than the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double

Insulation

eliminates the need for the three wire grounded power cord and grounded

eliminates the need for the three wire grounded power cord and grounded

•Avoidpower bodysupplycontactsystem.with grounded surfaces such as pipes, radiators, ranges and refrigerators.

•Don’t expose Therpoweristoolsan increasedto rain orriskwetofconditionselectric shock. if your body is grounded. Water entering a power tool will

•Doincreasenot abusethe risktheofcordelectric. Nevershockuse. the cord to carry the tools or pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately

•When operating a power tool. Damagoutside,dusecordsanincreaseoutdoortheextensionrisk of electriccord markedshock. "W-A" or "W." These cords are rated for outdoor use and reduce the risk of electric shock.

Personal• Stay alert,Safetywatch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious

• Dresspersonalproperlyinjury. . Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothing, jewelry, or long

• Avoidhair canaccidentalbe caughtstartingin moving. Bepartssure. Airswitchventsiscoveroff beforemovingpluggingparts andinshould. be avoided. Carrying tools with

• Removeyour fingeradjustingon the switchkeysororpluggingwrenchesin toolsbeforethatturninghave thetheswitchtool onon. invites accidents.

A wrench or key that

• Dois leftnotattachedoverreachto a. rotatingKeep properpart offootingthe toolandmaybalanceresult inatpersonalall timesinjury. .

Proper footing and

• Usebalancesafetyenablesequipmentbetter.controlAlwaysofwearthe tooleyeinprotectionunexpected. situations.

Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

Tool• UseUseclampsandor Careother practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to

•Dolossnotof cforcentrol.tool. Use the correct tool for your application. The correct tool will do the

•Dojob betternot useandtoolsaferif switchat he ratedoesfornotwhichturnititisondesignedor off. .Any tool that cannot be controlled

•Disconnectw th the swi ctheisplugdangerousfrom theandpowermust besourcerepairedbefore. making any adjustments, changing accessories, or storing the tool. Such preventative safety measures reduce

•Storethe iskidleof startingtools outtheoftoolreacha cidentalof childreny. and other untrained persons. Tools are

•Maintaindangeroustoolsin thewithhandscareof. untrainedKeep cuttinguserstools. sharp and clean. Properly maintained

•Checktools, withforsharpmisalignmentcutting edgesor bindingare lessoflikelymovingto bindparts,andbreakageare e si roftoparts,controland. any other condition that may affect the tools operation. If damaged, have the tool serviced before using.

•Use only accessories thatManyareaccidentsrecommendedare causedby theby poorlymanufacturermaintainedfor toyourls. model. Accessories that may be suitable for one tool, may become hazardous when used on another tool.

Service• Tool service must be performed only by qualified repair personnel. Service or

•Whenmaintenanceservicingperformeda tool, useby unqualifionly identicald personnelreplacementould resultpartsin. aFollowrisk ofinstructionsinju y. in the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Specific Safety Rules | |

• Hold tool by insulated gripping surfaces when performing an operation where the |

• | cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will |

Keep hands away from cutting area. Never reach underneath the material for any |

| make expo ed metal parts of the tool "live" and shock the operator. |

| reason. Hold front of saw by grasping the contoured gripping area. Do not insert fingers or |

• | thumb into the vicinity of the reciprocating blade and blade clamp. Do not stabilize the |

Keep blades sharp. Dull blades may cause | saw to swe ve or stall under pressu e. |

| saw by gripping the shoe. | |

• | When cutting pipe or conduit ensure that they are free from water, electrical wiring, |

| etc. | |

| WARNING: Some dust created by power sanding, sawing, grinding, drilling, and |

| other construction activities contains chemicals known to cause cancer, birth |

| defects or other reproductive harm. Some examples of these chemicals are: |

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

•Avoiddesignedprolongedto filter outcontactmicroscopicwith dustparticlesfrom. power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promoteWARNING:absorptionUse ofofthisharmfultool canhemicalsgenerate. and/or disperse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles

awayCAUTION:from facWearandappropriatebody. hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

awayCAUTION:from facWearandappropriatebody. hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

The label on your tool may include the following symbols.

V | volts | A | amperes |

Hz | hertz | W | watts |

min | ............minutes | no | alternating current |

| direct current | no load speed |

|

| ............Class II Construction | | | .......... | earthing terminal |

| | | |

.............. | safety alert symbol | .../min | revolutions or |

| | | | | reciprocations per minute |

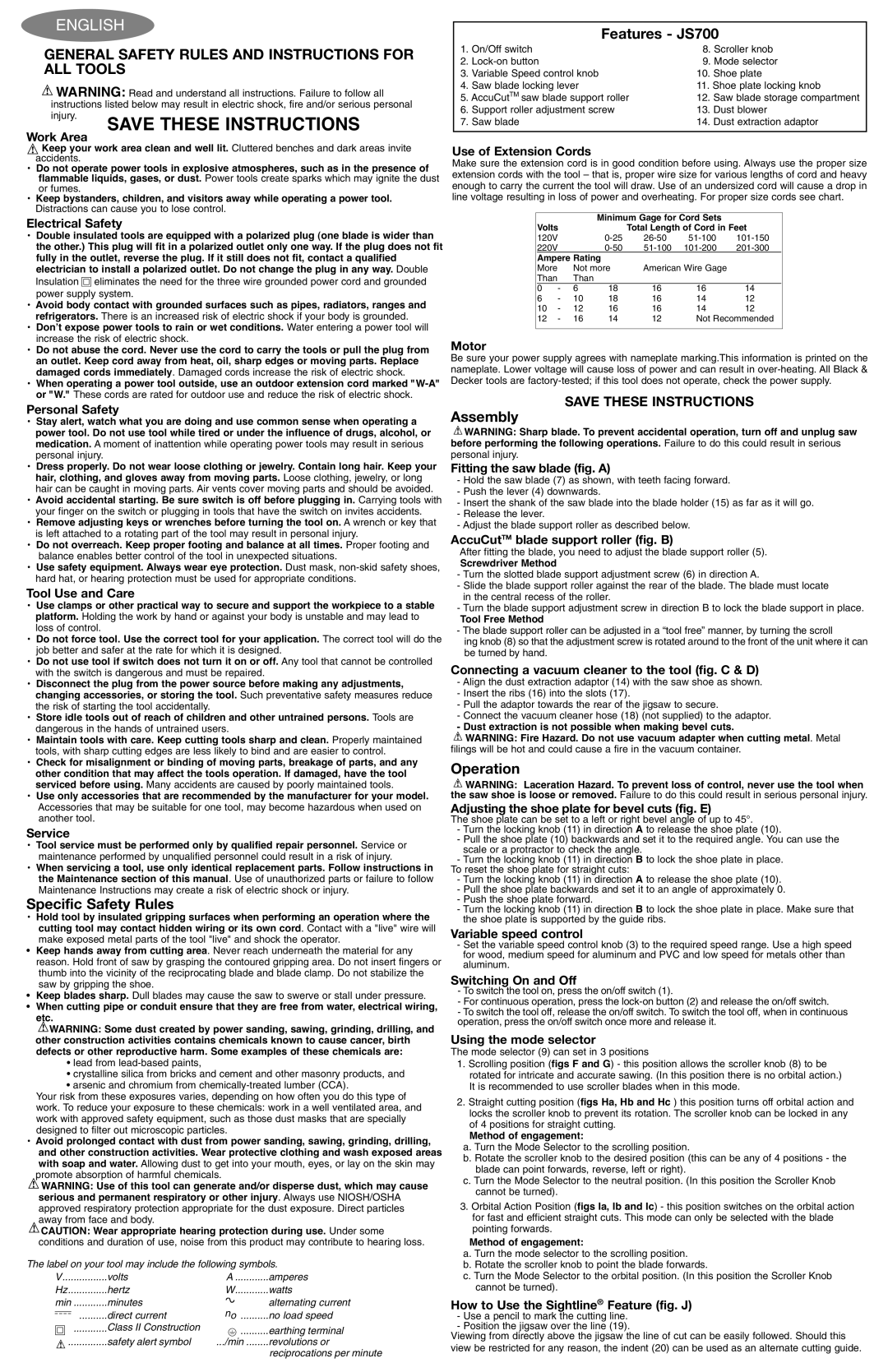

Features - JS700

1. | On/Off switch | 8. Scroller knob |

2. | Lock-on button | 9. Mode selector |

3. | Variable Speed control knob | 10. | Shoe plate |

4. | Saw blade locking lever | 11. | Shoe plate locking knob |

5. | AccuCutTM saw blade support roller | 12. | Saw blade storage compartment |

6. | Support roller adjustment screw | 13. | Dust blower |

7. | Saw blade | 14. | Dust extraction adaptor |

Use of Extension Cords

Make sure the extension cord is in good condition before using. Always use the proper size extension cords with the tool – that is, proper wire size for various lengths of cord and heavy enough to carry the current the tool will draw. Use of an undersized cord will cause a drop in line voltage resulting in loss of power and overheating. For proper size cords see chart.

| Volts | | Minimum Gage for Cord Sets | | |

| | | |

| | | | Total Length of Cord in Feet |

| 120V | | | 0-25 | 26-50 | 51-100 | 101-150 | |

| Ampere Rating | 0-50 | 51-100 | 101-200 | 201-300 | |

| 220V | | | |

| More | | Not more | American Wire Gage | | |

| Than | | Than | | | | | | |

| 0 | - | 6 | | 18 | 16 | 16 | 14 | |

6 | - | 10 | | 18 | 16 | 14 | 12 | |

10 | - | 12 | | 16 | 16 | 14 | 12 | |

12 | - | 16 | | 14 | 12 | Not Recommended |

| | | | | | | | | |

Motor

Be sure your power supply agrees with nameplate marking.This information is printed on the nameplate. Lower voltage will cause loss of power and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does not operate, check the power supply.

SAVE THESE INSTRUCTIONS

Assembly

WARNING: Sharp blade. To prevent accidental operation, turn off and unplug saw before performing the following operations. Failure to do this could result in serious personal injury.

Fitting the saw blade (fig. A)

-Hold the saw blade (7) as shown, with teeth facing forward.

-Push the lever (4) downwards.

-Insert the shank of the saw blade into the blade holder (15) as far as it will go.

-Release the lever.

-Adjust the blade support roller as described below.

AccuCutTM blade support roller (fig. B)

AfterScrewdriverfitting theMethodblade, you need to adjust the blade support roller (5).

-Turn the slotted blade support adjustment screw (6) in direction A.

-Slide the blade support roller against the rear of the blade. The blade must locate in the central recess of the roller.

-ToolTurnFreeth bladeMethodsupport adjustment screw in direction B to lock the blade support in place. - The blade support roller can be adjusted in a “tool free” manner, by turning the scroll

ing knob (8) so that the adjustment screw is rotated around to the front of theunit where it can be turned by hand.

Connecting a vacuum cleaner to the tool (fig. C & D)

- Align the dust extraction adaptor (14) with the saw shoe as shown. - Insert the ribs (16) into the slots (17).

- Pull the adaptor towards the rear of the jigsaw to secure.

- DustConnextractionct the vacuumis notcleanerpossiblehosewhen(18) (notmakingsupplibeveld) tocutsthe. adaptor.

WARNING: Fire Hazard. Do not use vacuum adapter when cutting metal. Metal filings will be hot and could cause a fire in the vacuum container.

WARNING: Fire Hazard. Do not use vacuum adapter when cutting metal. Metal filings will be hot and could cause a fire in the vacuum container.

Operation

WARNING: Laceration Hazard. To prevent loss of control, never use the tool when the saw shoe is loose or removed. Failure to do this could result in serious personal injury.

Adjusting the shoe plate for bevel cuts (fig. E)

The shoe plate can be set to a left or rightAbevel angle of up to 45°.

- Turn the locking knob (11) in direction to release the shoe plate (10).

- Pull the shoe plate (10) backwards and set it to the required angle. You can use the scale or a protractor to check the angleB.

- Turn the locking knob (11) in direction to lock the shoe plate in place. To reset the shoe plate for straight cuts: A

- Turn the locking knob (11) in direction to release the shoe plate (10). - Pull the shoe plate backwards and set it to an angle of approximately 0.

- Push the shoe plate forward. B

- Turn the locking knob (11) in direction to lock the shoe plate in place. Make sure that the shoe plate is supported by the guide ribs.

Variable speed control

-Set the variable speed control knob (3) to the required speed range. Use a high speed for wood, medium speed for aluminum and PVC and low speed for metals other than aluminum.

Switching On and Off

-To switch the tool on, press the on/off switch (1).

-For continuous operation, press thelock-on button (2) and release the on/off switch.

-To switch the tool off,release the on/off switch. To switch thetool off, when in continuous operation, press the on/off switch oncemore and releaseit.

Using the mode selector

The mode selector (9) figscan Fsetandin 3Gpositions

1. Scrolling position () - this position allows the scroller knob (8) to be rotated for intricate and accurate sawing. (In this position there is no orbital action.)

2.Straight cutting position (figs Ha, Hb and Hc ) this position turns off orbital action and locks the scroller knob to prevent its rotation. The scroller knob can be locked in any Methodof 4 p sitionsof engagement:for straigh cutting.

a.Turn the Mode Selector to the scrolling position.

b.Rotate the scroller knob to the desired position (this can be any of 4 positions - the blade can point forwards, reverse, left or right).

c.Turn the Mode Selector to the neutral position. (In this position the Scroller Knob cannot be turned).

3.Orbital Action Position (figs Ia, Ib and Ic) - this position switches on the orbital action for fast and efficient straight cuts. This mode can only be selected with the bladeIt is recommended to use scroller blades when in this mode.

Methodpointingofforwardsengagement:.

a. Turn the mode selector to the scrolling position.

b. Rotate the scroller knob to point the blade forwards.

c. Turn the Mode Selector to the orbital position. (In this position the Scroller Knob cannot be turned).

How to Use the Sightline® Feature (fig. J)

-Use a pencil to mark the cutting line.

-Position the jigsaw over the line (19).

Viewing from directly above the jigsaw the line of cut can be easily followed. Should this view be restricted for any reason, the indent (20) can be used as an alternate cutting guide.