OPERATION

OPERATION

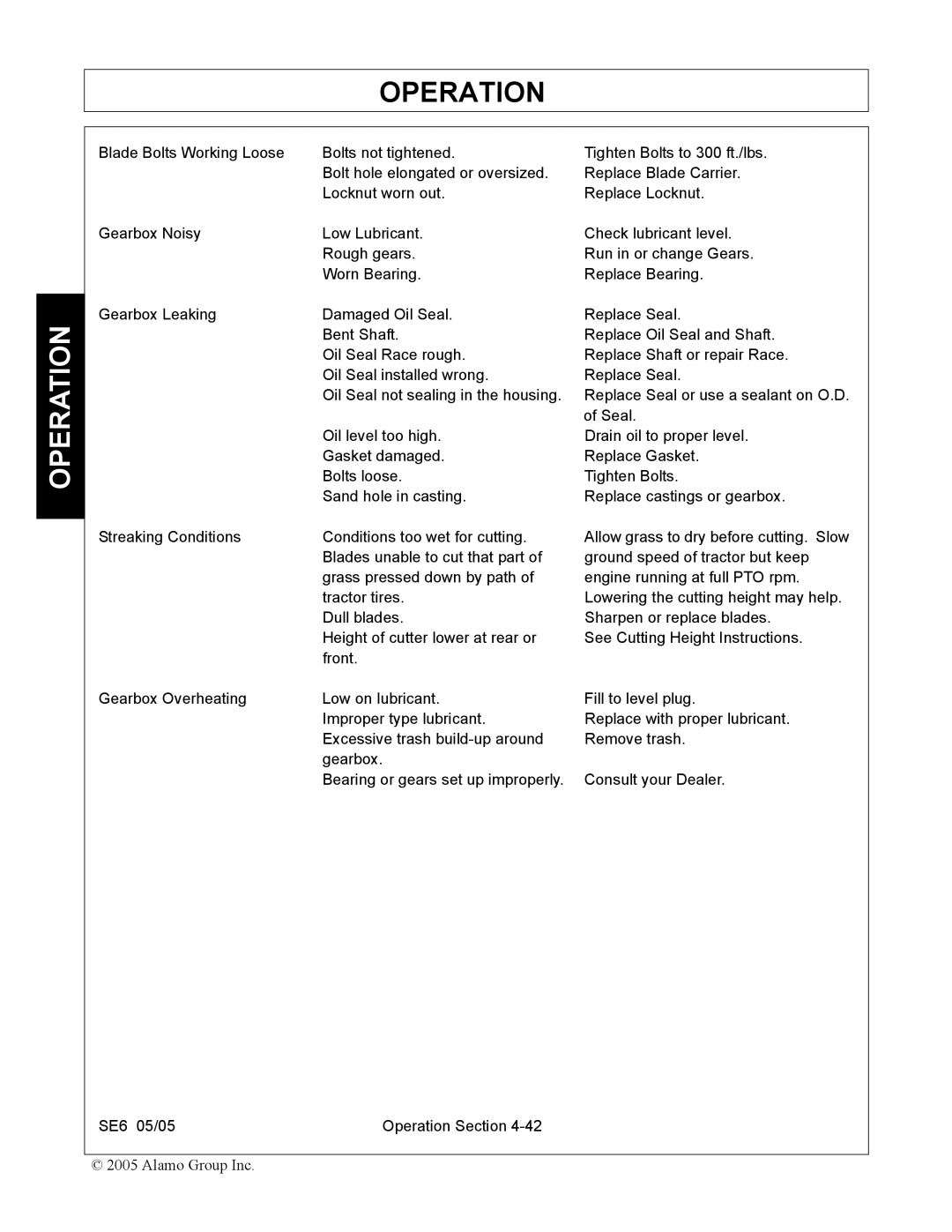

Blade Bolts Working Loose | Bolts not tightened. |

| Bolt hole elongated or oversized. |

| Locknut worn out. |

Gearbox Noisy | Low Lubricant. |

| Rough gears. |

| Worn Bearing. |

Gearbox Leaking | Damaged Oil Seal. |

| Bent Shaft. |

| Oil Seal Race rough. |

| Oil Seal installed wrong. |

| Oil Seal not sealing in the housing. |

| Oil level too high. |

| Gasket damaged. |

| Bolts loose. |

| Sand hole in casting. |

Streaking Conditions | Conditions too wet for cutting. |

| Blades unable to cut that part of |

| grass pressed down by path of |

| tractor tires. |

| Dull blades. |

| Height of cutter lower at rear or |

| front. |

Gearbox Overheating | Low on lubricant. |

| Improper type lubricant. |

| Excessive trash |

| gearbox. |

| Bearing or gears set up improperly. |

Tighten Bolts to 300 ft./lbs.

Replace Blade Carrier.

Replace Locknut.

Check lubricant level.

Run in or change Gears.

Replace Bearing.

Replace Seal.

Replace Oil Seal and Shaft. Replace Shaft or repair Race. Replace Seal.

Replace Seal or use a sealant on O.D. of Seal.

Drain oil to proper level. Replace Gasket. Tighten Bolts.

Replace castings or gearbox.

Allow grass to dry before cutting. Slow ground speed of tractor but keep engine running at full PTO rpm. Lowering the cutting height may help. Sharpen or replace blades.

See Cutting Height Instructions.

Fill to level plug.

Replace with proper lubricant. Remove trash.

Consult your Dealer.

SE6 05/05 | Operation Section |

© 2005 Alamo Group Inc.