OPERATION

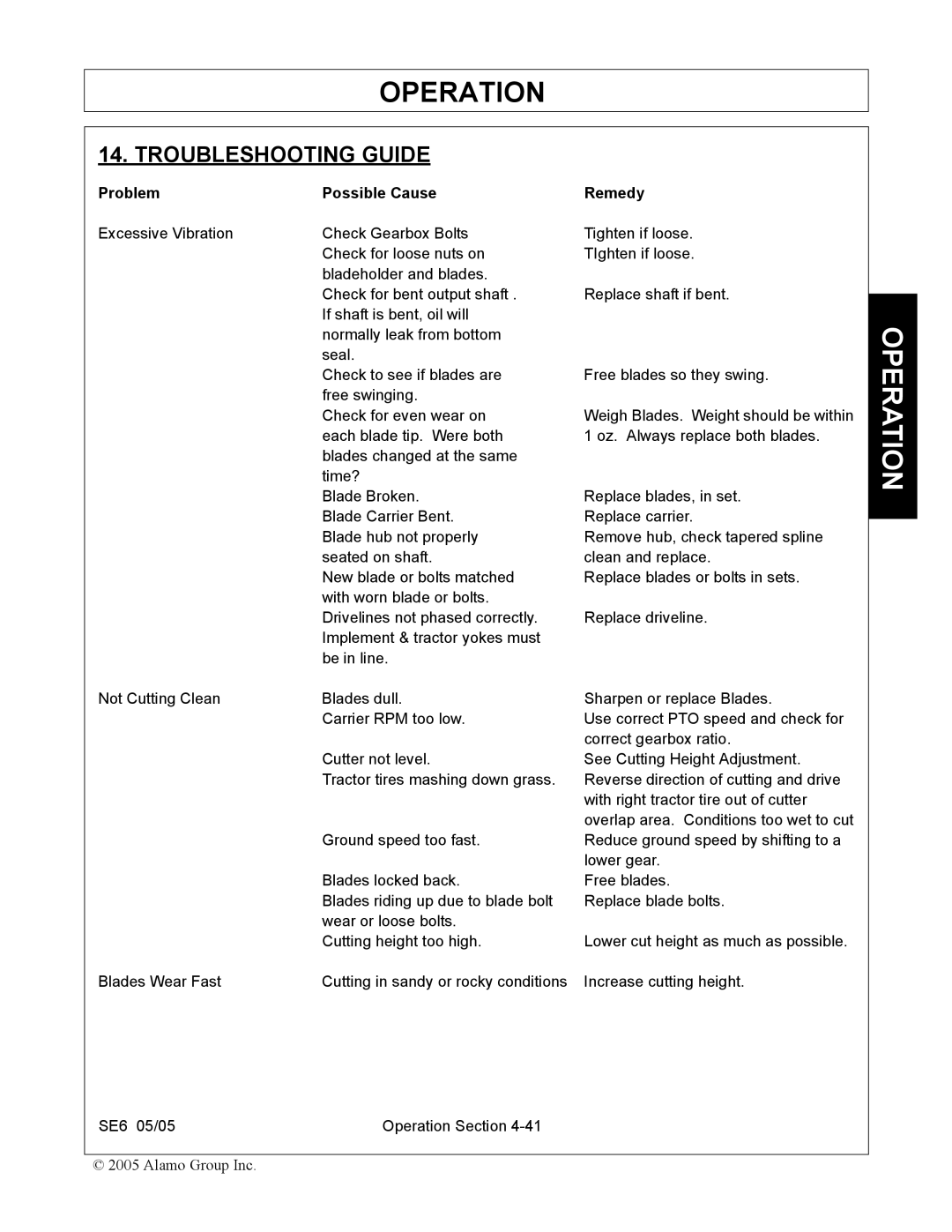

14. TROUBLESHOOTING GUIDE

Problem | Possible Cause | Remedy |

Excessive Vibration | Check Gearbox Bolts | Tighten if loose. |

| Check for loose nuts on | TIghten if loose. |

| bladeholder and blades. |

|

| Check for bent output shaft . | Replace shaft if bent. |

| If shaft is bent, oil will |

|

| normally leak from bottom |

|

| seal. |

|

| Check to see if blades are | Free blades so they swing. |

| free swinging. |

|

| Check for even wear on | Weigh Blades. Weight should be within |

| each blade tip. Were both | 1 oz. Always replace both blades. |

| blades changed at the same |

|

| time? |

|

| Blade Broken. | Replace blades, in set. |

| Blade Carrier Bent. | Replace carrier. |

| Blade hub not properly | Remove hub, check tapered spline |

| seated on shaft. | clean and replace. |

| New blade or bolts matched | Replace blades or bolts in sets. |

| with worn blade or bolts. |

|

| Drivelines not phased correctly. | Replace driveline. |

| Implement & tractor yokes must |

|

| be in line. |

|

Not Cutting Clean | Blades dull. | Sharpen or replace Blades. |

| Carrier RPM too low. | Use correct PTO speed and check for |

|

| correct gearbox ratio. |

| Cutter not level. | See Cutting Height Adjustment. |

| Tractor tires mashing down grass. | Reverse direction of cutting and drive |

|

| with right tractor tire out of cutter |

|

| overlap area. Conditions too wet to cut |

| Ground speed too fast. | Reduce ground speed by shifting to a |

|

| lower gear. |

| Blades locked back. | Free blades. |

| Blades riding up due to blade bolt | Replace blade bolts. |

| wear or loose bolts. |

|

| Cutting height too high. | Lower cut height as much as possible. |

Blades Wear Fast | Cutting in sandy or rocky conditions | Increase cutting height. |

SE6 05/05 | Operation Section |

© 2005 Alamo Group Inc.