5.Each time you use the rider be sure you check the condition of the nuts, bolts, cotter pins, etc. to be sure all are tight and secure properly.

6.The transaxle transmission is

Transmission oil should be changed every 50 hours of operation or once each season.

7.The disc brake pads wear and may require

replaci ng occasionally. Th is replacement is best done by a qualified service dealer.

& CAUTION

Brakes should be kept in good oper- ating condition to avoid possible in- jury or damage to the operator or tractor.

8.Should excessive vibration develop, check for the cause immediately. Check for a damaged

blade, damaged bearing shaft, frayed belt, an obstruction, etc. DO NOT operate the rider again until the cause is found and corrected.

SPARK PLUG

The spark plug gap should be cleaned and reset to

a

the start of each mowing season.

~NOTE

Whenever the spark plug is removed for cleaning, it is advisable to re- place the spark plug gasket with a new gasket.

FIGURE 19. SPARK PLUG CLEARANCE

REPLACING BLADE

)

) (:~~~~~~j

(:~~~~~~j

Before beginning work on the cutterblade, remove the spark plug fromthe

cylinder.

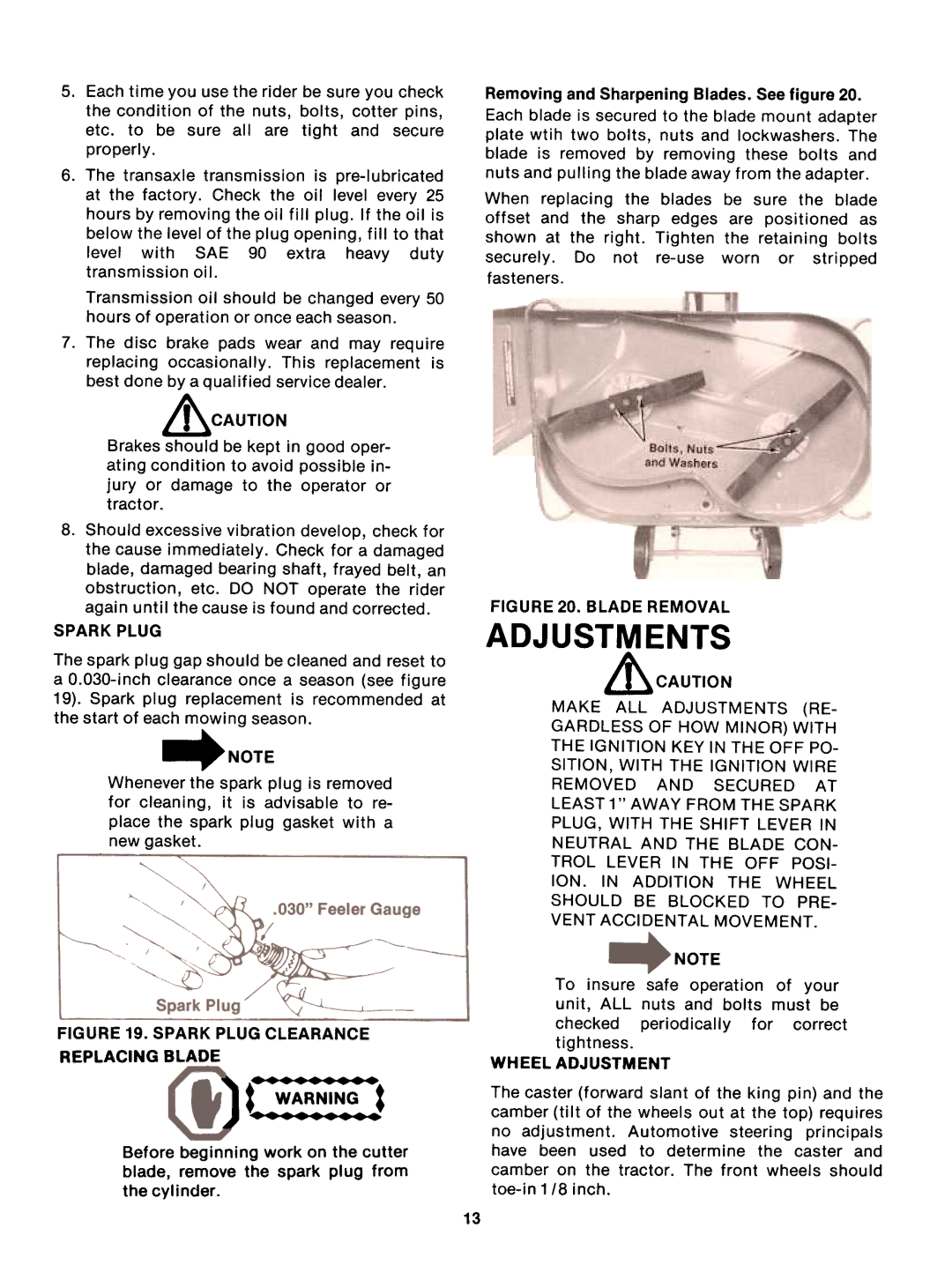

Removing and Sharpening Blades. See figure 20.

Each blade is secured to the blade mount adapter

plate wtih two bolts, nuts and lockwashers. The blade is removed by removing these bolts and nuts and pulling the blade away from the adapter.

When replacing the blades be sure the blade

offset and the sharp edges are positioned as

shown at the right. Tighten the retaining boltssecurely. Do not

fasteners.

FIGURE 20. BLADE REMOVALADJUSTMENTS

~CAUTION

MAKE ALL ADJUSTMENTS (RE-

GARDLESS OF HOW MINOR) WITH

THE IGNITION KEY IN THE OFF PO-

SITION, WITH THE IGNITION WIRE

REMOVED AND SECURED AT

LEAST 1 " AWAY FROM THE SPARK

PLUG, WITH THE SHIFT LEVER IN

NEUTRAL AND THE BLADE CON-

TROL LEVER IN THE OFF POSI-

ION. IN ADDITION THE WHEEL

SHOULD BE BLOCKED TO PRE-

VENT ACCIDENTAL MOVEMENT.

NOTE

To insure safe operation of your unit, ALL nuts and bolts must be

checked periodically for correct

tightness.

WHEEL ADJUSTMENT

The caster (forward slant of the king pin) and the camber (tilt of the wheels out at the top) requires

no adjustment. Automotive steering principals have been used to determine the caster and camber on the tractor. The front wheels should

13