lock is engaged. NOTE: The PTO switch must be moved to the “OFF” position to restart the engine.

•The safety interlock system will shut off the PTO if the reverse control pedal is depressed, unless the reverse override function is activated. NOTE: If the reverse override function has been activated, it will remain activated until the ignition switch is turned to the "OFF" position for a 20 second duration.

FUELING THE TRACTOR

Fill the fuel tank with only clean, fresh, diesel fuel with a minimum cetane number of 40. To ensure the freshness of the fuel, purchase fuel in a quantity that can be used within 30 days.

NOTE: DO NOT USE KEROSENE OR GASOLINE in your diesel engine. Damage to the engine will occur.

Generally a good grade Number Two Diesel Fuel should be used in your diesel engine. In extremely cold temperatures a quality Number One Diesel Fuel, or a blend of the two, should be used. In most areas, diesel fuel is properly blended for seasonal use as ambient temperatures change. Therefore, it is important to monitor fuel purchases so that seasonal grade fuels are not carried over after the average ambient temperature has changed.

WARNING: Never fill the fuel tank to the top of the filler neck. Expansion could result in overflow through the vents in the cap, allowing fuel to come in contact with the operator.

•Do not smoke while refueling the tractor.

•Do not fill the fuel tank when the engine is running or while the engine is hot.

•The fuel fill cap is located on the fender to the left of the seat. Unscrew the fuel cap and fill tank from an approved container. Do not fill the fuel tank to capacity. Allow room for expansion.

•Tighten the fuel cap securely, and immediately wipe up any spilled fuel.

•To minimize condensation, keep the fuel tank as full as possible without filling to capacity. It is a good practice to fill the fuel tank at the end of the day to reduce overnight condensation.

•Do not allow the fuel tank to run dry. Running out of fuel requires bleeding air and repriming the fuel system.

WARNING: Fuel in the engine injection system is under high pressure. If not a qualified mechanic, do not attempt to service the fuel injection system. Do not use your hand to check for leaks.

NEW TRACTOR BREAK-IN PROCEDURES

Proper care in the first hours of operation will help to assure optimal performance of your new tractor.

•Never operate a new engine immediately under full load. Allow the engine to warm up.

•Avoid operating the engine for prolonged periods at either high or low speed with no load.

•Use the transmission’s low speed range for heavy loads to avoid lugging, or stalling, of the engine due to overload.

•Closely monitor the engine oil and keep filled to the recommended level.

•After the first ten hours of operation, check the front and rear wheel lug nuts. If necessary, re- torque the lug nuts to

•Perform all

STARTING THE ENGINE

WARNING: Always sit in the operator’s seat when starting the tractor, Never attempt to start the engine while standing beside the tractor.

WARNING: Never use starting fluids, such as ether, as a starting aid. Severe engine damage or fire could result.

•Operator must be sitting in the tractor seat.

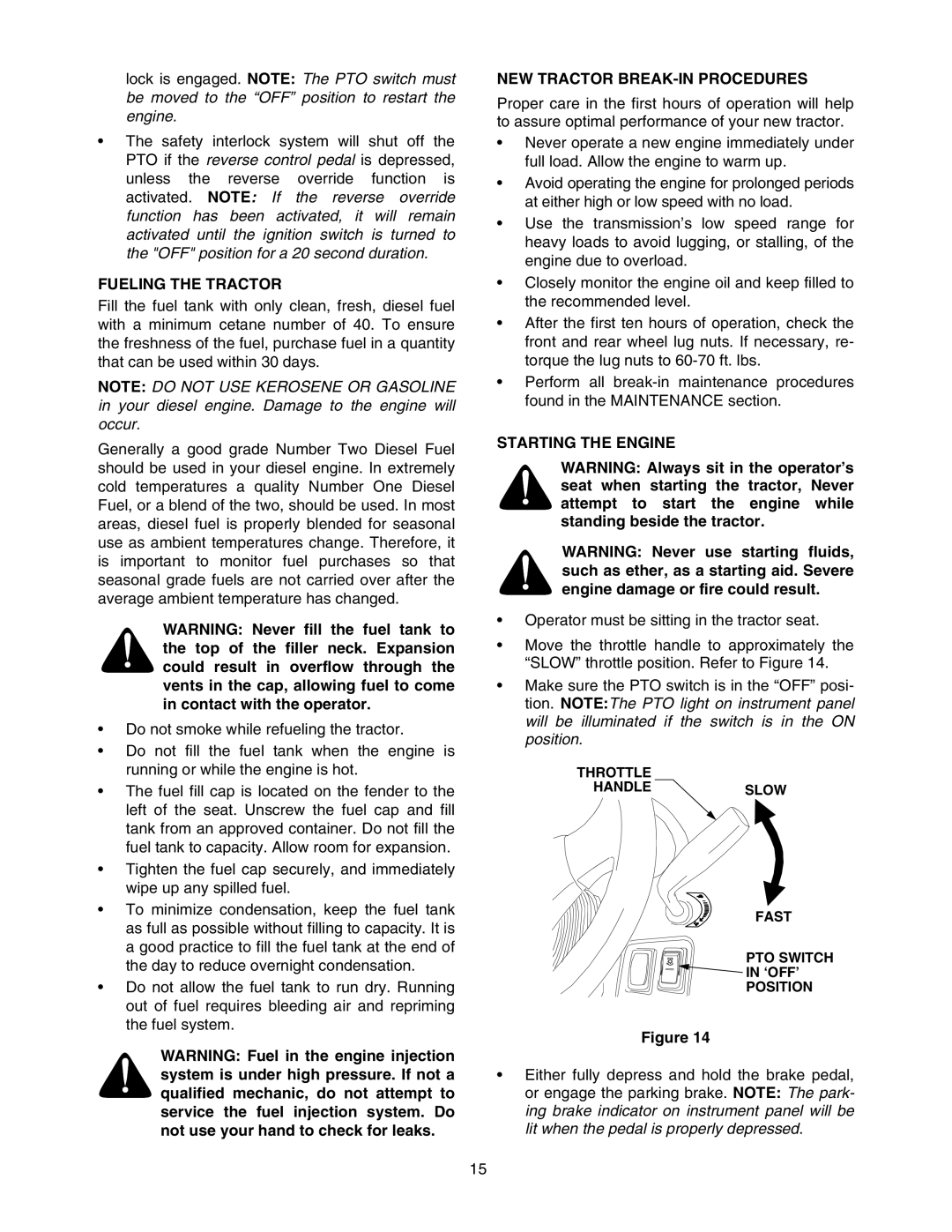

•Move the throttle handle to approximately the “SLOW” throttle position. Refer to Figure 14.

•Make sure the PTO switch is in the “OFF” posi- tion. NOTE:The PTO light on instrument panel will be illuminated if the switch is in the ON position.

THROTTLE

HANDLESLOW

FAST

PTO SWITCH

![]()

![]()

![]()

![]()

![]()

![]()

![]() IN ‘OFF’

IN ‘OFF’

POSITION

Figure 14

•Either fully depress and hold the brake pedal, or engage the parking brake. NOTE: The park- ing brake indicator on instrument panel will be lit when the pedal is properly depressed.

15