To create a joint, contact cement should be applied to the core material and the plastic laminate, and one piece of laminate should be fastened to the core with the other overlapping it by about 3/4". The fixed piece must have a clean, straight edge as it will serve as a guide for the underscribe base to follow. The over- lapping sheet of laminate will then pass over the aluminum plate and be cut to the proper length by the router bit. (See Figure 14). This

Fig. 14

accurate system makes it a perfect tool for joining laminate on stile and rail constructions, circular or curved edges, and many other sur- faces. Because the cutter will generate chips, it is necessary to keep the laminate pressed down tightly near the seam to keep these chips from getting into the

Fig. 15

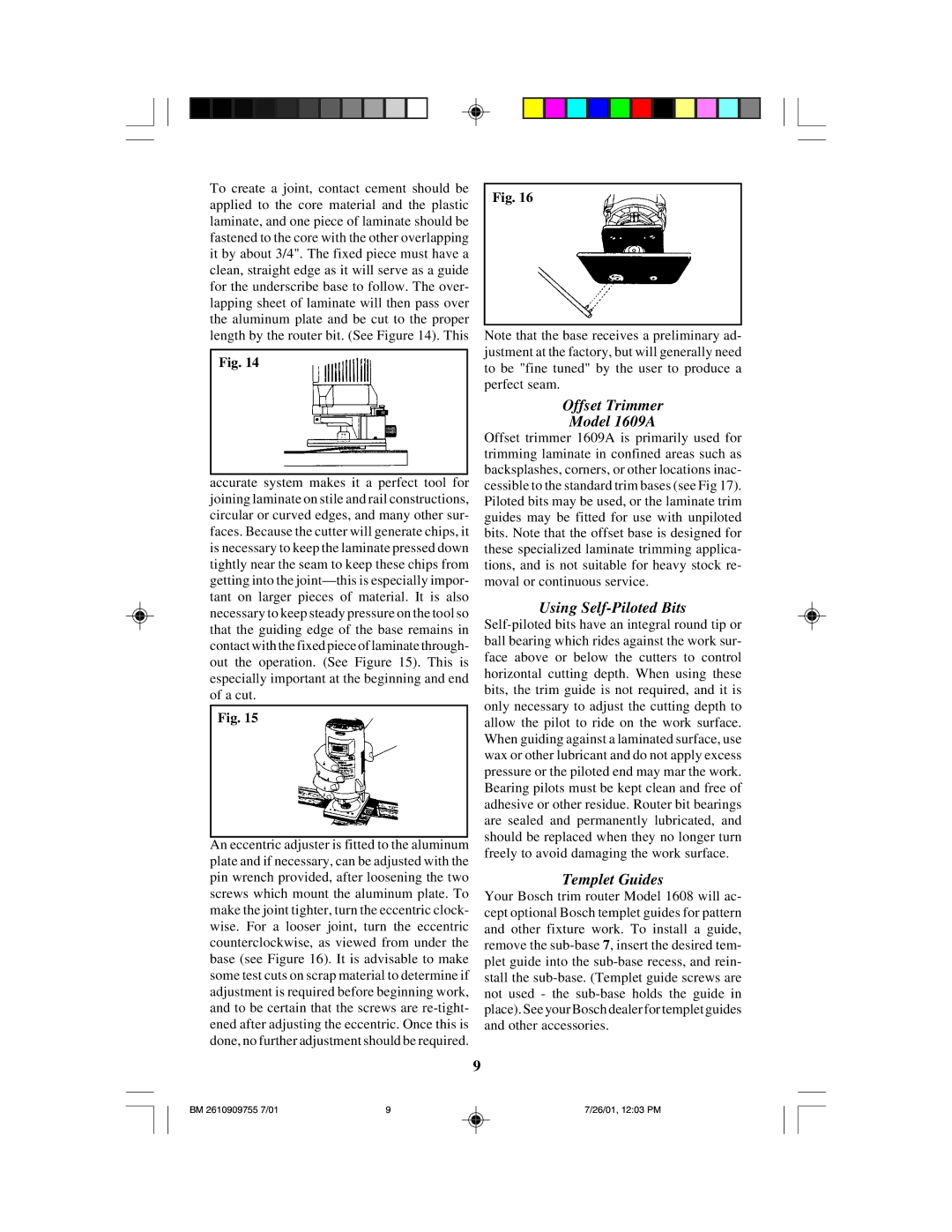

An eccentric adjuster is fitted to the aluminum plate and if necessary, can be adjusted with the pin wrench provided, after loosening the two screws which mount the aluminum plate. To make the joint tighter, turn the eccentric clock- wise. For a looser joint, turn the eccentric counterclockwise, as viewed from under the base (see Figure 16). It is advisable to make some test cuts on scrap material to determine if adjustment is required before beginning work, and to be certain that the screws are

Fig. 16

Note that the base receives a preliminary ad- justment at the factory, but will generally need to be "fine tuned" by the user to produce a perfect seam.

Offset Trimmer

Model 1609A

Offset trimmer 1609A is primarily used for trimming laminate in confined areas such as backsplashes, corners, or other locations inac- cessible to the standard trim bases (see Fig 17). Piloted bits may be used, or the laminate trim guides may be fitted for use with unpiloted bits. Note that the offset base is designed for these specialized laminate trimming applica- tions, and is not suitable for heavy stock re- moval or continuous service.

Using Self-Piloted Bits

Templet Guides

Your Bosch trim router Model 1608 will ac- cept optional Bosch templet guides for pattern and other fixture work. To install a guide, remove the

9

BM 2610909755 7/01 | 9 | 7/26/01, 12:03 PM |