BM 1609929J65 01-11:BM 1609929J65 01-11 1/20/11 10:41 AM Page 14

PADDLE SWITCH WITH

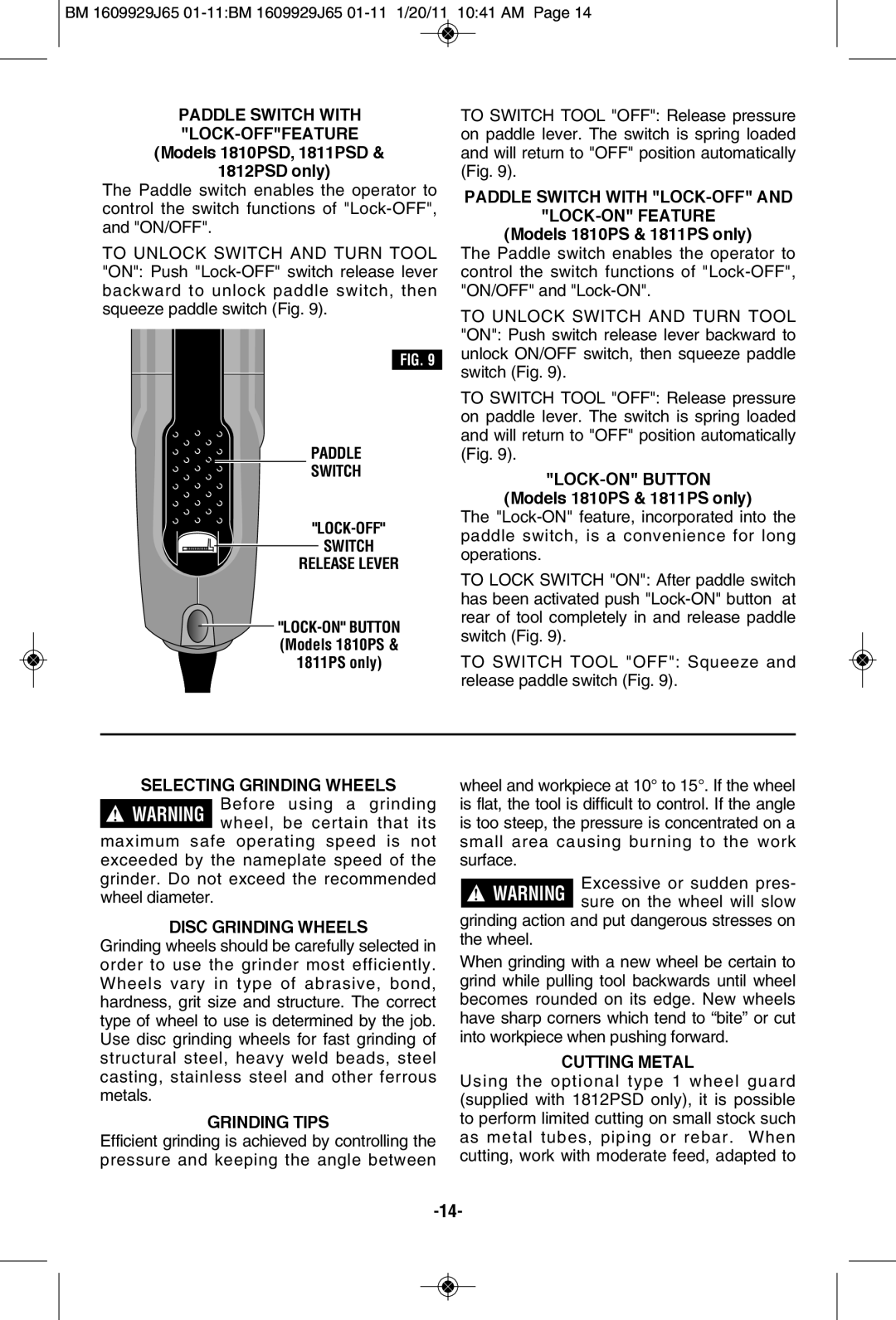

The Paddle switch enables the operator to control the switch functions of

TO UNLOCK SWITCH AND TURN TOOL "ON": Push

FIG. 9

PADDLE

SWITCH

"LOCK-OFF"

SWITCH

RELEASE LEVER

![]()

1811PS only)

TO SWITCH TOOL "OFF": Release pressure on paddle lever. The switch is spring loaded and will return to "OFF" position automatically (Fig. 9).

PADDLE SWITCH WITH "LOCK-OFF" AND

"LOCK-ON" FEATURE

(Models 1810PS & 1811PS only)

The Paddle switch enables the operator to control the switch functions of

TO UNLOCK SWITCH AND TURN TOOL "ON": Push switch release lever backward to unlock ON/OFF switch, then squeeze paddle switch (Fig. 9).

TO SWITCH TOOL "OFF": Release pressure on paddle lever. The switch is spring loaded and will return to "OFF" position automatically (Fig. 9).

"LOCK-ON" BUTTON

(Models 1810PS & 1811PS only)

The

TO LOCK SWITCH "ON": After paddle switch has been activated push

TO SWITCH TOOL "OFF": Squeeze and release paddle switch (Fig. 9).

SELECTING GRINDING WHEELS Before using a grinding wheel, be certain that its

maximum safe operating speed is not exceeded by the nameplate speed of the grinder. Do not exceed the recommended wheel diameter.

DISC GRINDING WHEELS

Grinding wheels should be carefully selected in order to use the grinder most efficiently. Wheels vary in type of abrasive, bond, hardness, grit size and structure. The correct type of wheel to use is determined by the job. Use disc grinding wheels for fast grinding of structural steel, heavy weld beads, steel casting, stainless steel and other ferrous metals.

GRINDING TIPS

Efficient grinding is achieved by controlling the pressure and keeping the angle between

wheel and workpiece at 10° to 15°. If the wheel is flat, the tool is difficult to control. If the angle is too steep, the pressure is concentrated on a small area causing burning to the work surface.

Excessive or sudden pres- ! WARNING sure on the wheel will slow

grinding action and put dangerous stresses on the wheel.

When grinding with a new wheel be certain to grind while pulling tool backwards until wheel becomes rounded on its edge. New wheels have sharp corners which tend to “bite” or cut into workpiece when pushing forward.

CUTTING METAL

Using the optional type 1 wheel guard (supplied with 1812PSD only), it is possible to perform limited cutting on small stock such as metal tubes, piping or rebar. When cutting, work with moderate feed, adapted to