DM 2610919361 9/03 9/5/03 8:33 AM Page 9

SELECTING ABRASIVES

The following suggestions may be used as a general guide for abrasive selection, but the best results will be obtained by sanding a test sample of the workpiece first.

Grit | Application |

Coarse | For rough wood, metal sanding, |

80 grit | rust, paint, or old material removal. |

Medium | For general wood or metal sanding. |

120 grit |

|

Extra fine | For final sanding of bare wood, |

220 grit | smoothing old paint, or preparing a |

| finished surface for recoating. |

With the workpiece firmly secured, turn tool “ON”. Contact the work with the tool after the sander has reached the selected speed, and remove it from the work before switching the tool “OFF”. Operating your sander in this manner will prolong switch and motor life, and greatly increase the quality of your work.

Your contour sander uses an

achieved while operating the sander

DO NOT APPLY EXCESSIVE PRESSURE — LET THE TOOL DO THE WORK. EXCESSIVE PRESSURE WILL RESULT IN POOR HANDLING, VIBRATION, AND UNWANTED SANDING MARKS.

If the surface is rough, begin with coarser grits and then complete the surfacing with medium and fine abrasives. To avoid uneven results, do not skip more than one grit size when going from coarser to finer, and do not sand in one area for too long. When the job is completed, gently lift the tool from the work surface and slide switch to the "OFF" position.

To ensure longer life and even wear, lightly brush any residue or clogged materials from sandpaper surface prior to each use.

!WARNING Do not wet sand with this sander.

Maintenance

Service

Preventive maintenance

!WARNING performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Dremel Service Facility.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brushes be examined. Only genuine Dremel replacement brushes specially designed for your tool should be used.

MAINTENANCE OF

REPLACEABLE BRUSHES #5090930

The brushes should be inspected frequently when tools are used continuously. If your tool runs sporadically, loses power, makes unusual noises or runs at a reduced speed, check the brushes. To continue using the tool in this condition will permanently damage your tool.

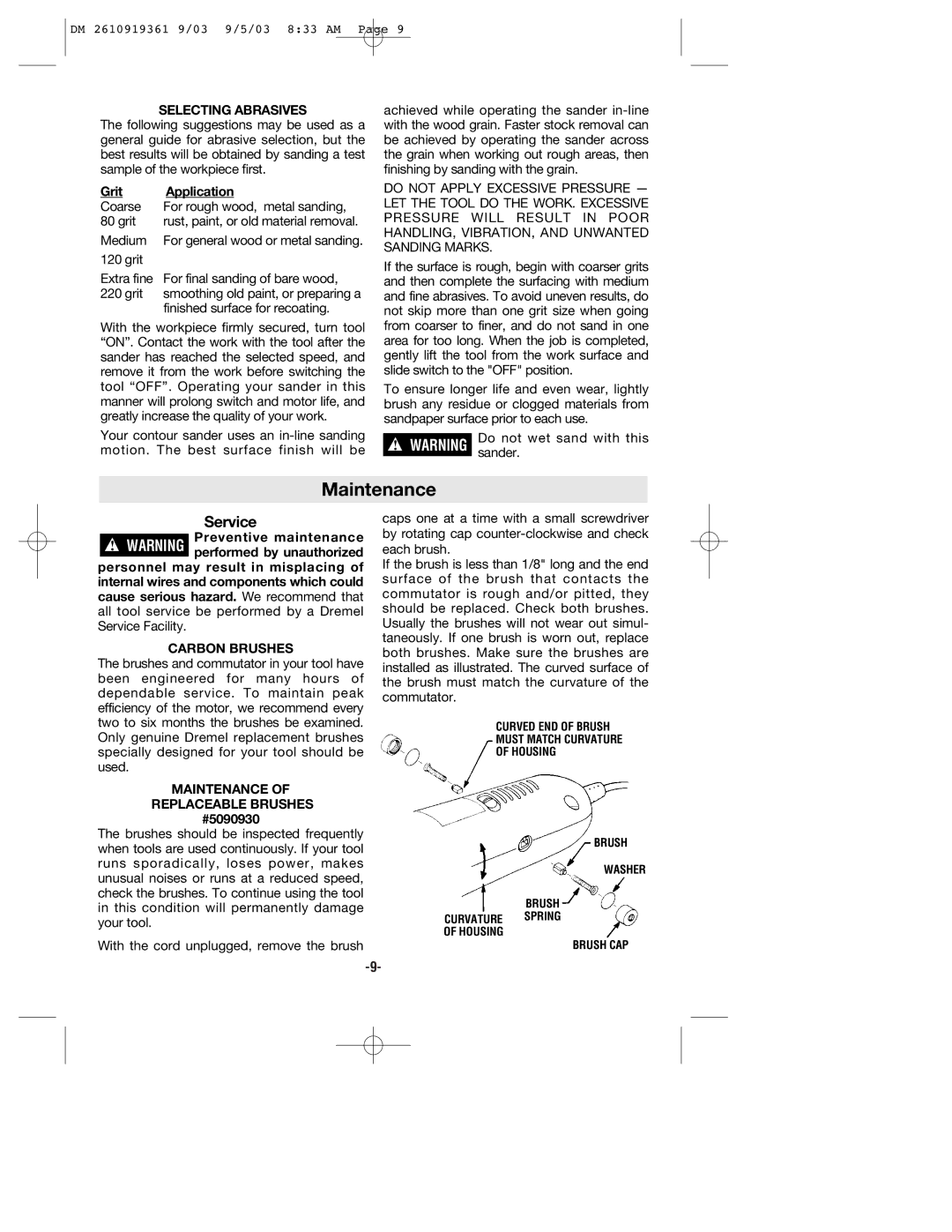

With the cord unplugged, remove the brush

caps one at a time with a small screwdriver by rotating cap

If the brush is less than 1/8" long and the end surface of the brush that contacts the commutator is rough and/or pitted, they should be replaced. Check both brushes. Usually the brushes will not wear out simul- taneously. If one brush is worn out, replace both brushes. Make sure the brushes are installed as illustrated. The curved surface of the brush must match the curvature of the commutator.

CURVED END OF BRUSH

MUST MATCH CURVATURE

OF HOUSING

BRUSH

WASHER

BRUSH

CURVATURE SPRING

OF HOUSING

BRUSH CAP