![]() BM 1619X08893

BM 1619X08893

Maintenance

To avoid accidents always disconnect the tool from the power supply before cleaning or performing any maintenance.

Service

Preventive maintenance

!WARNING performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch Factory Service Center or Authorized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated and is ready to use. However it is recommended that the gears be relubricated only with Bosch lubricant: WD7LUB or Skil 80111.

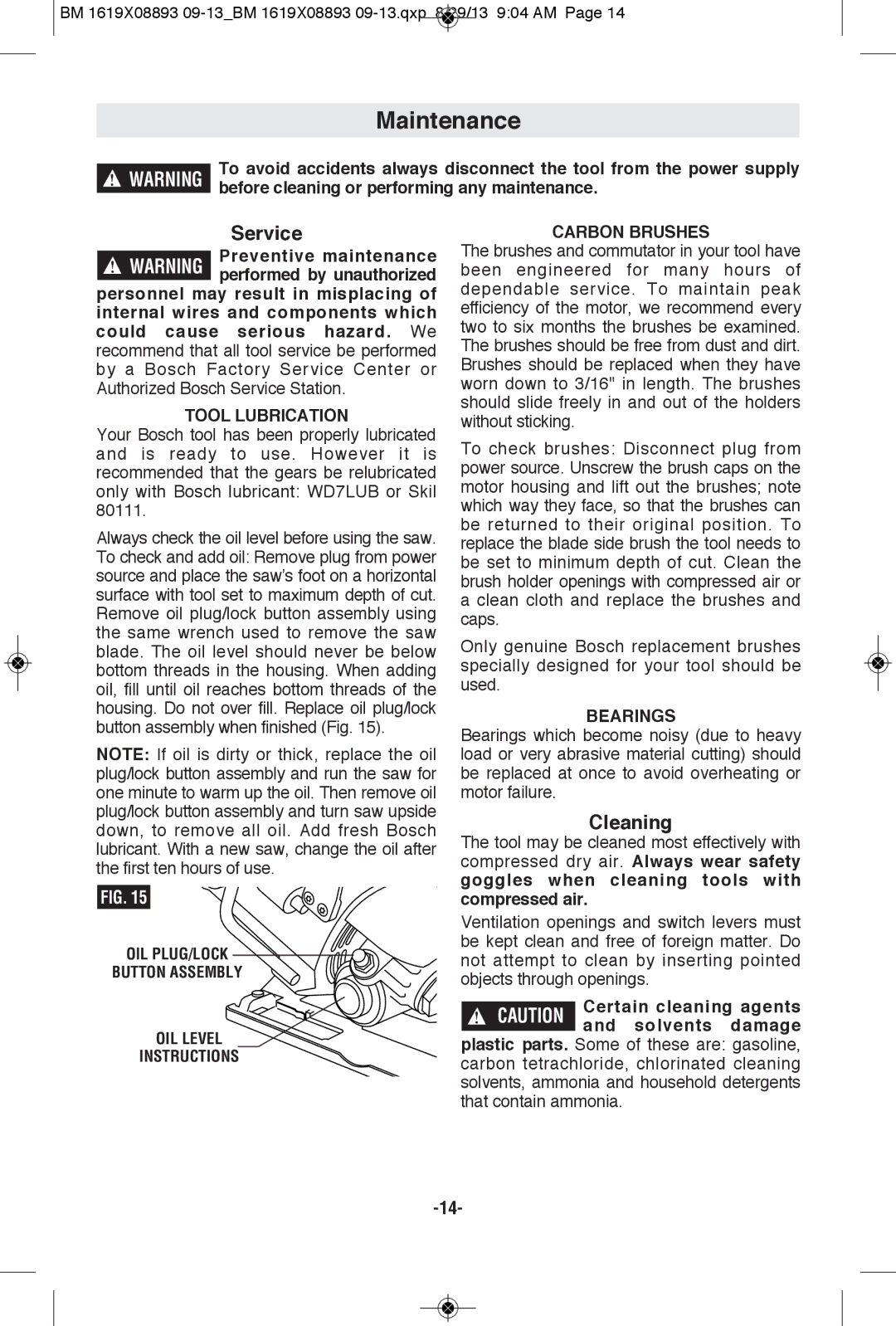

Always check the oil level before using the saw. To check and add oil: Remove plug from power source and place the saw’s foot on a horizontal surface with tool set to maximum depth of cut. Remove oil plug/lock button assembly using the same wrench used to remove the saw blade. The oil level should never be below bottom threads in the housing. When adding oil, fill until oil reaches bottom threads of the housing. Do not over fill. Replace oil plug/lock button assembly when finished (Fig. 15).

NOTE: If oil is dirty or thick, replace the oil plug/lock button assembly and run the saw for one minute to warm up the oil. Then remove oil plug/lock button assembly and turn saw upside down, to remove all oil. Add fresh Bosch lubricant. With a new saw, change the oil after the first ten hours of use.

FIG. 15

OIL PLUG/LOCK

BUTTON ASSEMBLY

OIL LEVEL

INSTRUCTIONS

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brushes be examined. The brushes should be free from dust and dirt. Brushes should be replaced when they have worn down to 3/16" in length. The brushes should slide freely in and out of the holders without sticking.

To check brushes: Disconnect plug from power source. Unscrew the brush caps on the motor housing and lift out the brushes; note which way they face, so that the brushes can be returned to their original position. To replace the blade side brush the tool needs to be set to minimum depth of cut. Clean the brush holder openings with compressed air or a clean cloth and replace the brushes and caps.

Only genuine Bosch replacement brushes specially designed for your tool should be used.

BEARINGS

Bearings which become noisy (due to heavy load or very abrasive material cutting) should be replaced at once to avoid overheating or motor failure.

Cleaning

The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

!CAUTION Certain cleaning agents and solvents damage

plastic parts. Some of these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.