OPERATION

WARNING!

To reduce the risk of personal injury, always wear eye protection.

Using Clutch (Fig. 3)

This tool has an adjustable clutch for driving different types of screws into different materials. When properly adjusted, the clutch will slip at a preset torque to prevent driving the screw too deep and to prevent damage to the screw or tool. Refer to the table below to select the correct position for the type of material and screw size you are using.

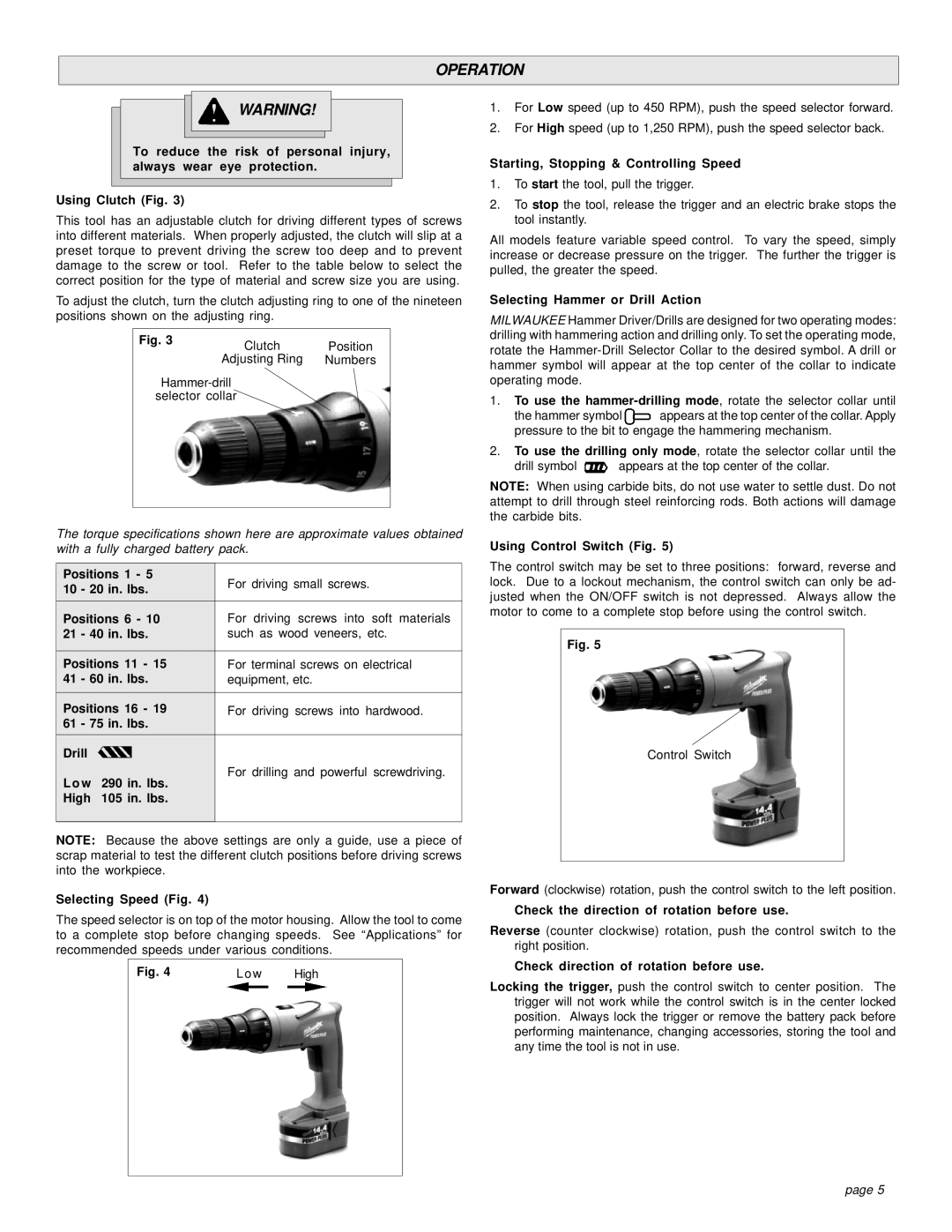

1.For Low speed (up to 450 RPM), push the speed selector forward.

2.For High speed (up to 1,250 RPM), push the speed selector back.

Starting, Stopping & Controlling Speed

1.To start the tool, pull the trigger.

2.To stop the tool, release the trigger and an electric brake stops the tool instantly.

All models feature variable speed control. To vary the speed, simply increase or decrease pressure on the trigger. The further the trigger is pulled, the greater the speed.

To adjust the clutch, turn the clutch adjusting ring to one of the nineteen positions shown on the adjusting ring.

Fig. 3 | Clutch | Position |

| Adjusting Ring | Numbers |

selector collar

The torque specifications shown here are approximate values obtained with a fully charged battery pack.

Positions 1 - 5 | For driving small screws. | |||

10 | - 20 in. lbs. | |||

| ||||

Positions 6 - 10 | For driving screws into soft materials | |||

21 | - 40 in. lbs. | such as wood veneers, etc. | ||

|

| |||

Positions 11 - 15 | For terminal screws on electrical | |||

41 | - 60 in. lbs. | equipment, etc. | ||

|

| |||

Positions 16 - 19 | For driving screws into hardwood. | |||

61 | - 75 in. lbs. |

| ||

Drill |

|

| ||

L o w | 290 in. lbs. | For drilling and powerful screwdriving. | ||

| ||||

High | 105 in. lbs. |

| ||

|

|

|

| |

NOTE: Because the above settings are only a guide, use a piece of scrap material to test the different clutch positions before driving screws into the workpiece.

Selecting Speed (Fig. 4)

The speed selector is on top of the motor housing. Allow the tool to come to a complete stop before changing speeds. See “Applications” for recommended speeds under various conditions.

Fig. 4 | Low |

| High |

|

|

|

|

Selecting Hammer or Drill Action

MILWAUKEE Hammer Driver/Drills are designed for two operating modes: drilling with hammering action and drilling only. To set the operating mode, rotate the

1.To use the

the hammer symbol ![]() appears at the top center of the collar. Apply pressure to the bit to engage the hammering mechanism.

appears at the top center of the collar. Apply pressure to the bit to engage the hammering mechanism.

2.To use the drilling only mode, rotate the selector collar until the

drill symbol ![]() appears at the top center of the collar.

appears at the top center of the collar.

NOTE: When using carbide bits, do not use water to settle dust. Do not attempt to drill through steel reinforcing rods. Both actions will damage the carbide bits.

Using Control Switch (Fig. 5)

The control switch may be set to three positions: forward, reverse and lock. Due to a lockout mechanism, the control switch can only be ad- justed when the ON/OFF switch is not depressed. Always allow the motor to come to a complete stop before using the control switch.

Fig. 5

Control Switch

Forward (clockwise) rotation, push the control switch to the left position.

Check the direction of rotation before use.

Reverse (counter clockwise) rotation, push the control switch to the right position.

Check direction of rotation before use.

Locking the trigger, push the control switch to center position. The trigger will not work while the control switch is in the center locked position. Always lock the trigger or remove the battery pack before performing maintenance, changing accessories, storing the tool and any time the tool is not in use.

page 5